Method for preparing functional coating containing nano-silver antibacterial peptide on metal surface

A metal surface, antibacterial peptide technology, applied in coating, medical science, prosthesis, etc., can solve the problem of inability to cope with bacterial infection environment, drug resistance, etc., to solve bacterial drug resistance, reduce dosage, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

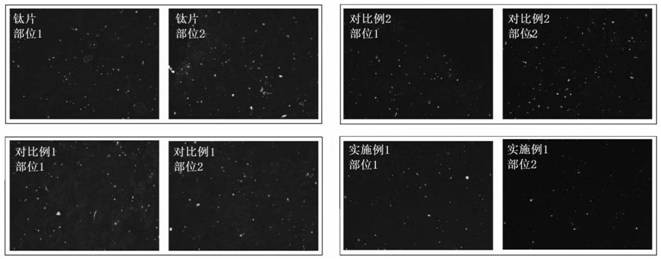

Image

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] Step 1. Place the silk in 0.02M Na 2 CO 3 Boil in the solution for 40 minutes, take it out, rinse it with deionized water, and then add it to 9.3M LiBr solution at 60°C for 4 hours to obtain the silk fibroin stock solution;

[0032] The silk fibroin stock solution is diluted with deionized water into a silk fibroin solution with a mass concentration of 2%, and then 17mg of silver nitrate powder and 4mg of antimicrobial peptide powder are added to 10mL of the silk fibroin solution with a mass concentration of 2% and mixed to obtain a silk fibroin solution containing 2% mass concentration. The mixed solution A of protein, silver ion and antimicrobial peptide and pH is 8.5;

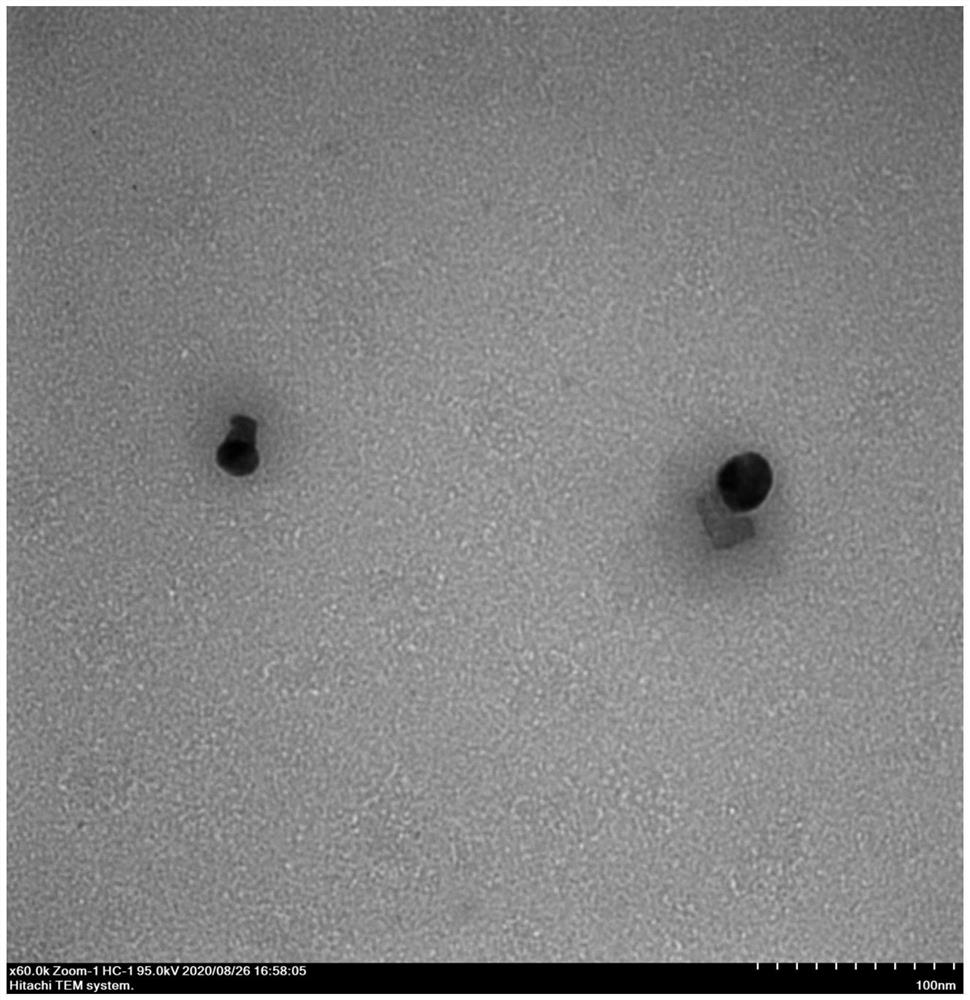

[0033] Step 2. Place the mixed solution A obtained in step 1 under a 40W ultraviolet lamp for irradiation and reduction for 0.5h, so that the color of the mixed solution A gradually changes from milky white to dark brown, and obtains silk fibroi...

Embodiment 2

[0054] This embodiment includes the following steps:

[0055] Step 1. Place the silk in 0.02M Na 2 CO 3 Boil in the solution for 40 minutes, take it out, rinse it with deionized water, and then add it to 9.3M LiBr solution at 60°C for 4 hours to obtain the silk fibroin stock solution;

[0056] The silk fibroin stock solution was diluted with deionized water into a silk fibroin solution with a mass concentration of 3%, and then 10 mg of silver nitrate powder and 8 mg of antimicrobial peptide powder were added to 10 mL of a silk fibroin solution with a mass concentration of 3% and mixed to obtain a silk fibroin solution containing 3% mass concentration. Protein, silver ion and antimicrobial peptide and the mixed solution A that pH is 8;

[0057] Step 2. Place the mixed solution A obtained in step 1 under a 40W ultraviolet lamp for irradiation and reduction for 1 hour, so that the color of the mixed solution A gradually changes from milky white to dark brown, and a mixed soluti...

Embodiment 3

[0061] This embodiment includes the following steps:

[0062] Step 1. Place the silk in 0.02M Na 2 CO 3 Boil in the solution for 40 minutes, take it out, rinse it with deionized water, and then add it to 9.3M LiBr solution at 60°C for 4 hours to obtain the silk fibroin stock solution;

[0063] Dilute the silk fibroin stock solution with deionized water into a silk fibroin solution with a mass concentration of 5%, then add 200 mg of silver nitrate powder and 10 mg of antimicrobial peptide powder into 10 mL of a silk fibroin solution with a mass concentration of 5% and mix to obtain a silk fibroin solution containing 5% mass concentration. Protein, silver ion and antimicrobial peptide and the mixed solution A that pH is 10;

[0064] Step 2. Place the mixed solution A obtained in step 1 under a 40W ultraviolet lamp for irradiation and reduction for 2 hours, so that the color of the mixed solution A gradually changes from milky white to dark brown, and a mixed solution containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com