High-voltage cable capable of regulating and controlling breakdown field strength

A technology for high-voltage cables and breakdown field strength, which is applied in the direction of power cables, power cables with shielding layers/conductive layers, insulated cables, etc., and can solve problems such as lowering the operating level of cables, limited improvement range, and long industrialization cycle. Achieve the effect of avoiding PTC effect, increasing voltage level and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

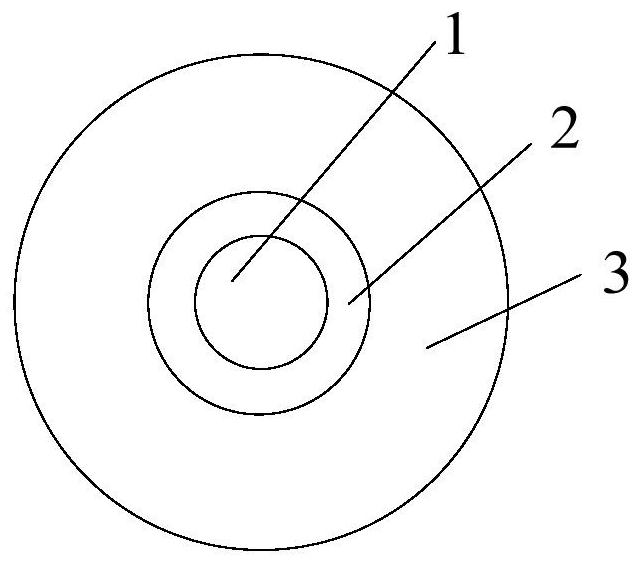

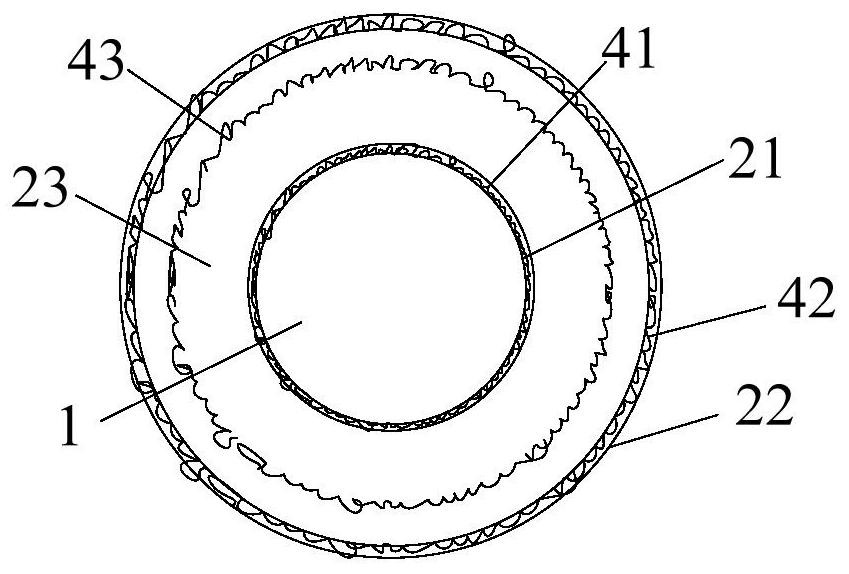

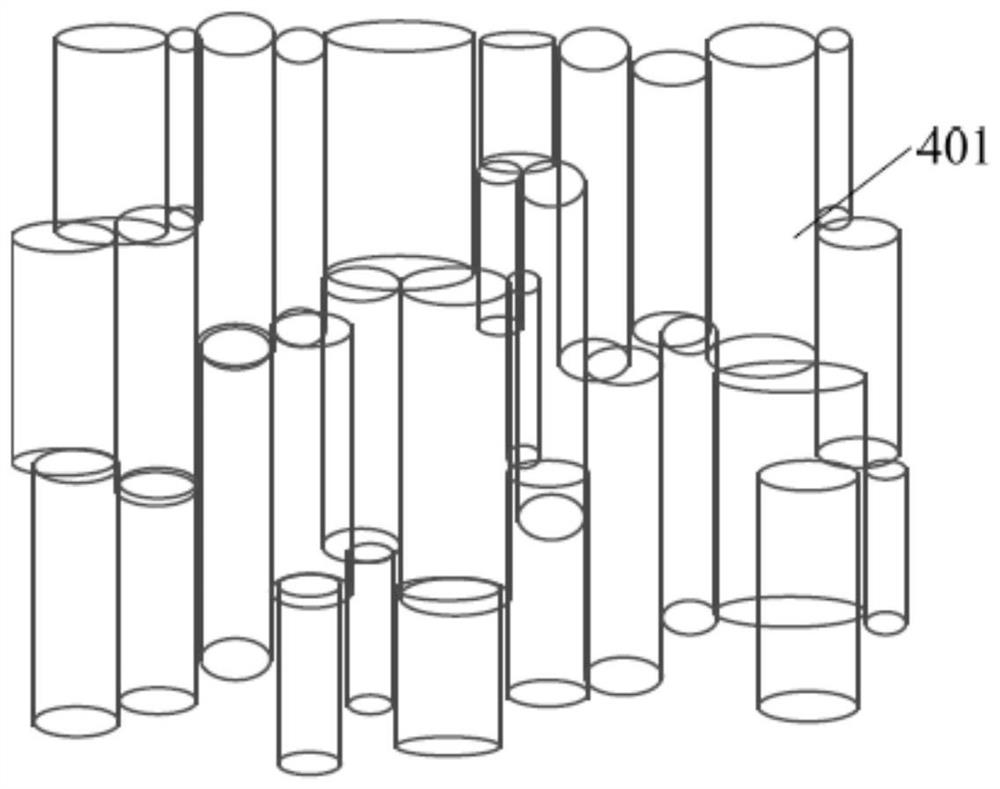

[0054] Such as figure 2 As shown, this embodiment provides a high-voltage cable with adjustable breakdown field strength, which includes a core 1 and an insulating layer 2. There is no inner semi-conductive shielding layer between the core 1 and the insulating layer 2, and the insulating layer 2 is divided into The inner boundary area 21 opposite to the wire core 1, the outer area, and the inner area 23 between the two parts, the inner boundary area has a first nanoporous structure 41, and the nanopores 401 in the first nanoporous structure 41 The extension direction is perpendicular to the cable extension direction. The outer region 22 of the insulating layer has a second nanoporous structure 42, and the extending direction of the nanoholes 401 in the second nanoporous structure 42 is perpendicular to the extending direction of the cable. The inner region 23 of the insulating layer has a third nanohole structure 43, and the extension direction of the nanoholes 401 in the th...

Embodiment 2

[0056] Compared with Embodiment 1, the high-voltage cable with adjustable breakdown field strength provided by this embodiment is different in that the first nanoporous structure 41, the second nanoporous structure 42 and the third nanoporous structure 43 are arranged in layers , and the nanoporous structure is composed of multi-layer nanoporous structures, and each layer of nanoporous structures is bonded to each other; the axial direction of the nanoholes 401 in the first nanoporous structure 41 is approximately perpendicular to the outer surface of the wire core 1, and the second nanoporous structure The axial direction of the nanoholes 401 in the hole structure 42 is approximately perpendicular to the outer surface of the insulating layer 2 ; and the nanoholes 401 between the nanohole structures of each layer are arranged in a dislocation manner.

[0057] Such as Figure 4 As shown, it is a schematic structural diagram of the insulating layer of the high-voltage cable with...

Embodiment 3

[0059] The structure of the high-voltage cable provided in this embodiment is the same as in Embodiment 2, the difference is that the medium contained in the nanopores 401 of the first nanoporous structure 41, the second nanoporous structure 42 and the third nanoporous structure 43 is mineral oil , the diameters of the nanopores 401 are inconsistent, and the maximum value of the diameter d1 of the nanopores 401 is 300 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com