Gradient high-nickel single-crystal ternary material, preparation method thereof and battery using same

A high-nickel ternary material, ternary material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low compaction density, poor battery cycle performance and safety performance, easy to break, etc., to achieve a stable surface structure, reducing the amount of residual alkali, and improving the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

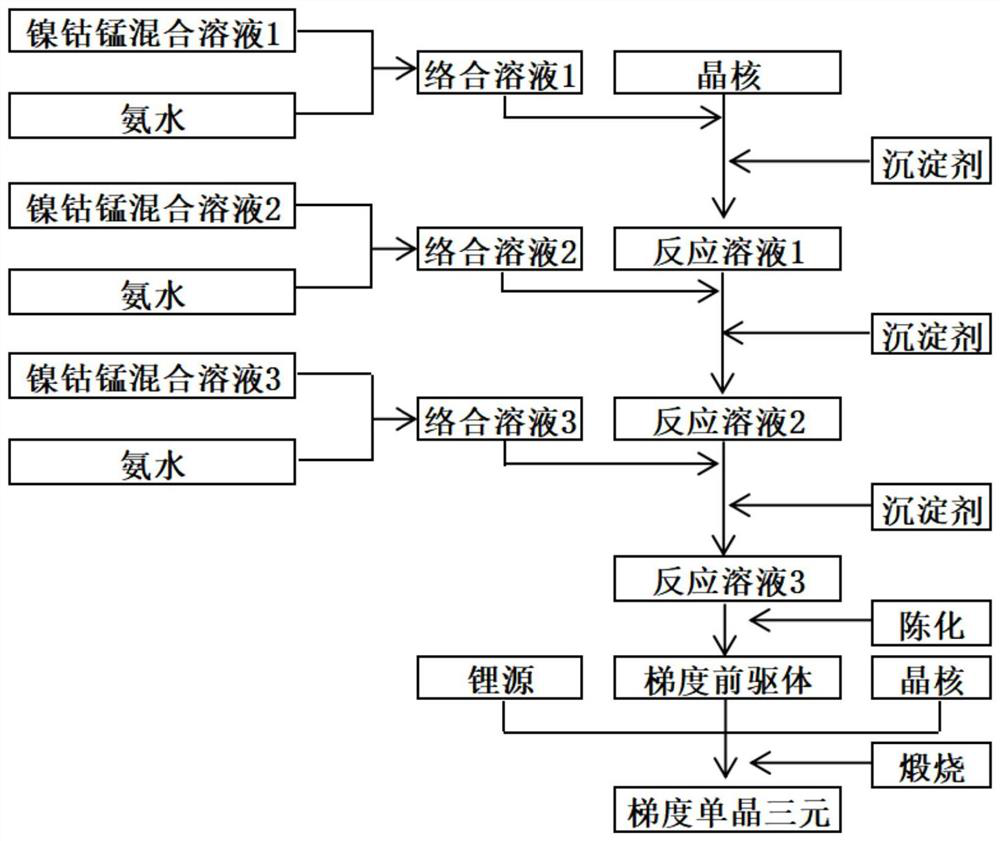

[0021] The invention provides a method for preparing a gradient high-nickel single crystal ternary material, wherein the preparation method comprises:

[0022] (1) Nanoscale high-nickel ternary material particles are used as crystal nuclei;

[0023] (2) The crystal nucleus and the first nickel-cobalt-manganese solution carry out the first co-precipitation reaction, and the second nickel-cobalt-manganese solution is added to the solution completed in the first co-precipitation reaction to carry out the second co-precipitation reaction, according to this method Co-precipitation reactions are carried out n times; the nickel content in the first nickel-cobalt-manganese solution to the nth nickel-cobalt-manganese solution decreases in a gradient, and the manganese content increases in a gradient;

[0024] (3) Mixing the product of the nth co-precipitation reaction, the lithium source and the crystal nucleus, and calcining in an oxygen-containing atmosphere;

[0025] Among them, n≥...

