Nanocrystalline A4B2O9 type niobate ceramic prepared through ultralow-temperature sintering, and preparation method thereof

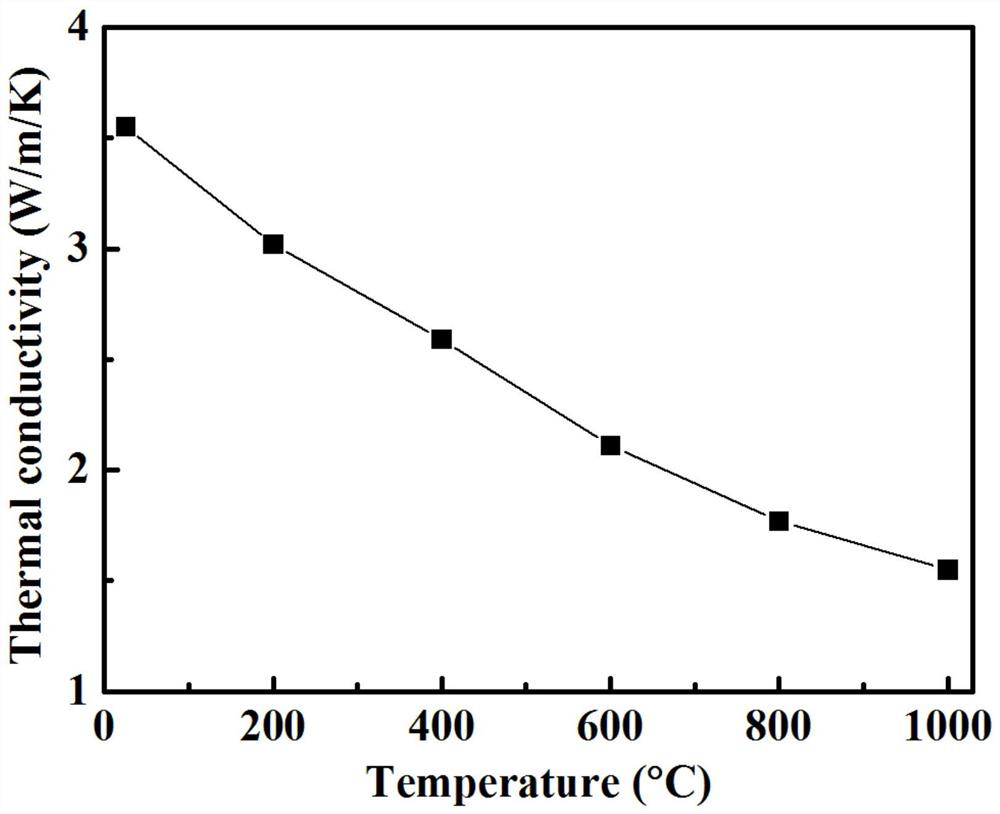

An A4B2O9 and niobate technology is applied in the field of ultra-low temperature sintering to prepare nanocrystalline A4B2O9 type niobate ceramics, which can solve the problems of high cost, high prices of tantalate and rare earth elements, reduce thermal conductivity, shorten sintering time, Avoid high porosity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

