Chromatographic separation filler applied to fructo-oligosaccharide, preparation process and chromatographic separation device

A technique for chromatographic separation and fructooligosaccharide, which is applied in the field of fructooligosaccharide chromatographic separation packing, preparation technology and chromatographic separation device, can solve the problems of poor separation effect, difficult operation, complicated steps and the like, and achieves excellent separation effect and preparation. Simple method and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

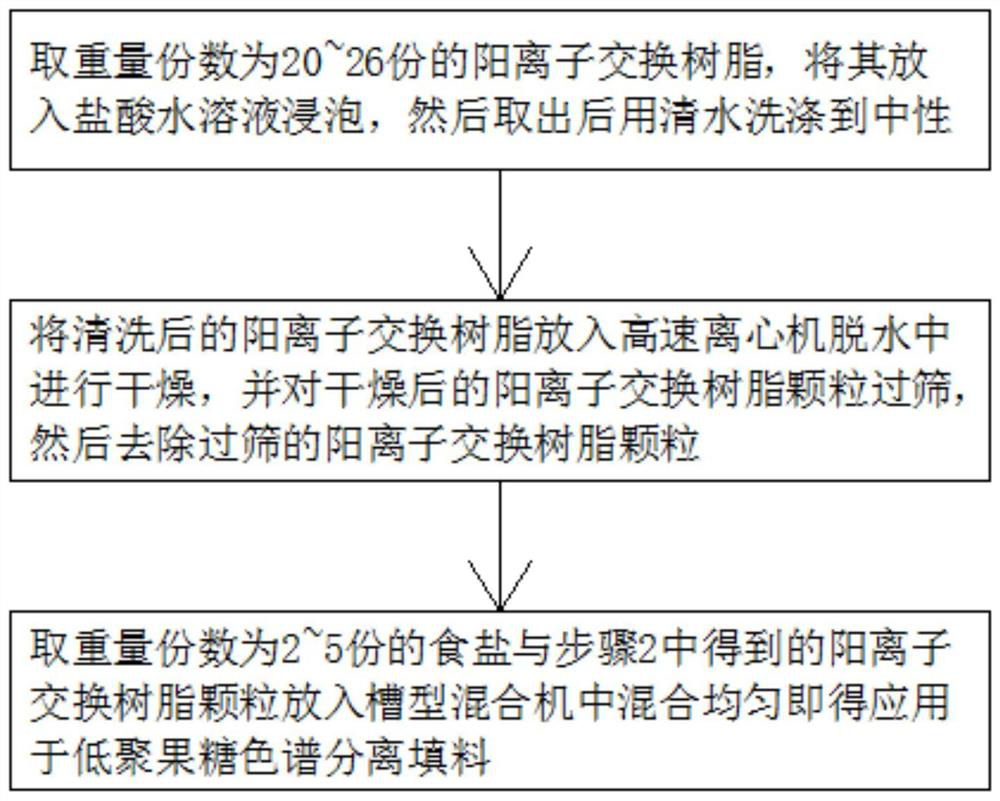

Method used

Image

Examples

Embodiment 1

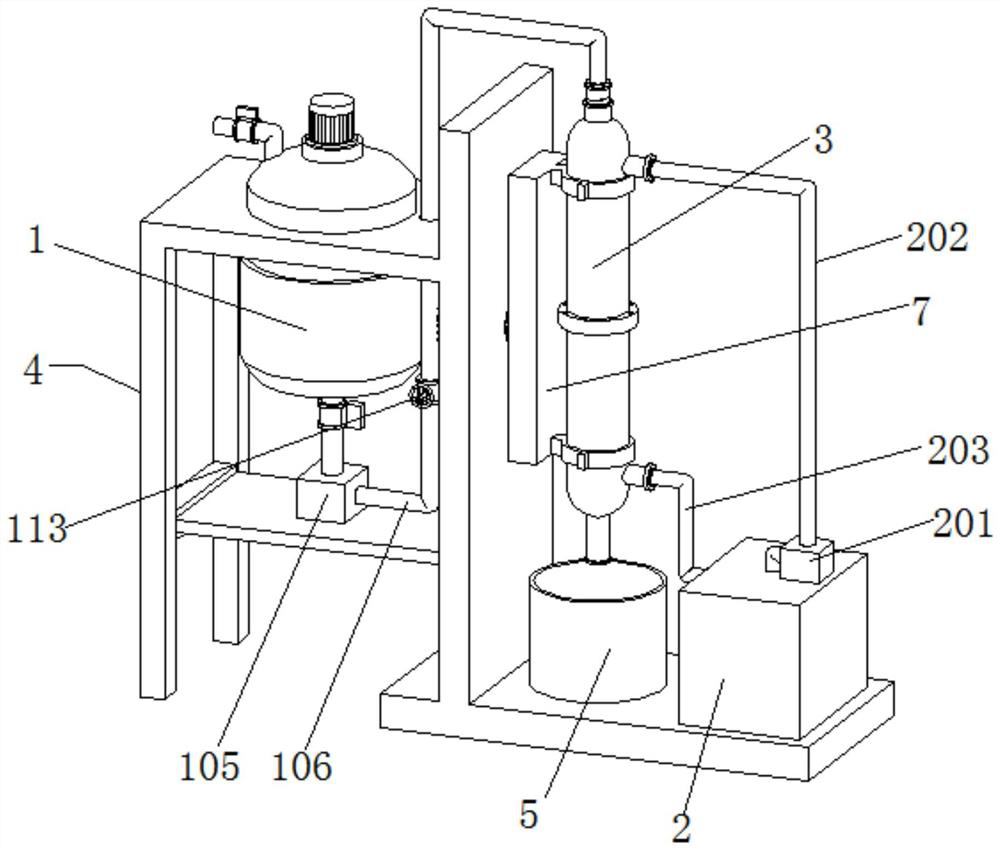

[0060] Based on the above formula and process, this embodiment 1 discloses a chromatographic separation device applied to fructooligosaccharide chromatographic separation packing, refer to the attached figure 2 And attached image 3 , its main components include a fructooligosaccharide slurry tank 1, a constant temperature water tank 2, a chromatographic separator 3, a frame 4 and a receiving bucket 5.

[0061] Reference attached Figure 6 , the frame 4 includes a base plate 400, a vertical plate 401, two legs 402 and a horizontal mounting plate 403, the vertical plate 401 is fixed on the upper surface of the base plate 400, and the horizontal mounting plate 403 is fixedly connected