Silicon-based negative electrode material, preparation method thereof and lithium ion battery

A silicon-based negative electrode material and silicon-based technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve problems such as unsatisfactory cycle and safety, easy decomposition of electrolyte, cycle performance, and unstable electrochemical performance. , to achieve enhanced structural stability and cycle performance, stable structure and electrochemical performance, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

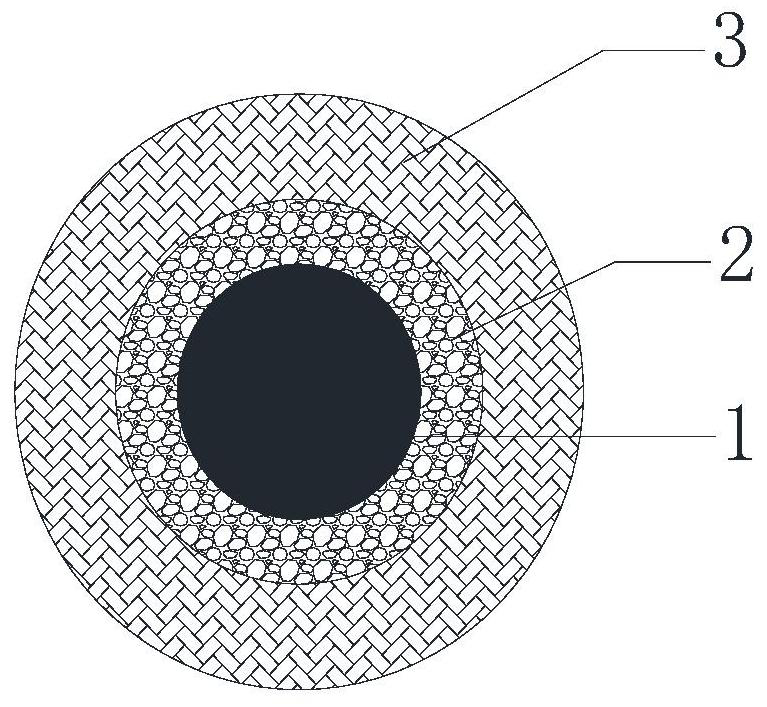

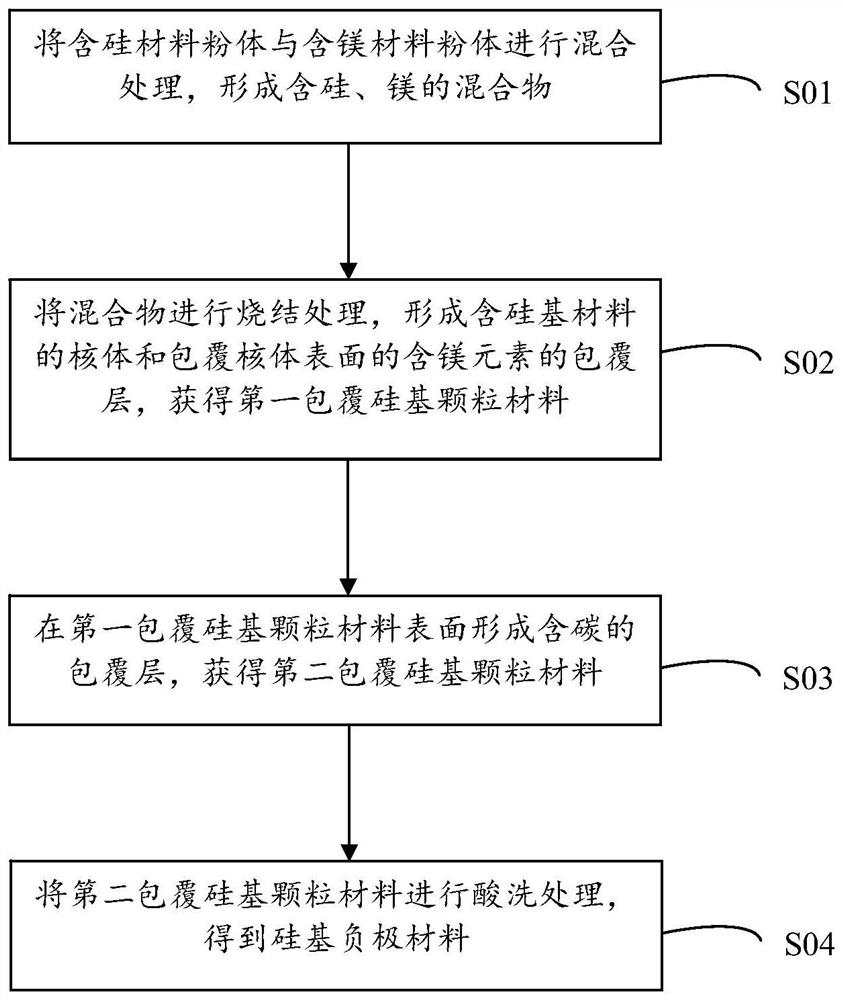

[0047] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned silicon-based negative electrode material. The process flow of the preparation method of the silicon-based negative electrode material is as follows: figure 2 As shown, combined with figure 1 , its preparation method comprises the following steps:

[0048] Step S01: Mixing silicon-containing material powder and magnesium-containing material powder to form a mixture containing silicon and magnesium;

[0049] Step S02: Sintering the mixture to form a silicon-based material-containing core body 1 and a magnesium-containing coating layer covering the surface of the core body to obtain the first coated silicon-based granular material;

[0050] Step S03: forming a carbon-containing coating layer (shell layer 3) on the surface of the first coated silicon-based granular material to obtain a second coated silicon-based granular material;

[0051] Step S04: pickl...

Embodiment 1

[0093] This embodiment provides a silicon-based negative electrode material and a preparation method thereof. The structure of the silicon-based negative electrode material is as follows figure 1 As shown, it is a double-shell core-shell structure, and the material of the core body 1 is SiO x particles, whose D50 is 10 μm; the inner shell layer 2 is distributed with rich microporous structure, and the micropores contained in the microporous structure are arranged along the direction from the core body 1 to the outer shell layer 3, and the pore size of the micropores is determined by the core body 1 gradually increases toward the shell layer 3, the average pore diameter of the micropores is 1000nm, and its materials include magnesium oxide, Mg 2 SiO 4 , MgSiO 3 mixture, with an average thickness of 5nm; the shell layer 3 is a vapor-deposited conductive carbon layer, with an average thickness of 100nm.

[0094] The preparation method of silicon-based negative electrode mater...

Embodiment 2

[0100] This embodiment provides a silicon-based negative electrode material and a preparation method thereof. The structure of the silicon-based negative electrode material is as follows figure 1 As shown, it is a double-shell core-shell structure, and the material of the core body 1 is silicon microcrystal and amorphous silicon oxide SiO x A mixture of particles, the content of silicon microcrystals accounts for 2-30wt% of the total weight of silicon microcrystals and silicon oxides, and its D50 is 20 μm; there are abundant microporous structures distributed on the inner shell 2, and the microporous structures contained in the microporous structure The pores are arranged along the direction from the core body 1 to the outer shell layer 3, and the pore diameter of the micropores gradually increases from the core body 1 to the outer shell layer 3. The average pore diameter of the micropores is 2000nm, and its materials include magnesium oxide, Mg 2 SiO 4 , MgSiO 3 mixture, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com