Rectification device for preparing electronic grade carbon tetrafluoride

A carbon tetrafluoride, electronic-grade technology, applied in the direction of preparation of halogenated hydrocarbons, fractionation, organic chemistry, etc., can solve the problem that the structural structure and control strategy, design principle, and design application of the undisclosed functional components cannot be realized, and the precision control cannot be stably controlled. Problems such as the temperature of the distillation tower can be solved to achieve the effects of energy saving, high-efficiency rectification, and improvement of the structure of the condenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

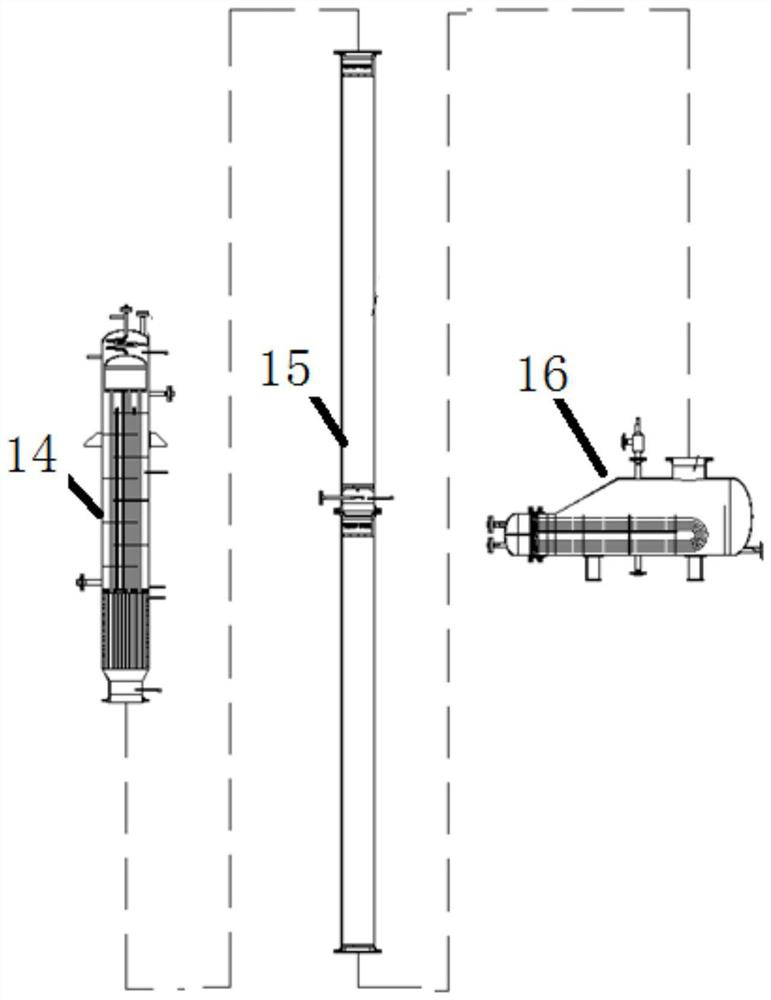

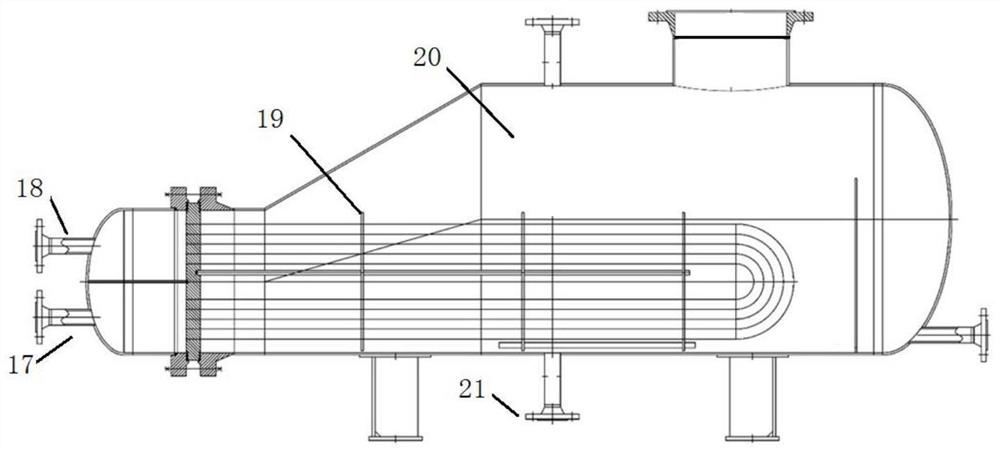

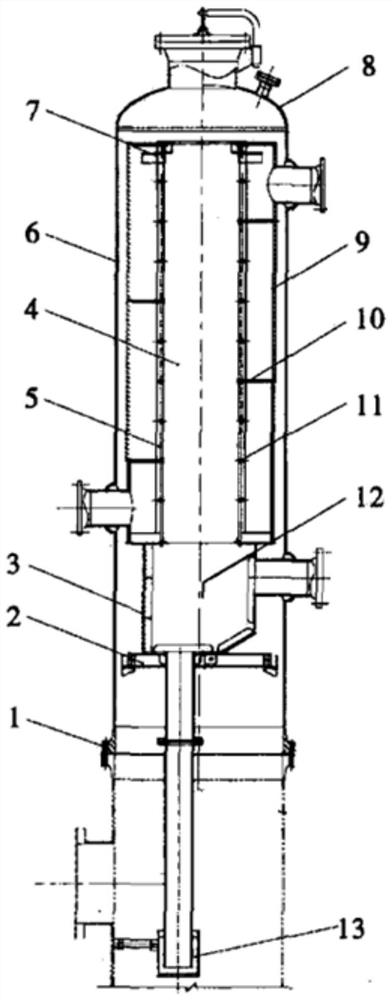

[0027] The rectifying device for preparing electronic-grade carbon tetrafluoride disclosed by the present invention is substantially the same in structure as the rectifying device structure of a utility model patent that the applicant has applied for, so the present invention is attached Figure 1-2 And the structural description of the rectifying device mostly adopts the content therein, but, the rectifying device of the present invention is relative to the rectifying device applied by the applicant, in terms of details, its structure, structure and design method are all different with it, Therefore, the present invention is obtained through the creative efforts of those skilled in the art on the basis of the prior art (the prior art also belongs to the content disclosed by the applicant). In the following, we describe the same technical features of the present invention as the prior art, and at the same time provide a further description of the creative improvements to the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com