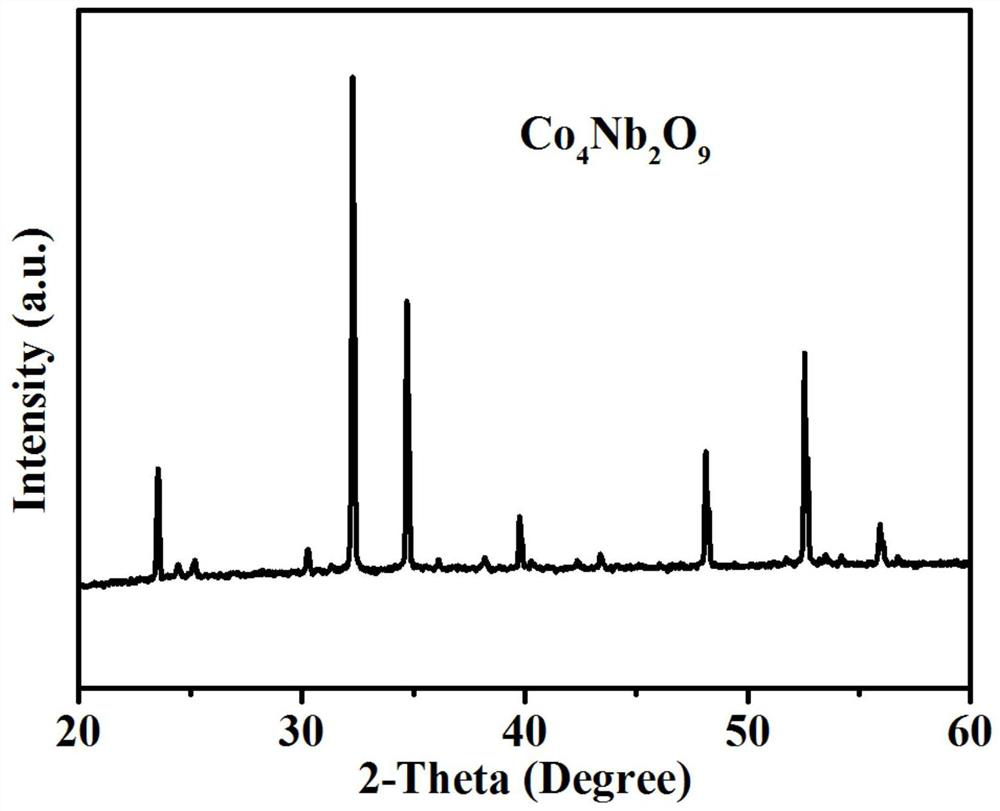

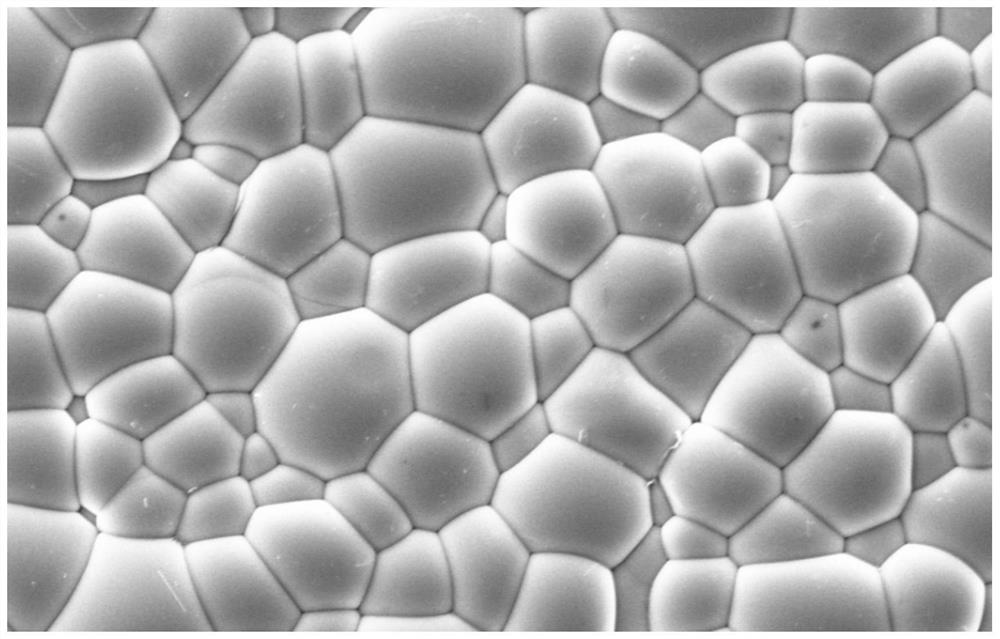

[0042] A nanocrystalline A4B2O9 type niobate ceramic prepared by ultra-low temperature sintering, the structural formula of the ceramic is Co 4 Nb 2 o 9 . Its preparation method comprises the following steps:

[0043] step one,

[0044] CoCO 3 , niobium oxalate respectively at 450-950°C for 1-1.5h, and through thermal decomposition, highly reactive CoO and Nb are obtained 2 o 5 . In this embodiment, the heat preservation temperature is preferably 720° C., and the heat preservation time is preferably 1 h.

[0045] step two,

[0046] CoO, Nb 2 o 5 The powder and alcohol with a purity of 99.99% are put into a high-energy ball mill for grinding, the weight ratio of powder and alcohol is 1:6-10, the speed of grinding is 2200-3500rpm, and the grinding time is 11-24h. After grinding, the powder is taken out, kept at 65-80°C for 6-10 hours, and dried to form a highly reactive powder mixture with nanometer size. In this example, the weight ratio of powder to alcohol is 1:8,...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is that the structural formula of A4B2O9 type niobate ceramics in this embodiment is Ni 4 Nb 2 o 9 , its preparation method is consistent with Example 1.

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 1 is that the structural formula of the A4B2O9 type niobate ceramics in this embodiment is Mg 4 Nb 2 o 9 , its preparation method is consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com