Preparation method of Mxene membrane adsorption material based on polyamidoxime and uranium extraction method

A polyamidoxime, membrane adsorption technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, nuclear engineering and other directions, can solve the problems of reduced adsorption efficiency, shortage of uranium resources, and many preparation steps, etc., to improve adsorption efficiency. , Huge application prospects, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Choose Ti 3 AlC 2 Raw materials required for the reaction. At a temperature of 10°C, 0.1g of Ti 3 AlC 2 Add it to 20mL of 0.1mol / L HF solution for pretreatment for 0.5 hours. During the pretreatment process, continuously add 0.1mol / L NaOH solution dropwise through the automatic titration system to maintain the pH at 7; at a temperature of 30°C, The preprocessed Ti 3 AlC 2 Added into 60mL, pH = 6, DMSO solution with a concentration of 1.4mol / L, and ultrasonicated for 0.1 hour at 80% ultrasonic power; after ultrasonication, Ti 3 AlC 2 Take it out and dry it to get the Mxene film; under the conditions of temperature 20°C and pH=6, soak the Mxene film in a PAO solution with a concentration of 5mol / L and a number average molecular weight of 110,000 for 6 hours; after the reaction, Under the condition of vacuum degree of 0.17 MPa, the amidoximation modified Mxene membrane (Mxene-PAO) was obtained by vacuum filtration.

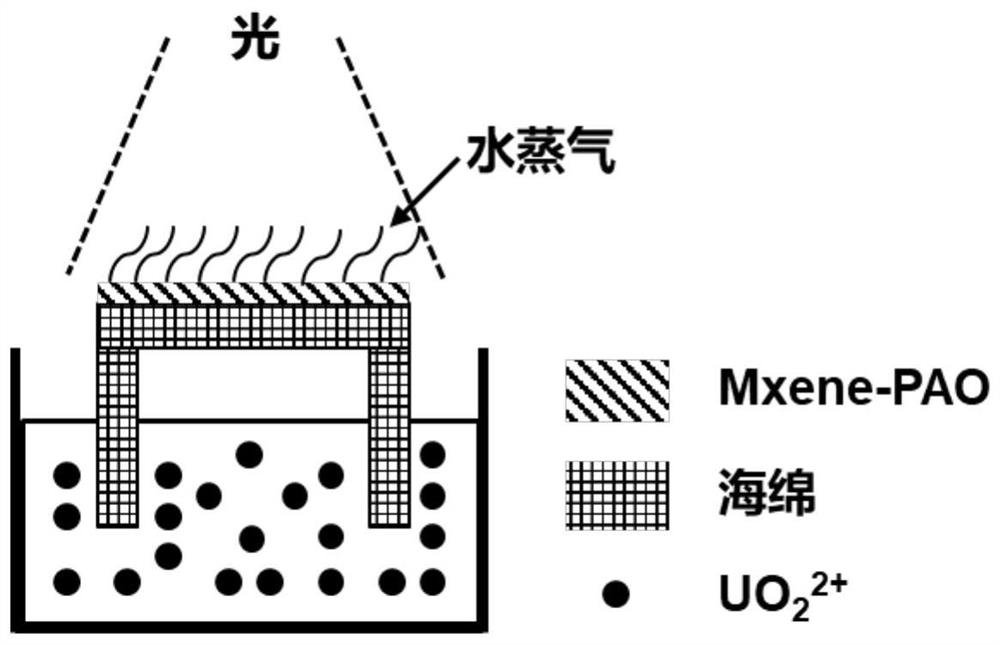

[0042] Place the dried Mxene-PAO on top of the s...

