Method for catalytically synthesizing sucrose ester by using amorphous sucrase

An amorphous and sucrose ester technology, which is applied in the field of catalyzing and synthesizing sucrose esters by using amorphous sucrase, can solve the problems of increasing the difficulty of separation and purification of products, limited application of sucrose esters, etc., and achieves improved solubility, dissolution rate, and safety. The effect of improving and high enzymatic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First add 1.25g sodium caseinate to 500mL pure water, stir slowly at 50°C until completely dissolved, then add 123.75g sucrose, and dissolve completely to prepare a sucrose-sodium caseinate mixed solution. Add 0.3% Tween 20 and 0.3% methanol respectively to five parts of the above mixed solutions, mix well and carry out spray drying (conditions are: the water evaporation rate is 2kg / h, the inlet temperature is 170°C, and the outlet temperature is 70°C ), after spray-drying, dry in a vacuum oven at 50-60° C. for 5 hours to obtain amorphous sucrose with a yield of 96%.

Embodiment 2

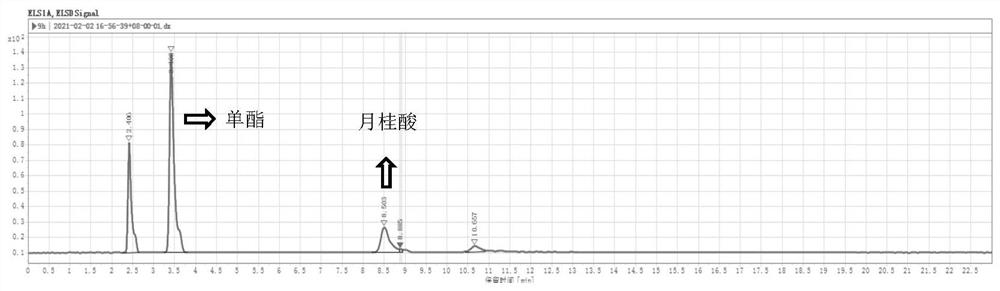

[0032] In a 50mL round bottom flask, add 0.3g amorphous sucrose, 1.81mmol (470μL) vinyl laurate and 15mL tert-amyl alcohol, and add 1% sodium caseinate, 0.3% methanol and 0.2% Tween 20 at the same time, at 60 ℃ in a water bath and stir for 1h, then add 0.4g Molecular sieves were reacted in a water bath at 60°C for 12 hours. After the reaction was finished, it was detected by HPLC that no sucrose monoester was formed.

[0033] This result proves that other components in the above sucrose solution have no catalytic activity for sucrose ester synthesis.

Embodiment 3

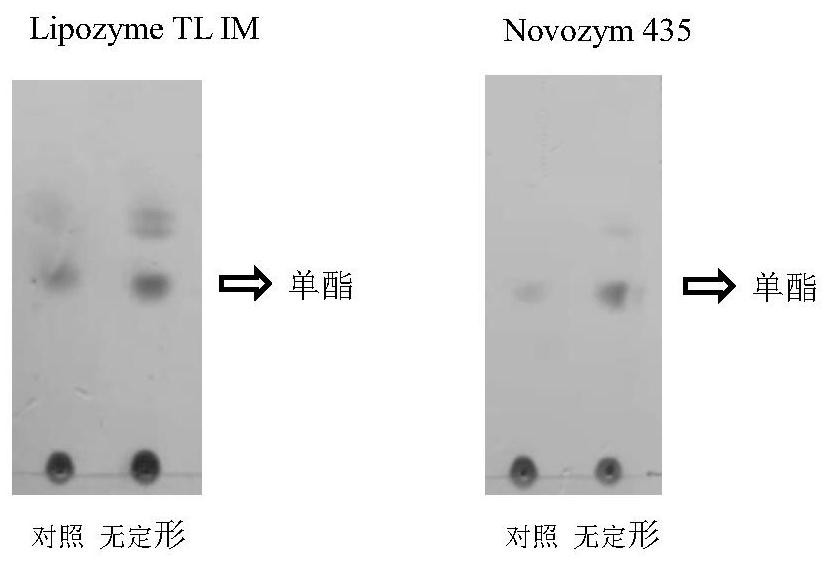

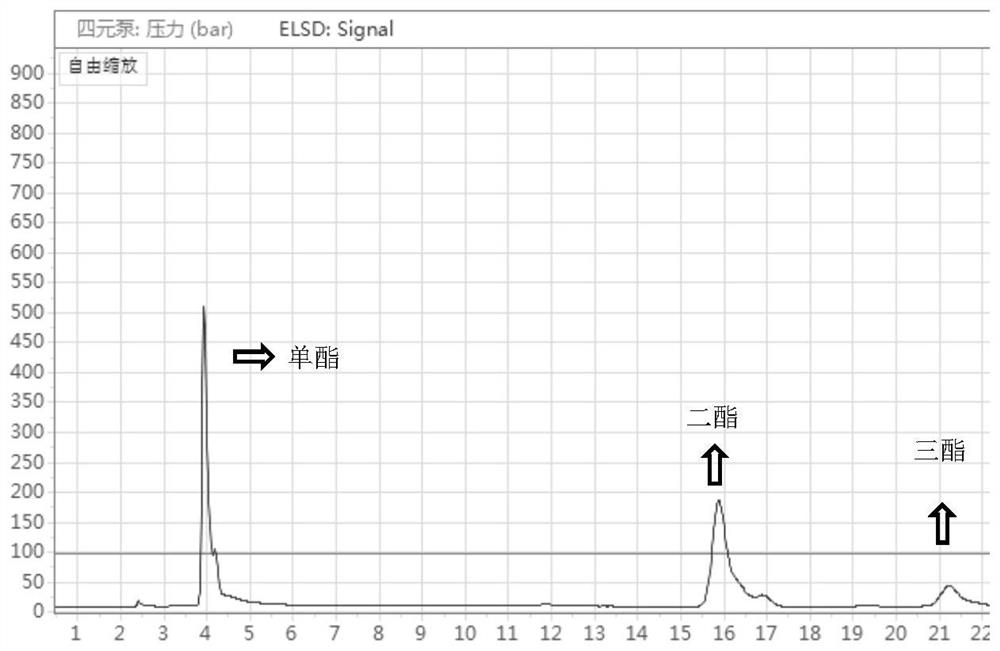

[0035] Add Lipozyme TL IM, Novozym 435, Candida rugosa lipase, Pseudomonas fluorescens lipase, A. 15mL tert-amyl alcohol, 1.81mmol (470μL) vinyl laurate, 0.4g crystalline sucrose and 0.4g Molecular sieves were reacted in a water bath at 60°C for 12 hours. After the reaction, the concentrations of sucrose monoesters measured by HPLC were 8.2, 3.5, 2.9, 1.1, and 0.5 g / L, respectively. The results showed that the yield of sucrose monoesters was the highest when Lipozyme TL IM was used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com