to the upper end of the left side of the vertical plate 401, Two legs 402 are connected with the left end of the lower surface of the horizontal mounting plate 403. The horizontal mounting plate 403 is provided with a tank mounting hole 4031, and the fructooligosaccharide slurry tank 1 is fixedly...

Embodiment 2

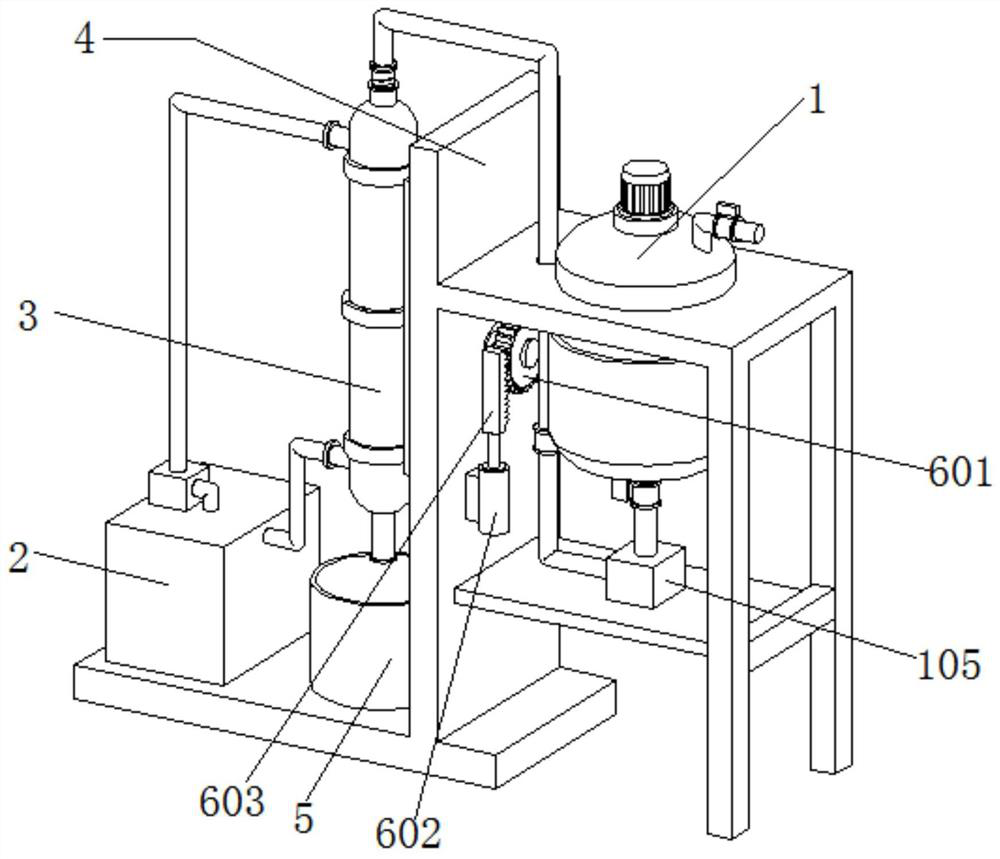

[0069] Embodiment 2 discloses an improved chromatographic separation device applied to fructooligosaccharide chromatographic separation filler based on embodiment 1. Its similarities with embodiment 1 will not be described again. For the differences, please refer to the attached Figure 4 And attached Figure 5 .

[0070] Present embodiment 2 is also provided with motor support 107 on the upper end of fructo-oligosaccharide slurry tank 1, and motor support 107 is provided with stirring motor 108, and the output shaft of stirring motor 108 stretches in the fructo-oligosaccharide slurry tank 1, and stirring motor 108 The end of the output shaft is connected with a stirring shaft 109 through a coupling, and a plurality of stirring blades 110 are arranged at the lower end of the stirring shaft 109 . Then, the outer surface of the lower end of the fructooligosaccharide slurry tank 1 is provided with a thermal insulation jacket 111, and a spiral resistance heating wire 112 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com