Method for separating and purifying dilinoleoylphosphatidylcholine and dilinoleoylphosphatidylcholine product

A technology for purifying dilinoleoylphosphatidylcholine and dilinoleoylphosphatidylcholine, which is applied in chemical instruments and methods, edible phospholipid compositions, organic chemistry, etc., can solve adverse product safety and environmental friendliness, purity Limited and other problems, to achieve the effect of strong separation ability, simple and controllable operation, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

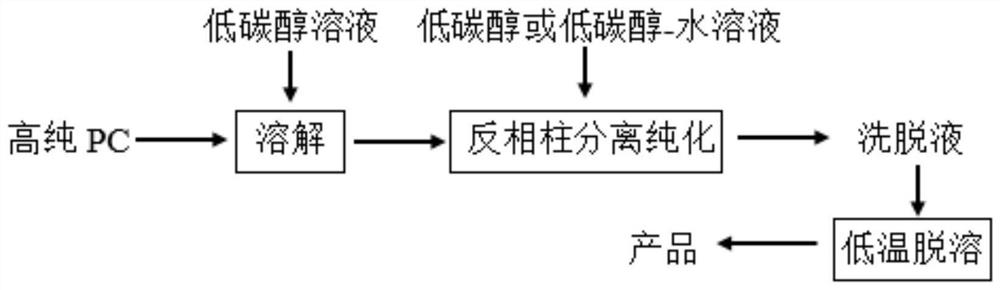

[0031] This embodiment provides a method for separating and purifying dilinoleoylphosphatidylcholine and dilinoleoylphosphatidylcholine products, the separation and purification flow chart is as follows figure 1 shown.

[0032] Preparation of sample solution: take 2 g of high-purity phosphatidylcholine (the content of phosphatidylcholine is 90 wt%, and the content of dilinoleoylphosphatidylcholine is 28 wt%), and dissolve the sample in 0.5 mL ethanol.

[0033] Separation and purification: the sample solution is separated and purified by a preparative column system, all the sample solution is injected, and the preparative chromatographic column uses C18 packing with a particle size of 20-35 μm and a pore size of The packing mass is 45g, the flow rate is 0.1bv / min; the elution solvent is methanol solution, and the detection wavelength is 203nm. Receive the eluent from the peak of the target peak until the target peak returns to the baseline position, receive the eluent every 0...

Embodiment 2

[0035] Sample loading solution preparation: take 0.4 g of high-purity phosphatidylcholine (the content of phosphatidylcholine is 93wt%, the content of dilinoleoylphosphatidylcholine is 32wt%), and dissolve the sample in 0.5mL ethanol.

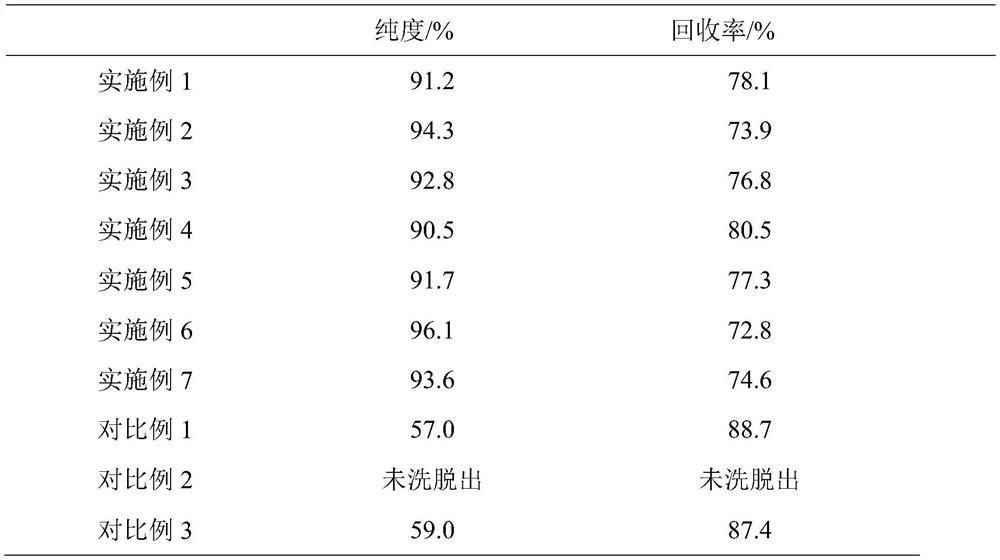

[0036] Separation and purification: the sample solution is separated and purified by a preparative column system, all the sample solution is injected, and the preparative chromatographic column uses C18 packing with a particle size of 20-35 μm and a pore size of The packing mass is 40g, the flow rate is 0.3bv / min; the elution solvent is aqueous methanol (65:35, v / v), and the detection wavelength is 203nm. Receive the eluent from the peak of the target peak until the target peak returns to the baseline position, receive the eluent every 0.5min, analyze the purity of DLPC by HPLC-UV, combine the eluents that detect DLPC, and combine the elution The solution was subjected to low-temperature precipitation and drying, and the purity and recovery ra...

Embodiment 3

[0038] Preparation of sample solution: take 4 g of high-purity phosphatidylcholine (the content of phosphatidylcholine is 95wt%, and the content of dilinoleoylphosphatidylcholine is 36wt%), and dissolve the sample in 0.5mL ethanol.

[0039] Separation and purification: the sample solution is separated and purified by a preparative column system, all the sample solution is injected, and the preparative chromatographic column uses C18 packing with a particle size of 20-35 μm and a pore size of The packing mass is 35g, the flow rate is 0.6bv / min; the elution solvent is aqueous methanol (50:50, v / v), and the detection wavelength is 203nm. Receive the eluent from the peak of the target peak until the target peak returns to the baseline position, receive the eluent every 0.5min, and combine the eluents that detect DLPC through HPLC-UV analysis, and then carry out the combined eluent. Low-temperature precipitation and drying, the purity and recovery rate of the obtained dilinoleoylp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com