Processing technology and application of hydrophilic polylactic acid fibers

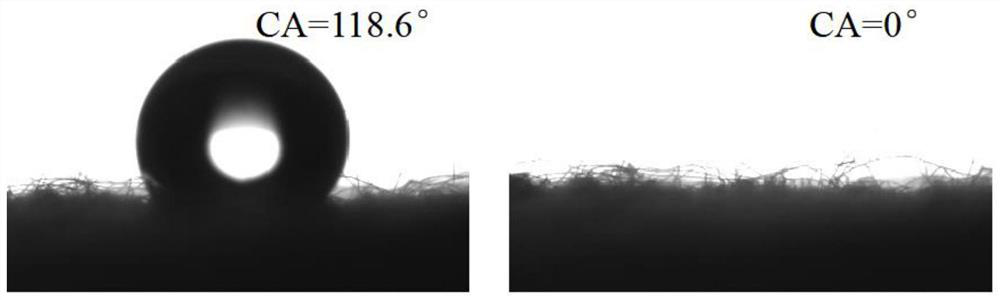

A polylactic acid fiber and processing technology technology, applied in fiber type, fiber processing, medical science and other directions, can solve the problems of complex cell affinity process, decreased mechanical strength, lack of comfort on the surface of PLA tissue engineering materials, etc., to improve Biocompatibility, Surface Contact Angle Reduction, Low Cost Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of ChCl-OA deep eutectic solvent: Accurately weigh choline chloride and oxalic acid according to the ratio of substances to 1:1-1.5, add them to the Erlenmeyer flask in turn, put in a magnetic stirrer, and place in a constant temperature magnetic On a stirrer, stir and dissolve at 90-100°C until the system is completely dissolved to a transparent state, and then continue to stir for 0.5-1.5h to prepare ChCl-OA DES for later use.

