Controllable growth method of electron beam induced carbon-based nanostructure based on needle tip enhancement

An electron beam-induced, carbon-based nanotechnology, which is applied in the manufacture of nanostructures, the formation of specific nanostructures, nanocarbons, etc., can solve the problems of slow growth rate and limited application potential, achieve rapid growth, enhance local electric field strength, and accelerate The effect of growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

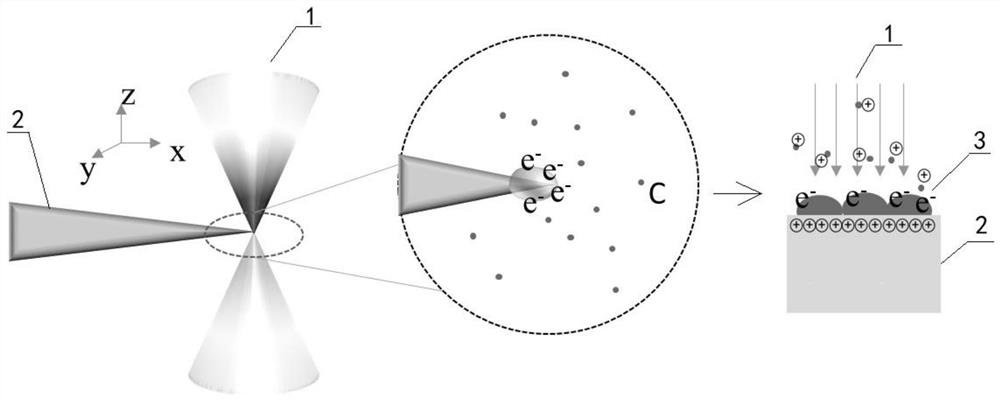

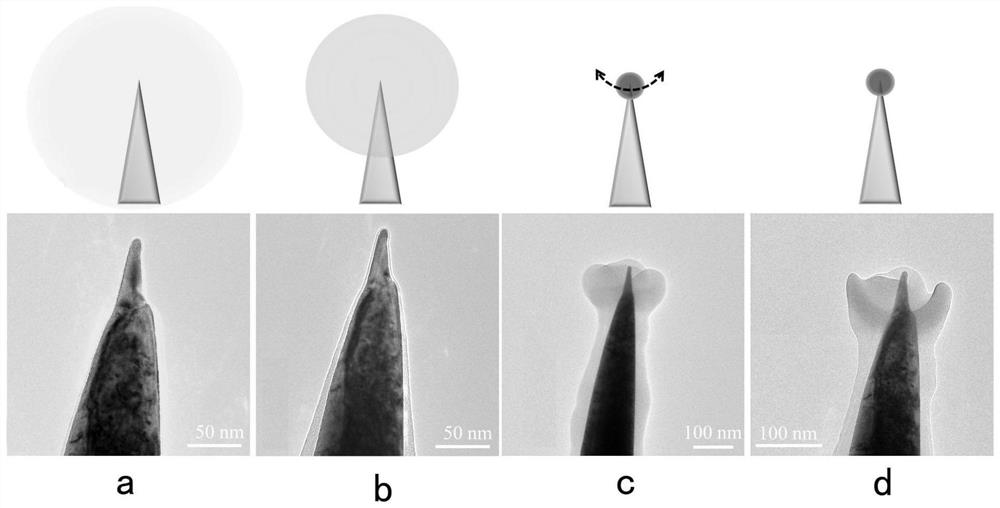

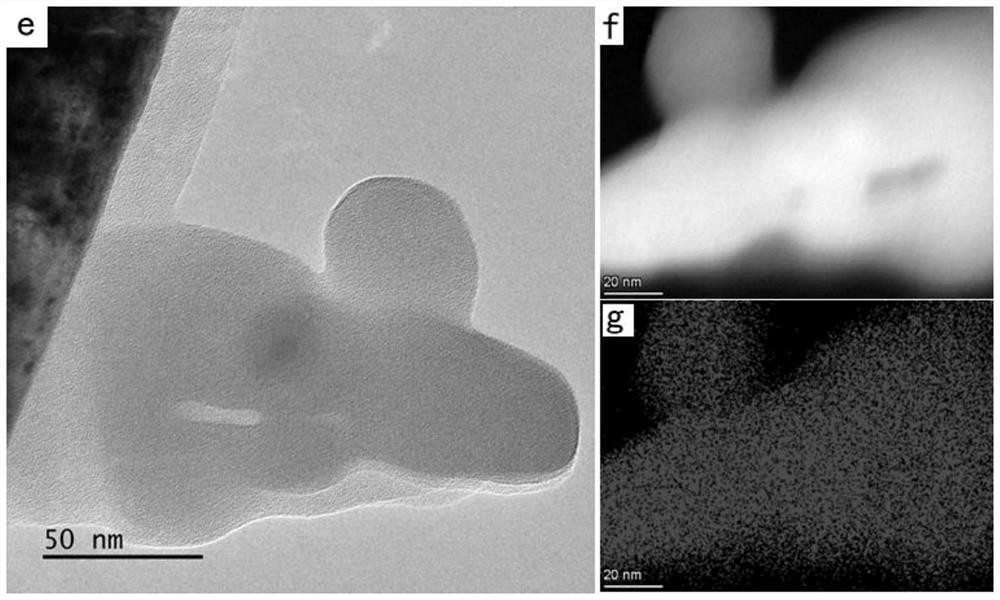

[0038] Example 1 Controllable growth method of electron beam-induced carbon-based nanostructures based on tip enhancement

[0039] A metal tungsten wire with a diameter of 0.5mm is sequentially passed through KOH-HClO 4 Metal tungsten nano-tips are processed by methanol solution corrosion and FIB ion beam etching. The radius of curvature of the metal tungsten nano-tips is 10nm; the metal tungsten nano-tips are used as the substrate and loaded on the sample rod of the transmission electron microscope; the transmission electron microscope is operated to gather electrons The beam spot irradiates the surface of the nano-tip to induce the growth of the three-dimensional nanostructure of amorphous carbon on the surface of the nano-tip; move the electron beam spot according to the designed model pattern for direct writing, and the amorphous carbon three-dimensional nanostructure on the surface of the nano-tip follows the growth of the electron beam spot Move and grow, so as to realiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com