Reburning denitration biogas treatment system of garbage incineration grate furnace

A waste incinerator and biogas technology, applied in incinerators, non-combustible liquid/gas transportation, combustion methods, etc., can solve the problems of increased NOx emission concentration, energy waste, and temperature rise, and reduce the amount of ammonia injection , reduce the amount of ammonia injection, improve the effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

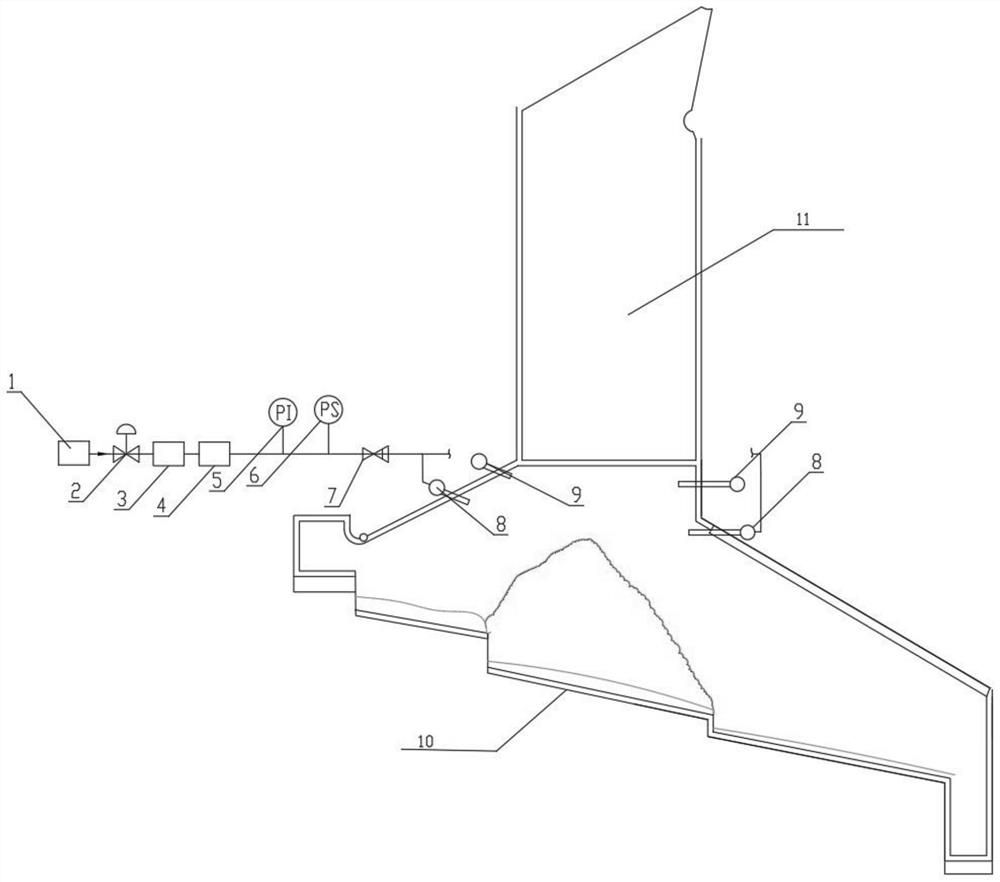

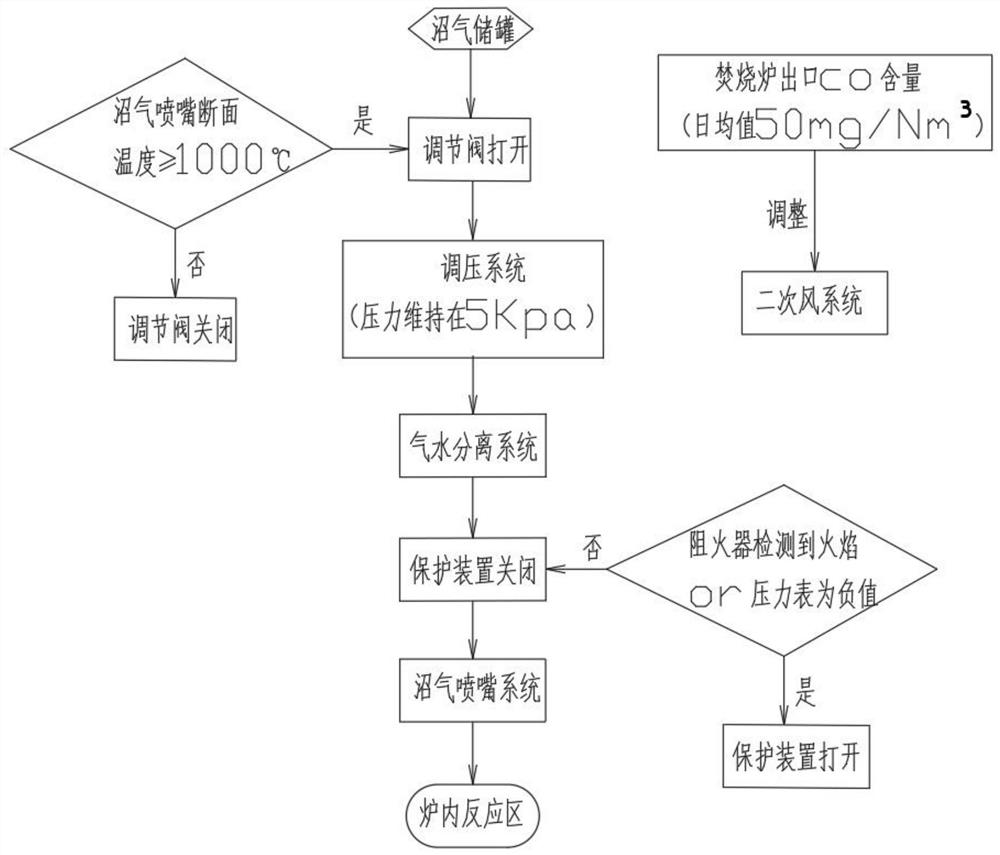

[0018] Such as figure 1 As shown, the incinerator is a stepped furnace (10) with inclination, and the front and rear arch and side walls, the flue (11) is composed, and the biogas return nozzle (8) and the secondary wind nozzle (9) are arranged before and after arch. Location, the biogas return nozzle (8) is disposed at the upper and rear arches, and the front arch region is disposed at a 20 ° arrangement, and the rear arch region is disposed. Biogas take the anaerobic fermentation system, output from the biogas storage tank (1), the flow rate is controlled by the pneumatic regulator (2), the pressure regulating system (3) is to maintain system pressure, enhance gas mixed disturbance, improve mixing If the gas stop time is provided, the gas-water separation system (4) can separate moisture in the biogas, pressure gauge (5), pressure switch (6) and fire detector (7) prevent flue gas or flame from entering the biogas pipe system. When the biogas nozzle section temperature reaches 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com