Pumpkin yoghourt and preparation method thereof

A pumpkin and yogurt technology, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of intolerance to storage, short growth cycle of pumpkin, etc., achieve convenience in eating, extend shelf life, and improve human resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

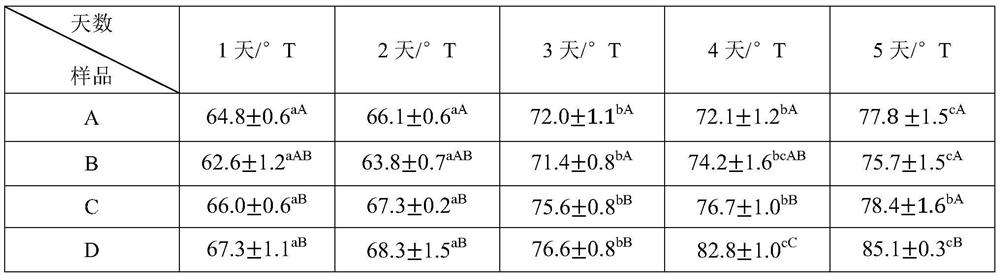

Image

Examples

Embodiment 1

[0040]A pumpkin yoghurt, the formula of which comprises the following raw materials in mass ratio: 15% of pumpkin, 0.2% of Yunzhi polysaccharide, 78% of fresh milk, 5% of white sugar, 1% of starter, 0.50% of compound stabilizer, and the rest is water . The composition of the composite stabilizer is 0.3% of sodium carboxymethyl cellulose, 0.05% of xanthan gum and 0.15% of pectin. The starter is prepared by Lactobacillus bulgaricus and Streptococcus thermophilus in a ratio of 1:1.

[0041] Making the above-mentioned pumpkin polysaccharide yogurt rich in dietary fiber includes the following steps:

[0042] (1) It is carried out in a clean room with a cleanliness of 100. After cleaning and removing dirt such as mud on the surface of the pumpkin, it is cut. Remove the pumpkin fruit stalk, cut off the hard outer skin and inner pulp, seeds, etc., and cut into 3-4 cm thick blocks; put the pumpkin in boiling water for 12 minutes; press the pumpkin slices after blanching: water =Add ...

Embodiment 2

[0050] A pumpkin yoghurt, the formula of which comprises the following raw materials in mass ratio: 18% of pumpkin, 0.3% of Yunzhi polysaccharide, 75% of fresh milk, 5% of white sugar, 1% of starter, 0.50% of compound stabilizer, and the rest is water . The composition of the composite stabilizer is 0.3% of sodium carboxymethyl cellulose, 0.05% of xanthan gum and 0.15% of pectin. The starter is prepared by Lactobacillus bulgaricus and Streptococcus thermophilus in a ratio of 1:1.

[0051] Making the above-mentioned pumpkin polysaccharide yogurt rich in dietary fiber includes the following steps:

[0052] (1) It is carried out in a clean room with a cleanliness of 100. After cleaning and removing dirt such as mud on the surface of the pumpkin, it is cut. Remove the pumpkin fruit stalk, cut off the hard outer skin and inner pulp, seeds, etc., and cut into 3-4 cm thick blocks; put the pumpkin in boiling water for 12 minutes; press the pumpkin slices after blanching: water =Add...

Embodiment 3

[0060] A kind of pumpkin yoghurt, its formula comprises the raw material of following mass ratio: 20% of pumpkin, 0.4% of Yunzhi polysaccharide, 72% of fresh milk, 5% of white granulated sugar, 1% of starter, 0.50% of compound stabilizer, the rest is water . The composition of the composite stabilizer is 0.3% of sodium carboxymethyl cellulose, 0.05% of xanthan gum and 0.15% of pectin. The starter is prepared by Lactobacillus bulgaricus and Streptococcus thermophilus in a ratio of 1:1.

[0061] Making the above-mentioned pumpkin polysaccharide yogurt rich in dietary fiber includes the following steps:

[0062] (1) It is carried out in a clean room with a cleanliness of 100. After cleaning and removing dirt such as mud on the surface of the pumpkin, it is cut. Remove the pumpkin fruit stalk, cut off the hard outer skin and inner pulp, seeds, etc., and cut into 3-4 cm thick blocks; put the pumpkin in boiling water for 12 minutes; press the pumpkin slices after blanching: water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com