Concrete curing agent and preparation method thereof

A technology of concrete curing agent and stabilizer, which is applied in the field of concrete curing agent and its preparation, can solve the problems of poor water retention and decreased water retention effect, and achieve the effects of improving water retention rate, good water retention effect and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

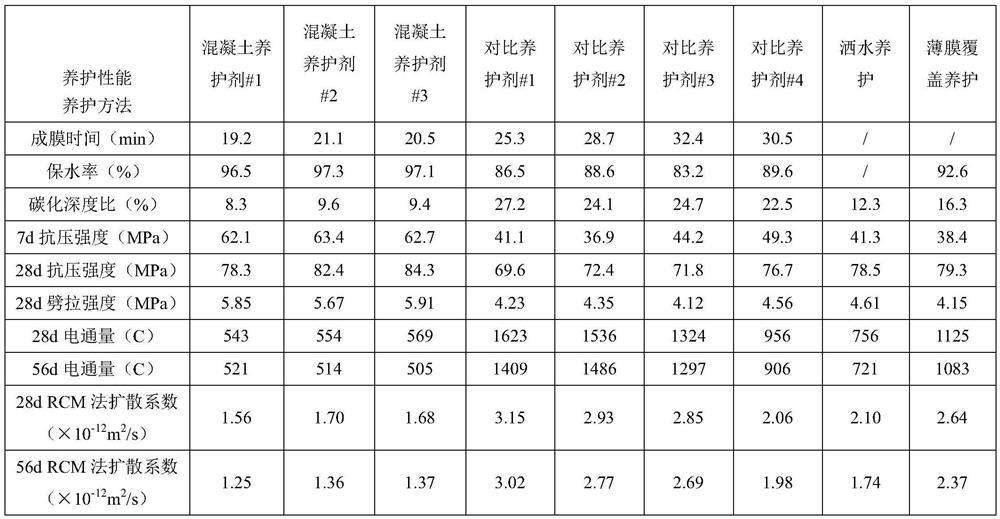

Examples

Embodiment 1

[0052] 100 parts by weight of β carboxyethyl acrylate, 56 parts by weight of dodecylvinyl ether, 78 parts by weight N, N-dimethyl methacrylate, 112 parts by weight of 2-methacrylate methoxyethyl ethyl escency The monomer and 1000 parts by weight of water were mixed; 140 ° C, stirring under stirring conditions were added to the polymerization polymerization, and 2.3 parts of dodecyliol regulate molecular weight is adjusted; continued to add 34 parts by weight by silicic acid. Potassium and sodium silicate by mixture of mixtures and margins combined with 1: 1; mixed with 7 parts by weight by MDBS, EDBS, and DMDBS massage 1: 1: 1 mixture and 7 parts by weight of sulfonated grapiene , Mix evenly, resulting in concrete maintenance agent # 1.

Embodiment 2

[0054] 100 parts by weight of the beta carboxyethyl acrylate, 72 parts by weight of dodecylvinyl ether, 67 parts by weight N, N-dimethyl methacrylate, 97.5 parts by weight of 2-methacrylate methoxyethyl ethyl ester The monomer and 1000 parts by weight of water mixed; 140 ° C, stirring 1.5 parts by weight of the oxidation of diothylopentalethylene-initiated polymerization, simultaneous addition of 3.5 parts of dodecyliol regulating molecular weight; continued 45 parts by weight of the silicic acid Potassium and sodium silicate massage mixtures and margins of the mixture of 1: 1; 10 parts by weight of MDBS, EDBS, and DMDBS massage 1: 1: 1 mixture and 8 parts by weight of sulfonated grapiene , Stir evenly to obtain concrete maintenance agent # 2.

Embodiment 3

[0056] 100 parts by weight of β carboxyethyl acrylate, 83 parts by weight of Dodecylvinyl ether, 58 parts by weight N, N-dimethyl methacrylate, 112 parts by weight of 2-methacrylate methoxyethyl escency The monomer and 1000 parts by weight of water were mixed; 1.3 parts by weight of the oxidative diopopentale was added to 140 ° C, stirring conditions, and 3.2 parts of dodecyllines were added to regulate molecular weight size; continued to add 40 parts by weight by silicic acid. Potassium and sodium silicate in combination of 1: 1 mixture of water; additional 8 parts by weight of MDBS, EDBS and DMDBS massage 1: 1: 1 composed of mixtures and 8 parts by weight of sulfonated graphene, stir Uniform, resulting in concrete maintenance agent # 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com