Visual fucoidin embolization microsphere and preparation method thereof

A fucoidan and microsphere technology, which is applied in the field of visualized fucoidan embolization microspheres and its preparation, can solve the problems of small selectivity, few types, and high technical threshold, and achieves high-efficiency drug loading and is conducive to large-scale production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

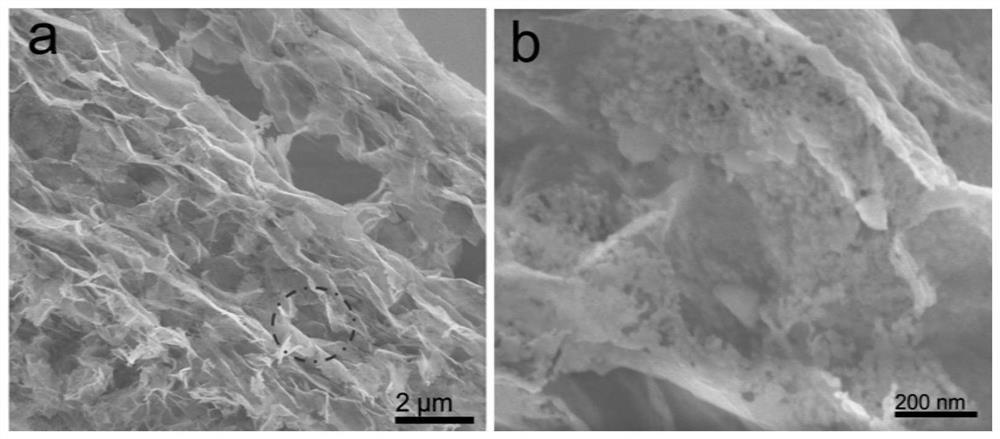

[0063] In this method, microspheres are carried out primarily, and polymerization reactions are achieved in this process. Specifically, the method mainly includes three steps, and decibel is: (1) preparation of the macromolysaccharide molar of unsaturated bond; (2) formation of membrane emulsification, continuous phase; (3) The dispersion phase and the continuous phase reaction obtain the embolization microspheres. Obviously, in the foregoing steps, two steps (1) and step (2) can be performed simultaneously, or other sequential performed, and is not implemented in the order described above. In other words, the preparation method proposed in the present application is a backup step, and the step of polymerizing the polymerization using the prepared material to form a plug microsphere.

[0064] Among them, the preparation method of the unsaturated bonded fucose polysaccharide macromolecule is as follows:

[0065] The first solution was obtained in a basic solution in an amount of fr...

