Coconut shell-based mesoporous activated carbon, and preparation method and application thereof

A coconut shell-based, activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of chemical reagent activated carbon residues, high prices of titanium salts, and achieve pore size distribution The effect of wide range, simple preparation process and high mesoporosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

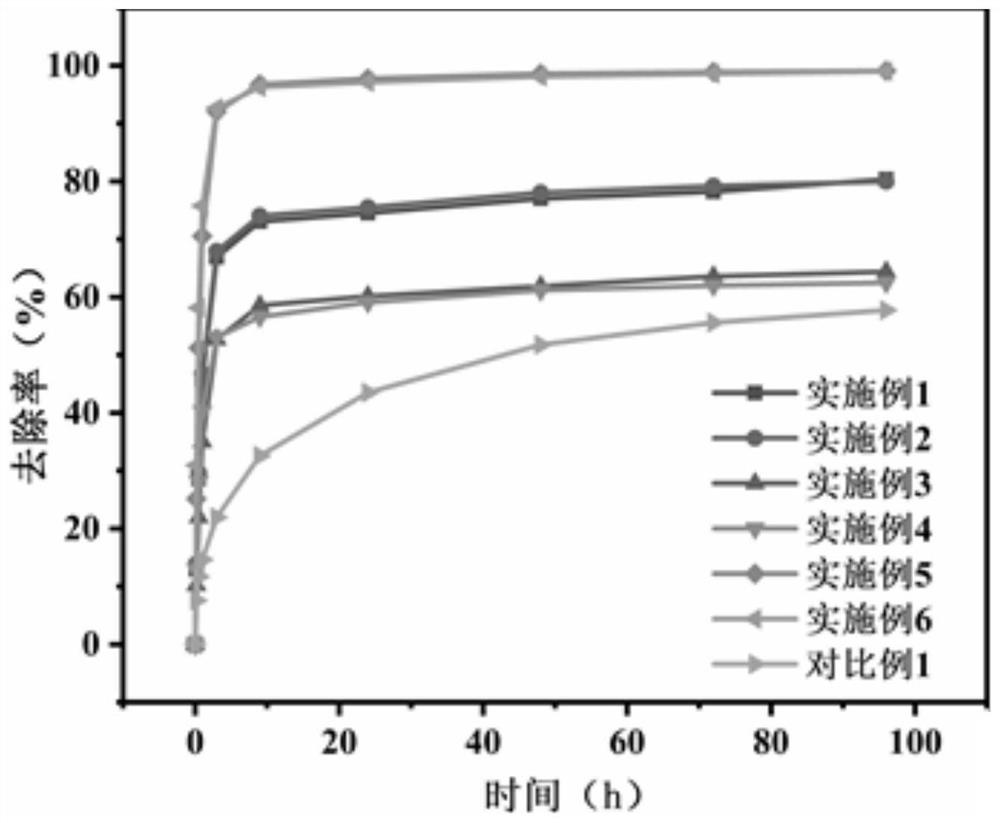

Examples

Embodiment 1

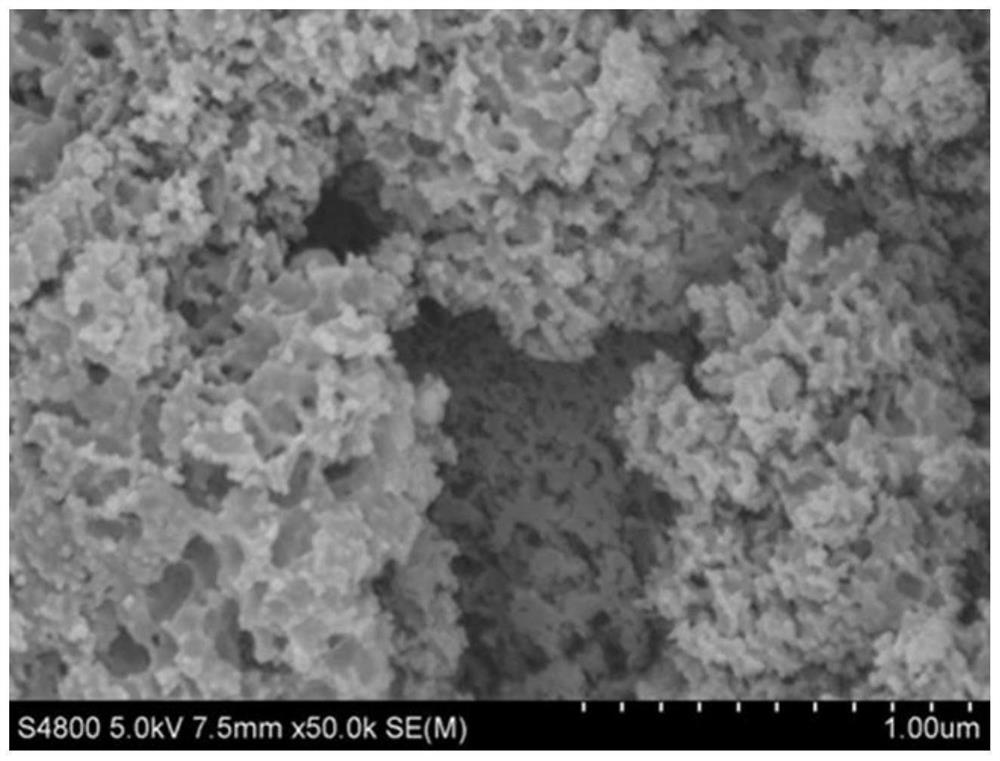

[0053] This embodiment provides a kind of coconut shell-based mesoporous activated carbon, and the preparation method of the coconut shell-based mesoporous activated carbon is as follows:

