Porous iron-manganese composite material for efficiently fixing and removing antimony pollution as well as preparation method and application of porous iron-manganese composite material

A manganese composite material, porous iron technology, applied in water pollutants, chemical instruments and methods, other chemical processes, etc., can solve the problem of not discussing the removal effect of iron-manganese composite materials on trivalent antimony, lack of porous structure, etc. To achieve the effect of favorable removal, broad application prospects and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

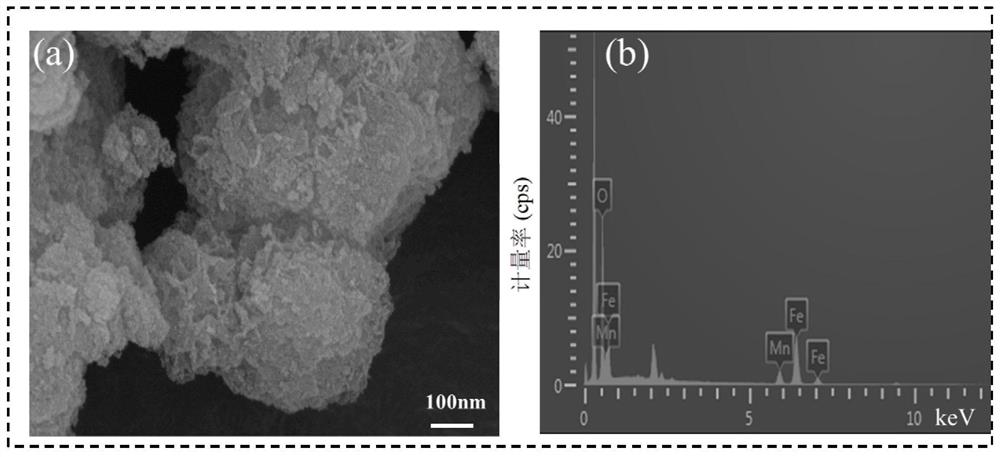

[0044] A method for preparing a porous iron-manganese composite material for efficiently fixing and removing antimony pollution, comprising the following steps:

[0045] (1) Accurately take by weighing 0.045mol potassium permanganate, 0.030mol manganese chloride and 0.075mol ferric chloride respectively, add respectively in 1000mL deionized water, obtain the potassium permanganate solution that concentration is 0.045mol / L after dissolving evenly, Concentration is the manganese chloride solution of 0.030mol / L and the ferric chloride solution that concentration is 0.075mol / L;

[0046] (2) After dropping the potassium permanganate solution into the manganese chloride solution at a rate of 1 mL / min, stir for 2 hours to obtain a suspension;

[0047] (3) Add ferric chloride solution to the suspension obtained in step (2) at a rate of 7.5 mL / min, and stir for 2 h to obtain a mixed solution;

[0048](4) Use ammonia water to adjust the pH of the mixed solution in step (3) to 7.5, age ...

Embodiment 2

[0051] A method for preparing a porous iron-manganese composite material for efficiently fixing and removing antimony pollution, comprising the following steps:

[0052] (1) Accurately take by weighing 0.015mol potassium permanganate, 0.010mol manganese chloride and 0.025mol ferric chloride respectively, add respectively in 1000mL deionized water, obtain the potassium permanganate solution that concentration is 0.015mol / L after dissolving evenly, Concentration is the manganese chloride solution of 0.010mol / L and the ferric chloride solution that concentration is 0.025mol / L;

[0053] (2) After dropping the potassium permanganate solution into the manganese chloride solution at a rate of 0.1 mL / min, stir for 1 hour to obtain a suspension;

[0054] (3) Add ferric chloride solution to the suspension obtained in step (2) at a rate of 5.0 mL / min, and stir for 1 h to obtain a mixed solution;

[0055] (4) Use ammonia water to adjust the pH of the mixed solution in step (3) to 7.0, ag...

Embodiment 3

[0058] A method for preparing a porous iron-manganese composite material for efficiently fixing and removing antimony pollution, comprising the following steps:

[0059] (1) Accurately take by weighing 0.090mol potassium permanganate, 0.060mol manganese chloride and 0.150mol ferric chloride respectively, add respectively into 1000mL deionized water, obtain the potassium permanganate solution that concentration is 0.090mol / L after dissolving evenly, Concentration is the manganese chloride solution of 0.060mol / L and the ferric chloride solution that concentration is 0.150mol / L;

[0060] (2) After the potassium permanganate solution is dripped into the manganese chloride solution at a rate of 5 mL / min, stir for 3 hours to obtain a suspension;

[0061] (3) Add ferric chloride solution to the suspension obtained in step (2) at a dropping rate of 10mL / min, and stir for 3h to obtain a mixed solution;

[0062] (4) Use ammonia water to adjust the pH of the mixed solution in step (3) t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com