Embodiment 1

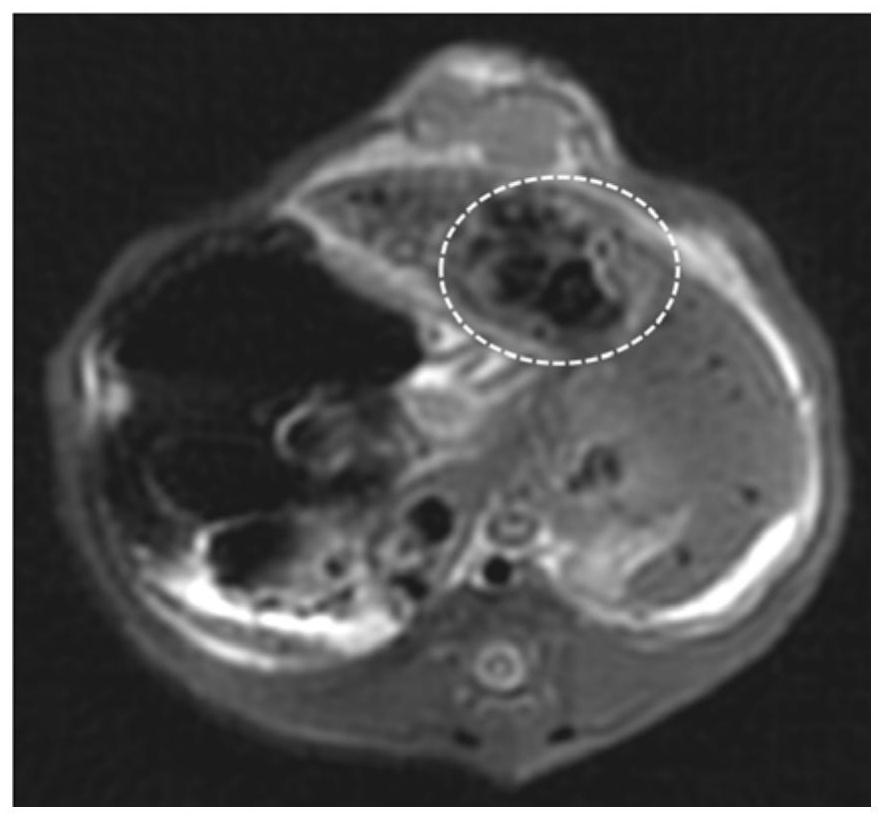

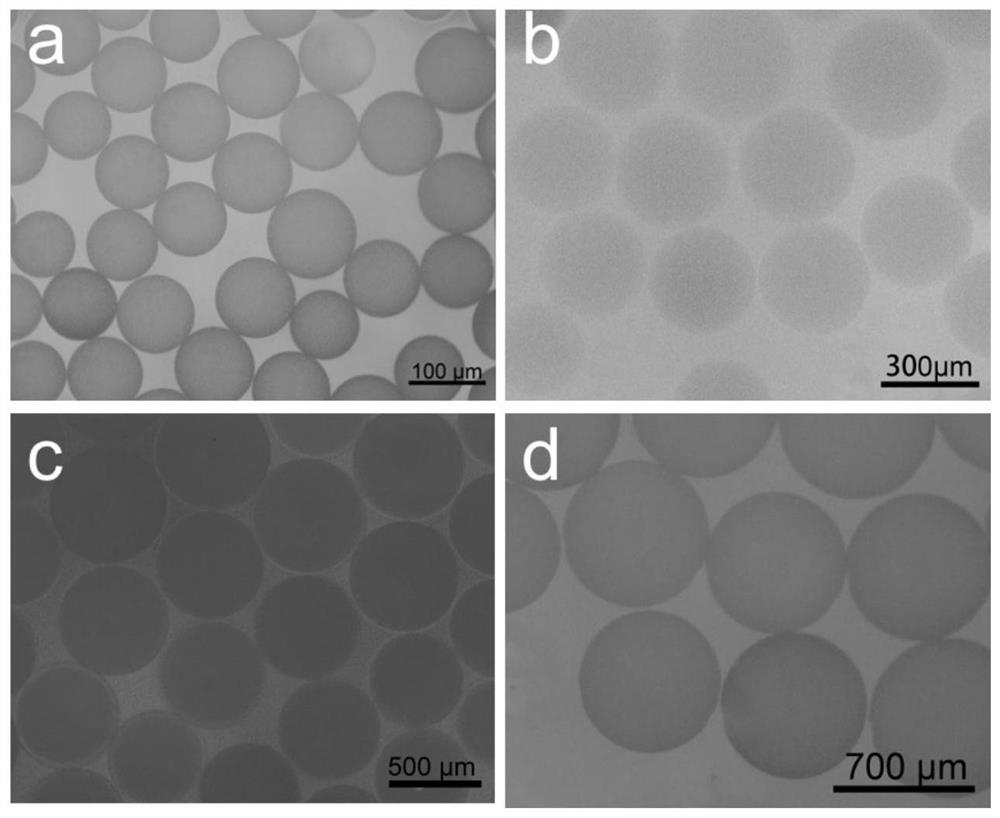

[0086] Preparation of visualized carine polysaccharols microspheres, including the following steps:

[0087] Step 1: Preparation of functionalized carine polysaccharide mons:

[0088] 50 g of a 50 mLPH = 8.0 was dissolved in aqueous solution of 150 mLPH = 8.0, and a 20% aqueous polysaccharide solution was disposed in a mass concentration; then 10 ml of acrylic acid and 0.2 g of carboxy-modified tetrasoxide three iron nanoparticles were added to the system. The above-mentioned system temperature was raised to 65 ° C, 400 rpm was stirred for 10 h, i.e., the unsaturated bond and the tetraned iron-modified fucose polysaccharide; finally used ethanol as a precipitant, was reversed, washed, and vacuum dried to functionify Magnetic fucodaine intermediate.

[0089] Step 2: Formulation of membrane emulsification method:

[0090] Take 10G steps to dissolve the unsaturated bond in step one in 30 ml of water, stirred at 70 ° C, stirred evenly, 300 rpm is mixed, resulting in a 20% polysacchari...

Embodiment 2

[0096] Preparation of visualized carine polysaccharols microspheres, including the following steps:

[0097] Step 1: Preparation of functionalized carine polysaccharide mons:

[0098] 50 g of fucose solid was dissolved in 150 mL of pH = 8.0, a sodium carbonate water solution was configured to 25% aqueous polysaccharide solution of mass concentration; then 10 ml of acrylic acid and 0.6 g of carboxy-modified tetraned iron was added to the system. Nanoparticles.

[0099] The above-mentioned system temperature was raised to 65 ° C, 400 rpm. The mixture was stirred for 10 h, i.e., the aqueous unsaturated bonded fucosaccharide aqueous solution; finally used ethanol as a precipitant, was reversed, washed, vacuum dried to obtain a functionalized magnetic calamine. Polysaccharide intermediate.

[0100] Step 2: Formulation of membrane emulsification method

[0101] Take 10G steps to dissolve the unsaturated bond in step one in 30 ml of water, stirred at 70 ° C, stirred evenly, 300 rpm is mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com