[0054] (1) Grind and sieve the coconut shell carbonized material, the particle size is 40-50 mesh, wash with deionized water, dry at 105°C for 6 hours and set aside;

[0055] (2) According to the mass ratio of iron to carbonized material of 0.25:100, weigh ferric nitrate of corresponding quality, add it to 40mL of water and ethanol mixture with a volume ratio of 4:1, after ferric nitrate is fully dissolved, add 10g coconut shell carbonized material, and impregnated with stirring at 400r / min for 24h, separated by suction filtration with neutral filter paper, and then dried at 105°C for use;

[0056] (3) Take 10g of the impregnated iron salt carbonized material obtained in step (2) and transfer it to a steel activation tube and place it in an activation furnace. After heating up to an activat...

Embodiment 2

[0062] This embodiment provides a kind of coconut shell-based mesoporous activated carbon, and the preparation method of the coconut shell-based mesoporous activated carbon is as follows:

[0063] (1) Grind and sieve the coconut shell carbonized material, the particle size is 50-60 mesh, wash with deionized water and dry at 110°C for 4 hours for use;

[0064] (2) According to the mass ratio of iron to carbonized material of 0.25:100, weigh the corresponding mass of ferric chloride, add it to 40mL of water and ethanol mixture with a volume ratio of 4:1, and after the ferric chloride is fully dissolved, add 10g of coconut shell carbonized material, stirred and impregnated for 20h under the condition of 450r / min, separated by suction filtration with neutral filter paper, dried at 105°C for use;

[0065] (3) Take 10g of the impregnated iron salt carbonized material obtained in step (2) and transfer it to a steel activation tube and place it in an activation furnace. After heating ...

Embodiment 3

[0071] The only difference between this embodiment and embodiment 1 is that the mass ratio of iron to carbonized material in step (2) is 0.1:100, and other conditions and parameters are exactly the same as in embodiment 1.

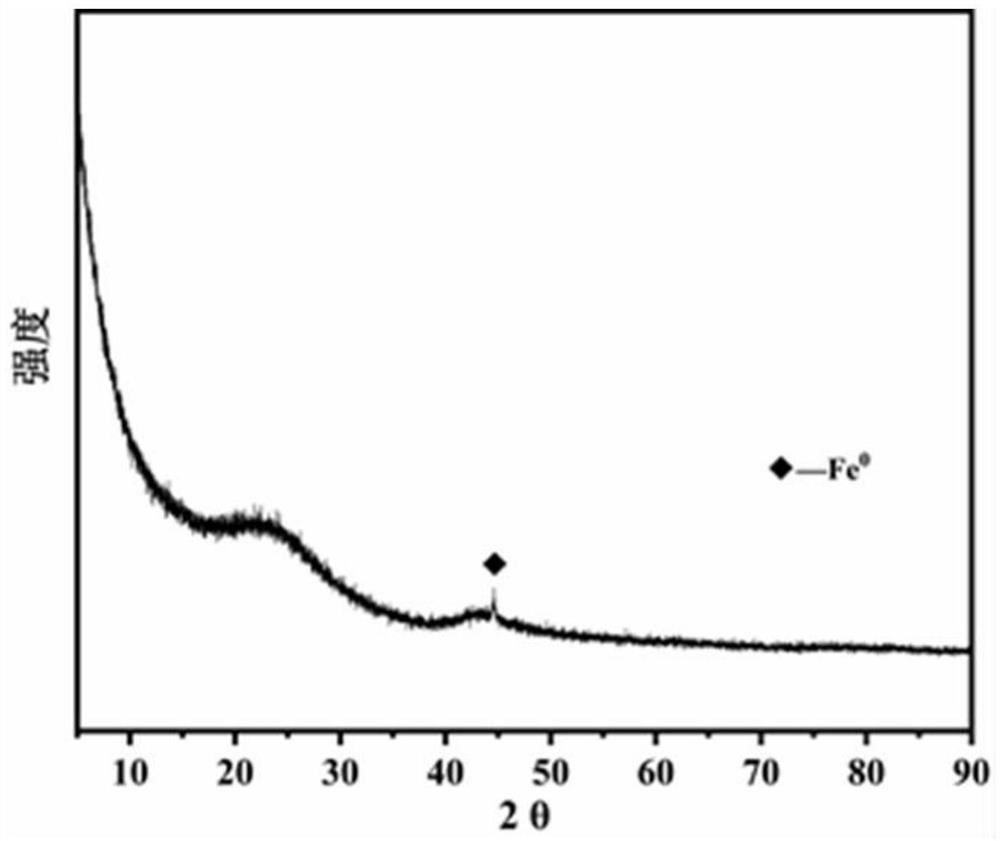

[0072] Through the nitrogen adsorption and desorption isotherm test, the specific surface area of the sample prepared in this embodiment is calculated by using the BET and BJH methods to be 833.69m 2 / g, the total pore volume is 0.86cm 3 / g, mesoporosity is 72.78%, BJH average pore diameter is 10.08nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com