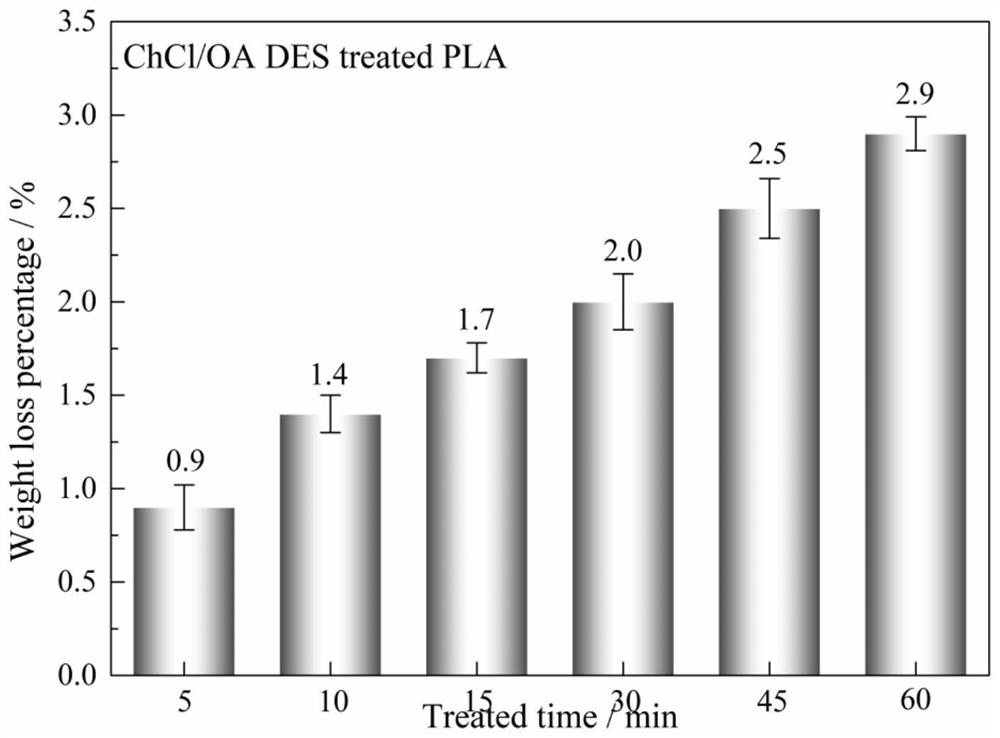

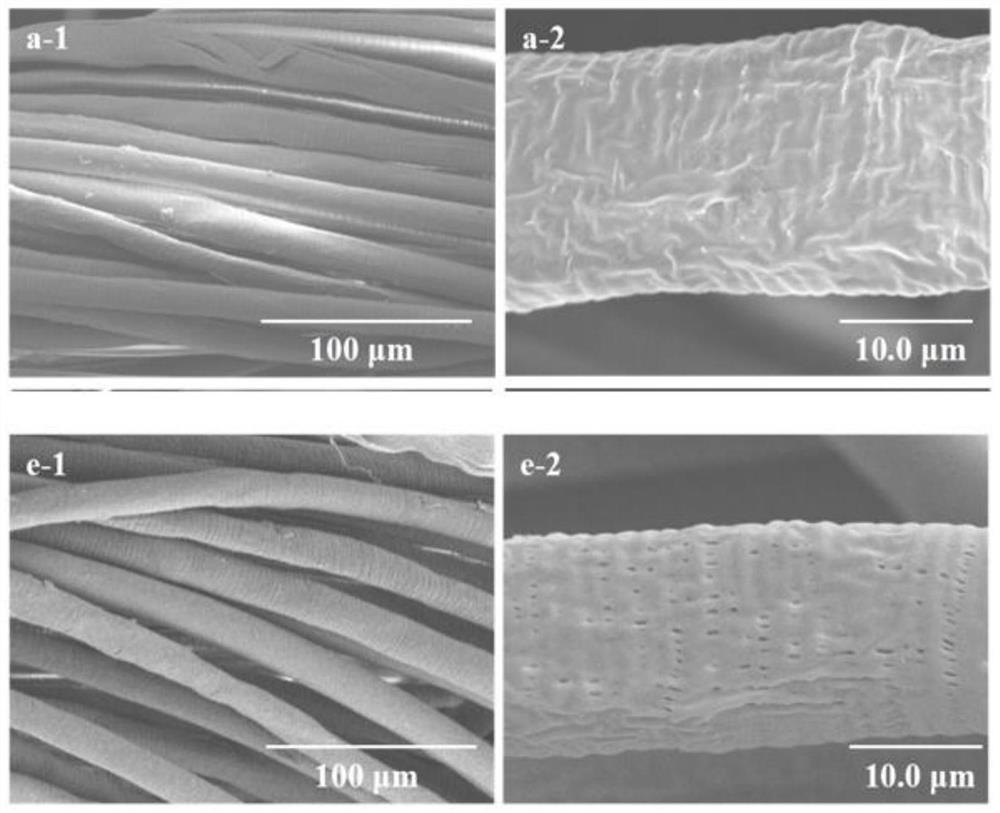

[0032] Treatment of PLA fibers and fabrics with ChCl-OA deep eutectic solvent: PLA fibers are pre-deoiled with 0.3-0.8g / L sodium carbonate solution (at 38-45°C for 5-20min), and then impregnated in the pre-prepared In the completed ChCl-OA system (the mass ratio of polylactic acid fiber to the system is 1:20-30), treat it at 40-70°C for 5-180min, then take it out and wash it with distilled water, dry it at 100°C, and wait for the test .

[0033] The following is illustrated by specific examples:

Embodiment 1

[0035] 1. Preparation of ChCl-OA deep eutectic solvent: Accurately weigh choline chloride and oxalic acid according to the ratio of substances to 1:1. On a stirrer, stir at 95°C to aid dissolution until the system is completely dissolved to a transparent state, and then continue to stir for 1 hour to prepare ChCl-OA DES for later use.

[0036] 2. Treatment of PLA fibers and fabrics with ChCl-OA deep eutectic solvent: PLA fibers are pre-deoiled with 0.5g / L sodium carbonate solution (at 40°C for 10 minutes), and then impregnated in pre-prepared ChCl- In the OA system (the mass ratio of polylactic acid fiber to the system is 1:25), treat it at 55°C for 60 minutes, then take it out and wash it with distilled water, dry it at 100°C, and wait for the test.

Embodiment 2

[0038] 1. Preparation of ChCl-OA deep eutectic solvent: Accurately weigh choline chloride and oxalic acid according to the ratio of substances to 1:1.5. On a stirrer, stir at 100°C to aid in dissolution until the system is completely dissolved to a transparent state, and then continue to stir for 0.5h to prepare ChCl-OA DES for later use.

[0039] 2. Treatment of PLA fibers and fabrics with ChCl-OA deep eutectic solvent: PLA fibers are pre-deoiled with 0.5g / L sodium carbonate solution (at 40°C for 15 minutes), and then impregnated in pre-prepared ChCl- In the OA system (the mass ratio of polylactic acid fiber to the system is 1:30), treat it at 60°C for 60 minutes, then take it out and wash it with distilled water, dry it at 100°C, and wait for the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com