Photosensitive color-changing azobenzene polyamide and its preparation method and photosensitive color-changing nylon fiber

A photosensitive discoloration technology of azobenzene polyamide, applied in the direction of color-changing fluorescent materials, single-component polyamide artificial filaments, single-component copolyamide artificial filaments, etc., can solve the problem of poor spinning performance and unsuitable spinning Problems such as silk raw materials and poor processing performance, etc., achieve high yield, simple and reasonable preparation method, and improve high temperature resistance

Active Publication Date: 2022-06-03

WUHAN TEXTILE UNIV

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Patent CN201811380342.5 discloses a photochromic polyacrylamide supramolecular hydrogel and its preparation method, using acrylamide and azobenzenespiropyran functionalized acrylamide as reactive monomers to obtain a photochromic polymer by polymerization , in this scheme, azobenzene is in the side chain of the polymer, and the thermal stability is poor

Patent CN201910636018.3 discloses an N-linked main chain azobenzene polymer and its film preparation method. Dinitroaniline is used as a reactive monomer and polymerized under the action of a reducing agent to obtain a polymer with azobenzene as the main chain The main chain of the polymer only contains azobenzene structure, the processing performance is poor, and the function is relatively single

Patent CN201910600051.0 discloses a photochromic hyperbranched azo polyamide and its preparation method, using 4,4′-diaminoazobenzene and trimesic acid as raw materials, low-temperature solution polycondensation to obtain photochromic Functional hyperbranched azopolyamide, but the spinning performance of hyperbranched polymers is poor, so it is not suitable as spinning raw materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0048] The brominated alkane is preferably an alkane group having 5 to 10 carbon atoms.