Embodiment 2~9

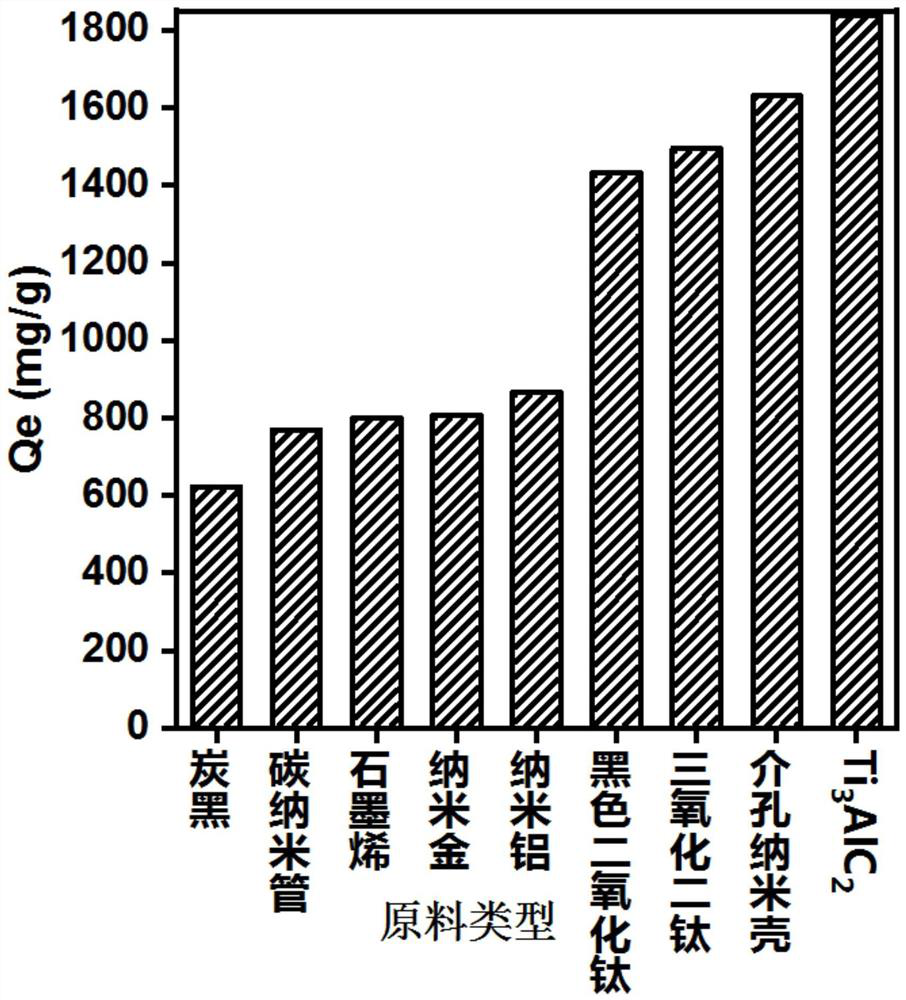

[0044] Carbon black, carbon nanotubes, graphene, nano-gold, nano-aluminum, black titanium dioxide, titanium dioxide, and hollow bimetallic plasma mesoporous nanoshells were selected as raw materials, and other conditions were the same as in Example 1. The results show that with Ti 3 AlC 2 The adsorption performance of the Mxene-PAO membrane as the raw material is the best (see image 3 ).

[0045]

Embodiment 10~14

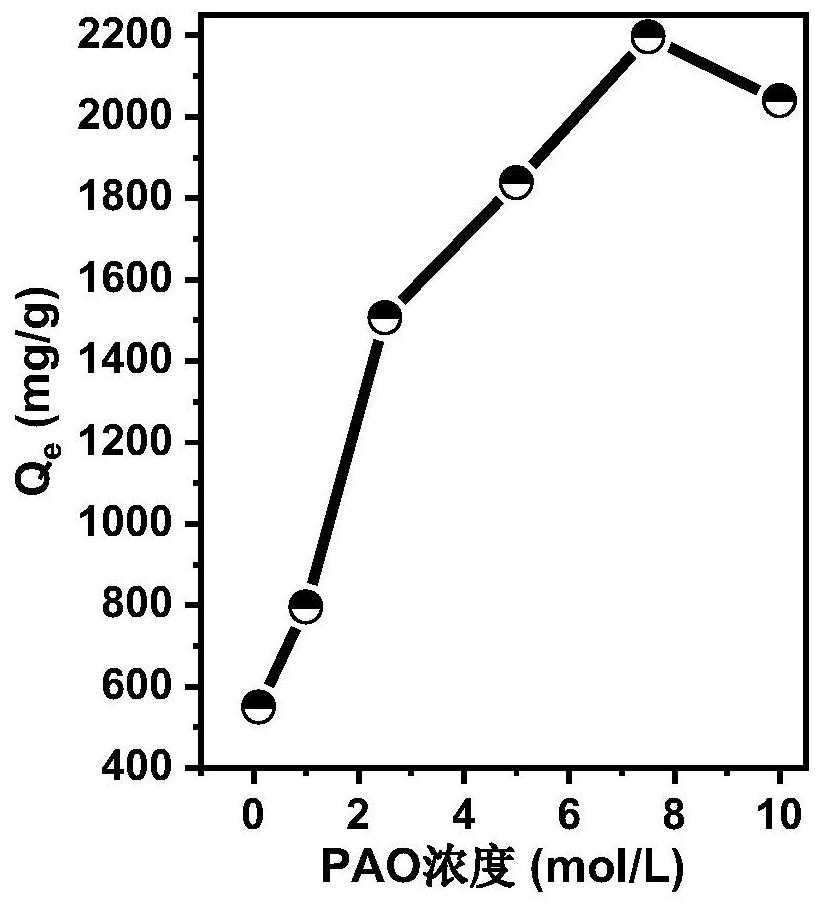

[0047] PAO concentration is respectively 0.1mol / L, 1mol / L, 2.5mol / L, 7.5mol / L, 10mol / L, other conditions are the same as example 1. The results show that the adsorption performance is the best when the PAO concentration is 7.5mol / L (see Figure 4 ).

[0048] test PAO concentration Uranium adsorption performance (mg / g) Example 10 0.1mol / L 549.76 Example 11 1mol / L 795.23 Example 12 2.5mol / L 1505.69 Example 13 7.5mol / L 2196.34 Example 14 10mol / L 2039.71

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com