Reforming hydrogen production and catalytic combustion integrated device with variable catalyst particle arrangement

A catalyst particle and catalytic combustion technology, applied in the direction of combustion type, combustion method, hydrogen, etc., can solve the problems that the fuel utilization rate cannot reach 100%, the catalyst filling form is single, and the integration of the reformer is low, so as to improve the energy utilization rate , compact structure, enhanced contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

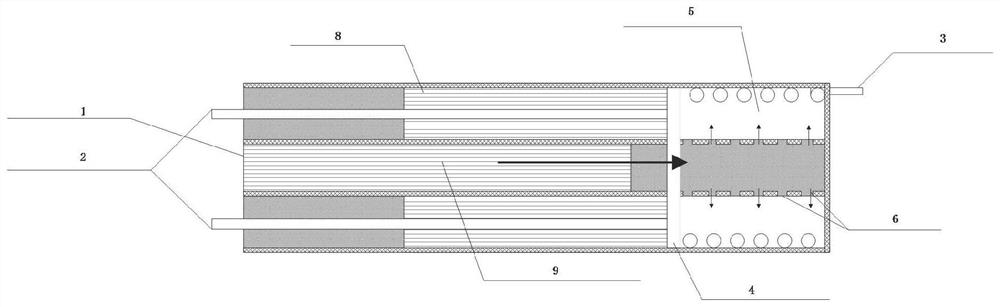

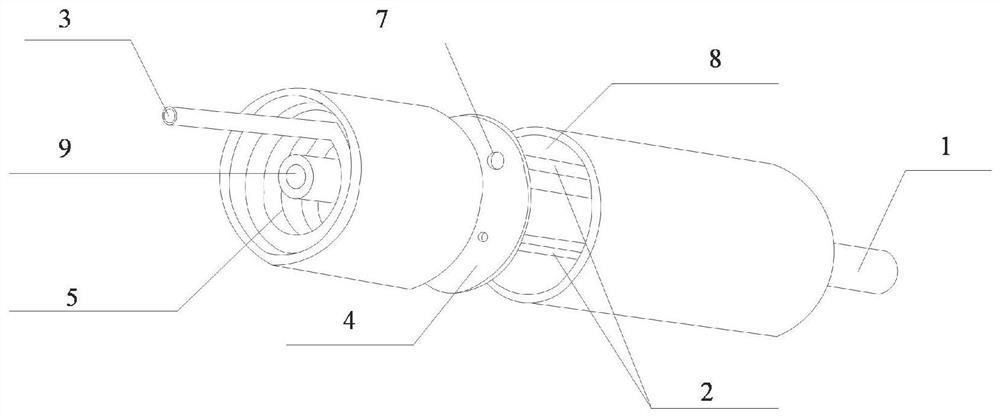

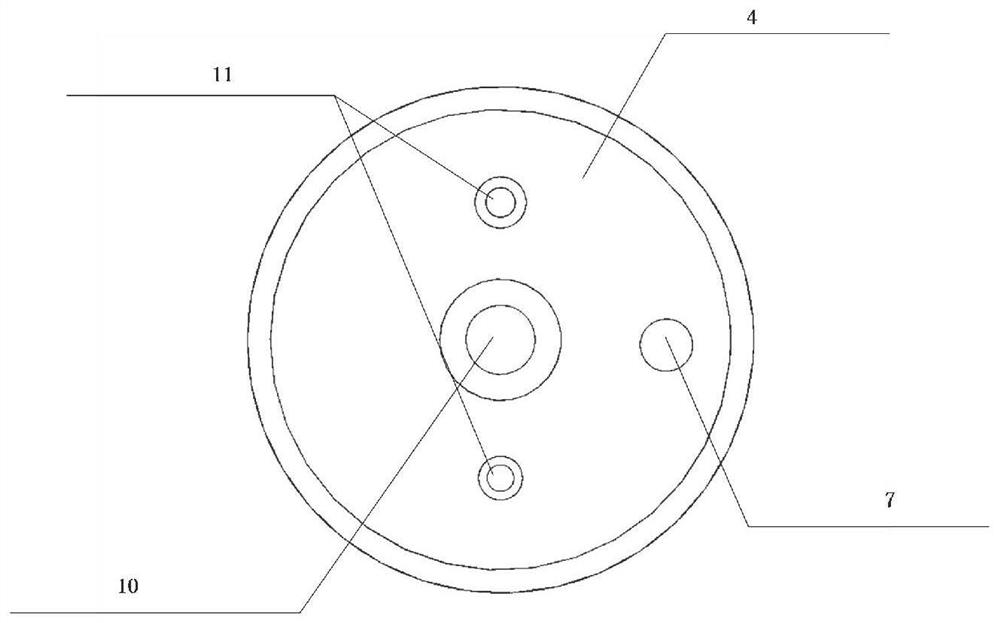

[0031] Specific implementation mode one: see Figure 1-5 This embodiment will be described. The reforming hydrogen production and catalytic combustion integrated device with variable catalyst particle arrangement described in this embodiment, the device is in the form of a sleeve, and catalytic combustion and catalytic reforming reactions occur simultaneously, including catalytic combustion gas inlet 1, catalytic combustion exhaust gas Outlet pipe 2, reformed gas inlet 3, preheating chamber 5, tail gas micropore 6, reformed gas connecting hole 7, reforming chamber 8 and catalytic combustion chamber 9, the catalytic combustion chamber 9 runs through the reforming chamber 8 and the preheating chamber hot chamber 5,

[0032] One end of the catalytic combustion chamber 9 is provided with a catalytic combustion gas inlet 1, and the tail gas of the catalytic combustion enters the catalytic combustion chamber 9 from the catalytic combustion gas inlet 1. At the end of the catalytic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com