Light-driven photocatalytic reactor and preparation method thereof

A photocatalytic reactor and light-driven technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems that photocatalysts are not easy to recycle, and achieve improved The effect of light energy utilization rate and photocatalytic efficiency, simple preparation method, and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

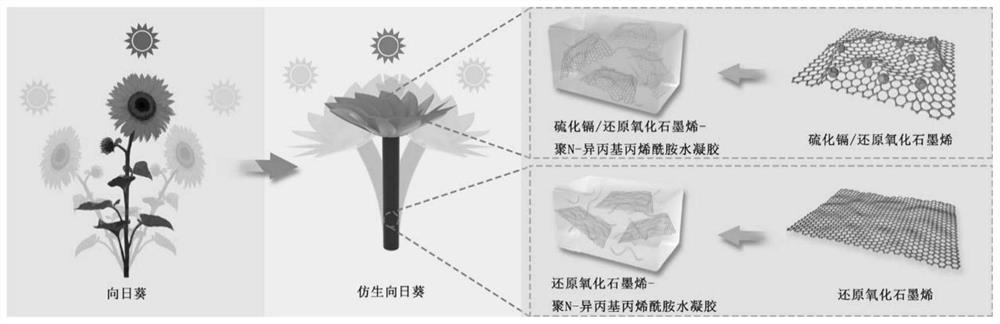

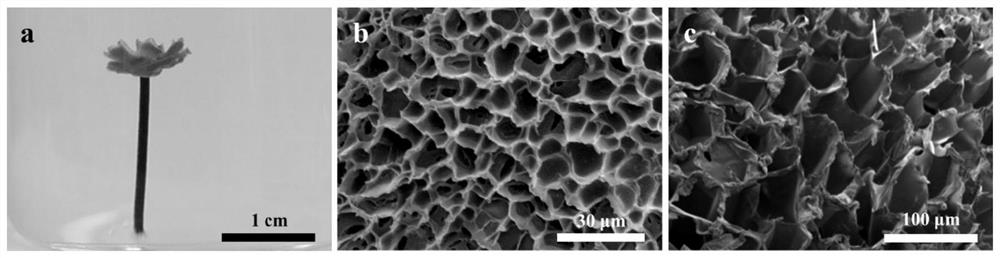

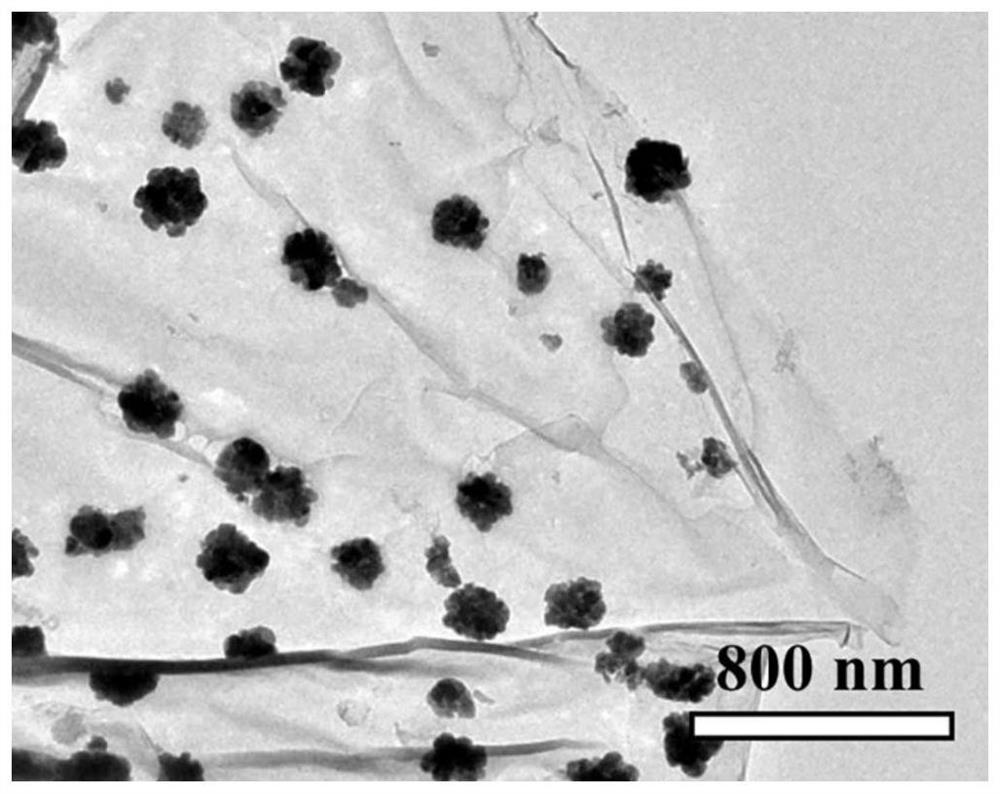

[0035] figure 1 It is a schematic diagram of a light-driven photocatalytic reactor. In this embodiment, cadmium sulfide / reduced graphene oxide is used as a photocatalyst as an example for the production of hydrogen peroxide, including the following steps:

[0036] (1) Take 3g of N-isopropylacrylamide monomer, stir and dissolve it in 30mL of a mixed solution of n-hexane and acetone with a volume ratio of 10:1 at 30°C, then cool at -10°C to precipitate crystals, pump After filtering and drying, the purified N-isopropylacrylamide monomer was obtained.

[0037] (2) Based on the total mass of 3g, weigh 1.2g of the N-isopropylacrylamide monomer obtained in step (1), 0.06g of N,N'-methylenebisacrylamide and 0.015g of 2-hydroxy - Dissolve 2-methylpropiophenone in 1.7145g of dimethyl sulfoxide, then add 0.0105g of graphene oxide into the mixed solution, and ultrasonically disperse to obtain a graphene oxide / N-isopropylacrylamide dispersion.

[0038] (3) Similarly, based on the total ...

Embodiment 2

[0049] The cadmium sulfide / reduced graphene oxide in Example 1 was changed to polymer carbon nitride, and the rest were the same as in Example 1, and the finally obtained light-driven photocatalytic reactor was designated as PPR-1. After testing, it is found that PPR-1 can stably follow the direction of oblique incident light as mentioned above, ensuring its maximum capture of light energy. In addition, the bending process of PPR-1 is reversible, and it can basically return to the upright state in about 30 minutes after being bent at 90°.

Embodiment 3

[0051] Change the concentration of cadmium sulfide / reduced graphene oxide in Example 1 to 2.5wt%, that is, the quality is changed to 0.075g, and the quality of dimethyl sulfoxide is changed to 1.65g accordingly, and all the other are the same as in Example 1. The driven photocatalytic reactor is denoted as PPR-2. After testing, it is found that PPR-2 can bend towards the light within about 50s under oblique light, and follow the direction of the incident light. Again, recovery occurs around 30 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com