Embodiment 1

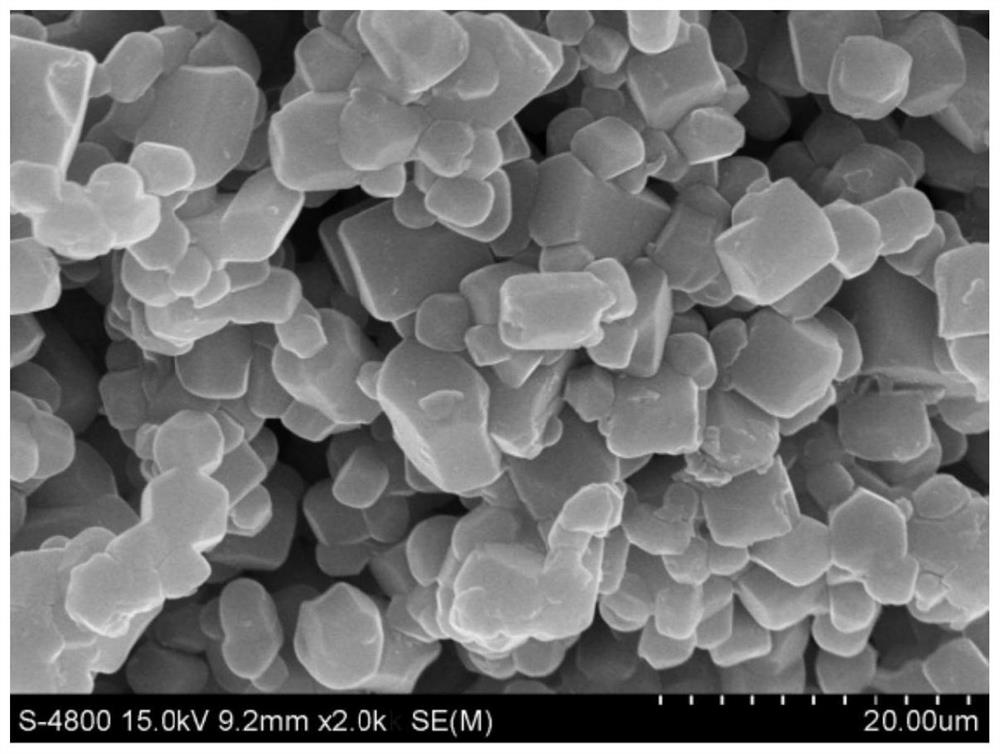

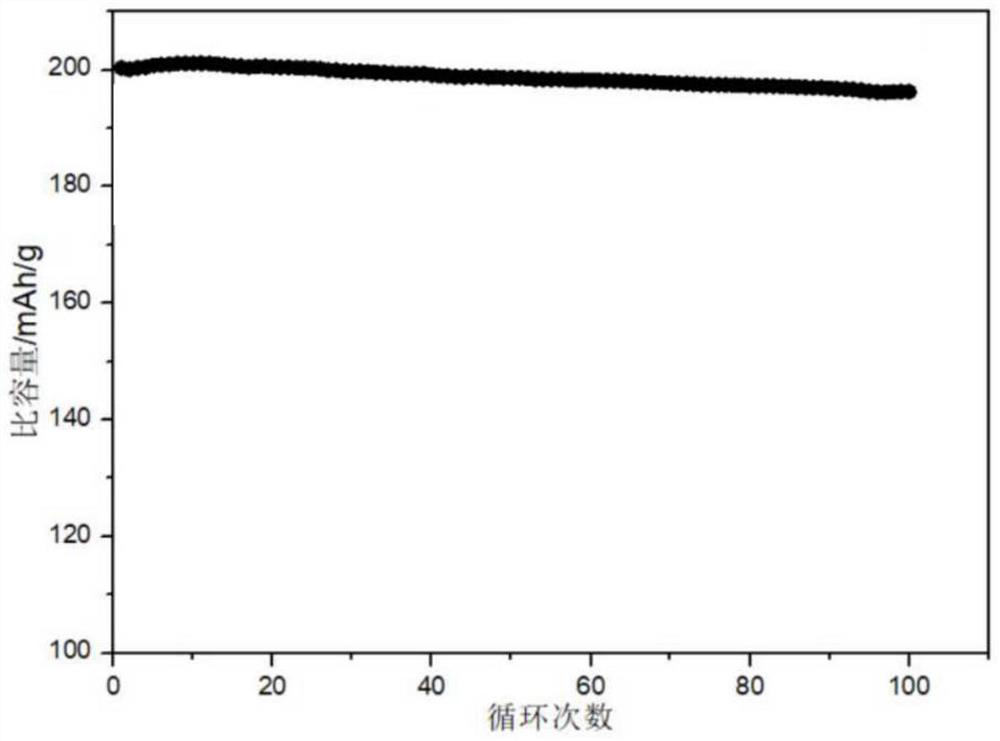

[0062] This example is used to illustrate the gradient high-nickel single crystal ternary material of the present invention and its preparation method. Its preparation process is as figure 1 As shown, the specific steps include:

[0063] (1) Put the commercially available high-nickel 811 ternary material into a ball mill, control the ball-to-material ratio to 1:15, rotate at 1500rpm, and mill for 3 hours to obtain high-nickel ternary material particles with an average particle diameter of 150nm. Nuclear backup;

[0064] (2) Based on the total molar weight of metal elements, in terms of elements, the molar ratio of nickel, cobalt and manganese is 9:0.5:0.5, respectively weigh nickel sulfate, cobalt sulfate and manganese sulfate and add them to deionized water to prepare The total metal element concentration that forms nickel-cobalt-manganese is the first nickel-cobalt-manganese solution containing 2mol / L, and 2mol / L ammoniacal liquor is added dropwise in the first nickel-coba...

Embodiment 2

[0075] This example is used to illustrate the gradient high-nickel single crystal ternary material of the present invention and its preparation method.

[0076] (1) Put the commercially available high-nickel 811 ternary material into a ball mill, control the ball-to-material ratio to 1:20, and the rotating speed is 2000rpm, and ball mill for 2 hours to obtain high-nickel ternary material particles with an average particle diameter of 100nm. Nuclear backup;

[0077] (2) Based on the total molar weight of metal elements, in terms of elements, the molar ratio of nickel, cobalt and manganese is 9:0.5:0.5, respectively weigh nickel acetate, cobalt acetate and manganese acetate and add them to deionized water The total metal element concentration that forms nickel-cobalt-manganese is the first nickel-cobalt-manganese solution containing 1mol / L, and 2mol / L ammoniacal liquor is added dropwise in the first nickel-cobalt-manganese solution, so that NH 3 ·H2 The molar ratio of O to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com