Oxygen production and gas supply device and method for operating room and ICU

A gas supply device and operating room technology, applied in chemical instruments and methods, oxygen/ozone/oxide/hydroxide, oxygen preparation, etc., can solve problems such as inconvenient transportation, hidden safety hazards, restrictions, etc., and improve overall recovery rate, ensure impurity gas content, and meet the effect of long-term durable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

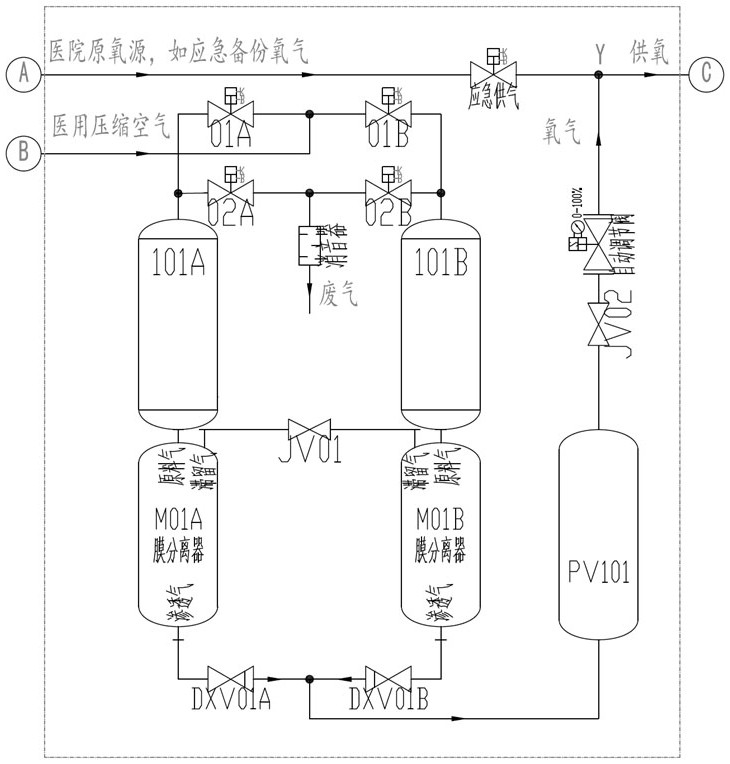

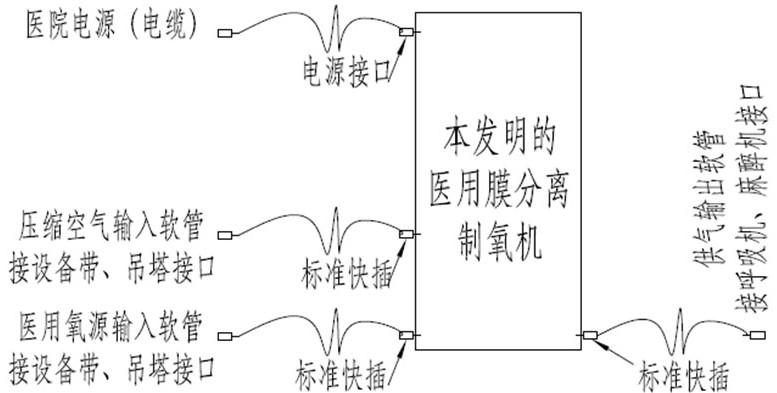

[0078] attached figure 2 A schematic diagram of the external connection of a medical membrane separation oxygen generator used in operating rooms and ICUs of the present invention, wherein, it includes as attached figure 1 An oxygen production and supply method for operating rooms and ICUs of the present invention and an oxygen production device for the coupling process of adsorption, separation, drying, purification and zeolite membrane separator described in the schematic flow diagram of the device, the system is freely attached figure 1 Compressed air inlet B (compressed air interface of hospital operating room pendant tower) is connected to 0.6MPa compressed air, and freely attached figure 1 The medical oxygen source inlet A (the oxygen supply interface of the hospital operating room pendant) is connected to the emergency backup oxygen source, which can be attached freely. figure 2 It can output medical oxygen ≧0.5MPa and purity ≧99.5% from the oxygen output port C, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com