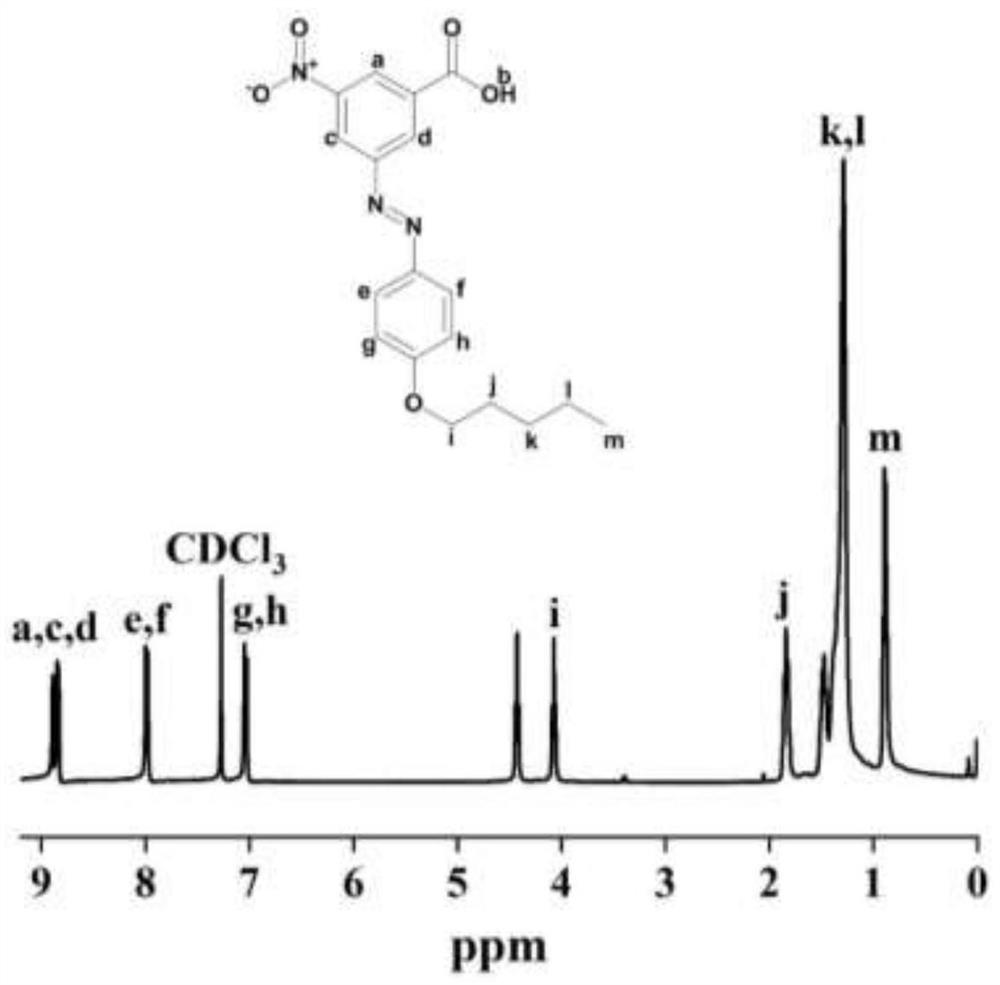

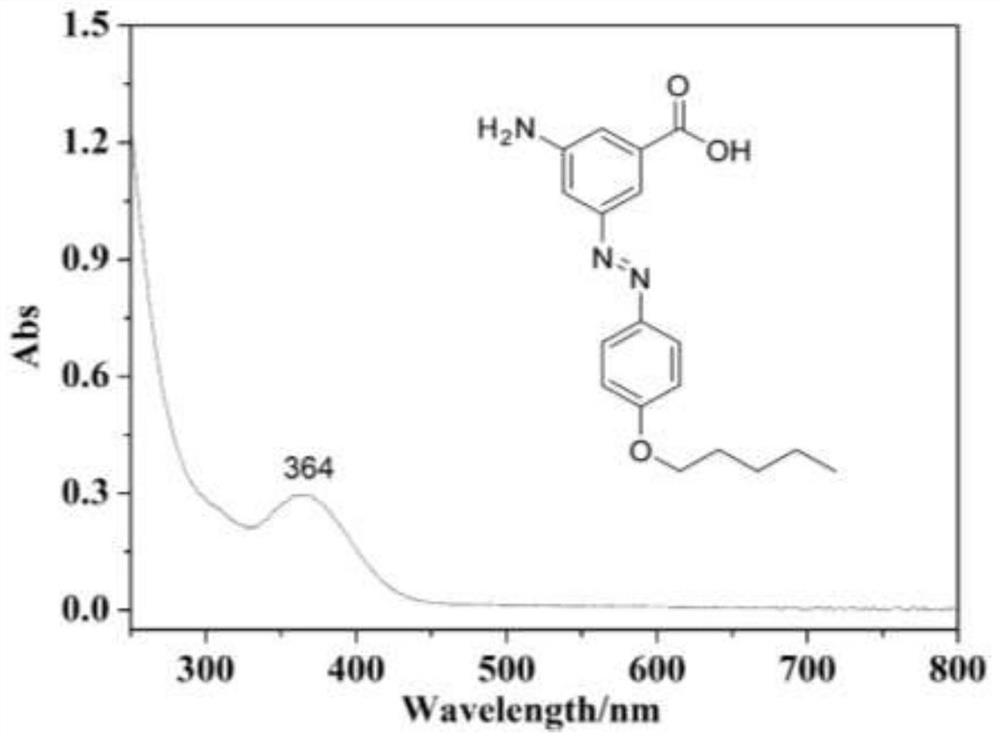

[0051]

[0053]

[0059]

Embodiment 1

[0063]

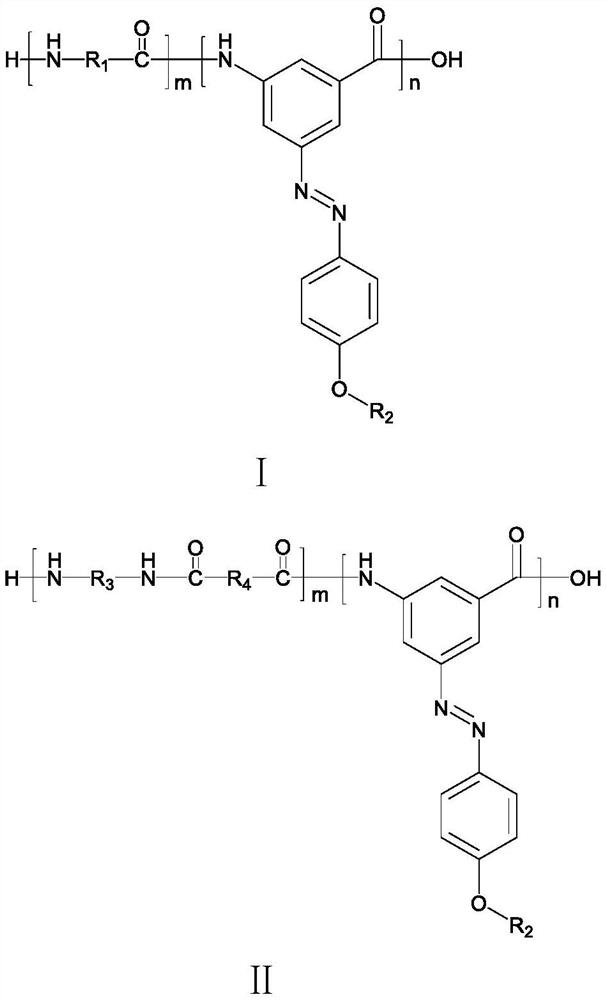

[0064] where m is about 330 and n is about 15.

Embodiment 2-4 and comparative example 1-2

[0080]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a photosensitive color-changing azobenzene polyamide, a preparation method thereof and a photosensitive color-changing nylon fiber. The photosensitive color-changing azobenzene polyamide comprises a polyamide chain segment and an azobenzene derivative chain segment, and a benzene ring structure in the azobenzene derivative chain segment is on the main chain of the photosensitive color-changing azobenzene polyamide. First prepare a carboxy azobenzene derivative containing an alkane group and an amino group, and the amino group and the carboxyl group are on the same benzene ring, and use it as a polymerized monomer to conduct a reaction with a lactam or with an alkane-based polyamine and an alkane-based polybasic acid. Melt polymerization to obtain azobenzene polyamide. In the present invention, by embedding the azobenzene structure into the nylon molecular chain, the polyamide has a photosensitive discoloration function and has good melt spinning performance, and the nylon fiber obtained by melt spinning has good mechanical properties and photosensitive discoloration Function.

Description

Photochromic azobenzene polyamide and preparation method thereof, and photochromic nylon fiber technical field The present invention relates to functional polymer material technical field, relate in particular to a kind of photosensitive color changing azobenzene polyamide and Its preparation method and photochromic nylon fiber. Background technique As one of the five major engineering plastics, polyamide (nylon) has high tensile strength, large elastic modulus, wear resistance and Excellent self-lubrication and other characteristics, it has been widely used in automobile manufacturing, electrical and electronic industries, machinery and equipment and packaging industries. application. With the development of science and technology and the improvement of people's living standards, people put forward higher requirements for the color of clothing. Not only do we need the right color, but we also hope that the color of the pattern can also change with the light. Photo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G69/12D01F6/60D01F6/80C09K9/02

CPCC08G69/12D01F6/605D01F6/80C09K9/02

Inventor 王栋王雯雯易礼婷卢静周鹏程严忠

Owner WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com