A kind of high-light-transmitting heat-insulating ultraviolet-shielding polyester film and preparation method thereof

A technology of polyester film and ultraviolet rays, applied in the field of polyester film, can solve the problems of coating production method pollution, high coating cost, and large loss, and achieve low production cost, no environmental pollution, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

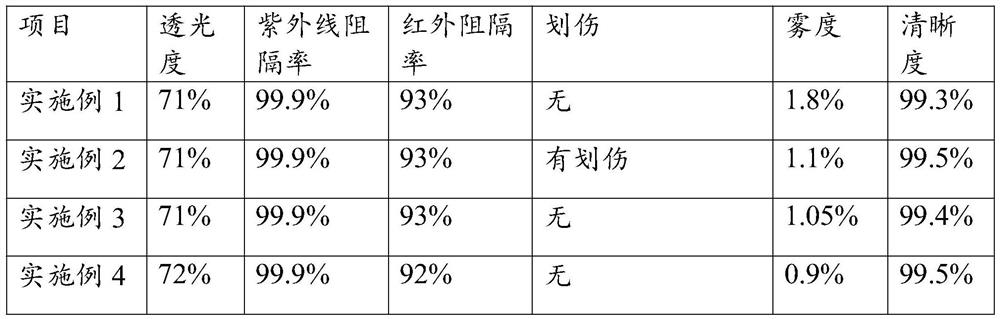

Examples

Embodiment 1

[0046] (1) Weigh the materials of the upper surface layer and the lower surface layer: 30% of polyester chips, 70% of optical grade opening agent;

[0047] The middle layer is weighed: 65% of polyester chips, 25% of thermal insulation masterbatch, and 10% of ultraviolet absorber.

[0048] (2) After the weighed upper surface layer, lower surface layer and intermediate layer materials are respectively sent to different silos for mixing, then sent to the crystallizer to crystallize the particles at 140°C, and the crystallized raw materials enter the drying tower at 120°C drying to a moisture content of less than 40 ppm to obtain pretreated raw materials;

[0049] (3) Film making

[0050] ①Extrusion: The pretreated upper surface layer, lower surface layer and intermediate layer materials are melted and filtered in three extruders respectively, and then enter the T-die head. The material flows out evenly through the automatically adjustable die lip and is a sheet-like melt; the e...

Embodiment 2

[0055] (1) The materials of the upper surface layer and the lower surface layer are weighed: 65% of polyester chips, 35% of optical grade opening agent;

[0056] The middle layer is weighed: 65% of polyester chips, 25% of thermal insulation masterbatch, and 10% of ultraviolet absorber.

[0057] (2) After the weighed upper surface layer, lower surface layer and intermediate layer materials are respectively sent to different silos for mixing, then sent to the crystallizer to crystallize the particles at 170°C, and the crystallized raw materials enter the drying tower at 150°C drying to a moisture content of less than 40 ppm to obtain pretreated raw materials;

[0058] (3) Film making

[0059] ①Extrusion: The pretreated upper surface layer, lower surface layer and intermediate layer materials are melted and filtered in three extruders respectively, and then enter the T-die head. The material flows out uniformly through the automatically adjustable die lip and is a sheet-like me...

Embodiment 3

[0064] (1) Weigh the materials of the upper surface layer and the lower surface layer: 15% of polyester chips, 30% of optical grade opening agent, 50% of thermal insulation masterbatch, and 5% of ultraviolet absorber;

[0065] The middle layer is weighed: 70% of polyester chips, 22% of thermal insulation masterbatch, and 8% of ultraviolet absorber.

[0066] (2) After the weighed upper surface layer, lower surface layer and intermediate layer materials are respectively sent to different silos for mixing, then sent to the crystallizer to crystallize the particles at 150°C, and the crystallized raw materials enter the drying tower at 170°C drying to a moisture content of less than 40 ppm to obtain pretreated raw materials;

[0067] (3) Film making

[0068] ①Extrusion: The pretreated upper surface layer, lower surface layer and intermediate layer materials are melted and filtered in three extruders respectively, and then enter the T-die head. The material flows out evenly throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com