High-reverse-shift elastic biomass water-based PU (Polyurethane) resin and formula development technology

A biomass and reaction technology, applied in the field of polymer materials, can solve the problems of poor adhesion of substrates or substrates, limiting the development and application of biomass water-based PU, and difficulty in controlling the molecular weight and quality of synthetic polyester polyols.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

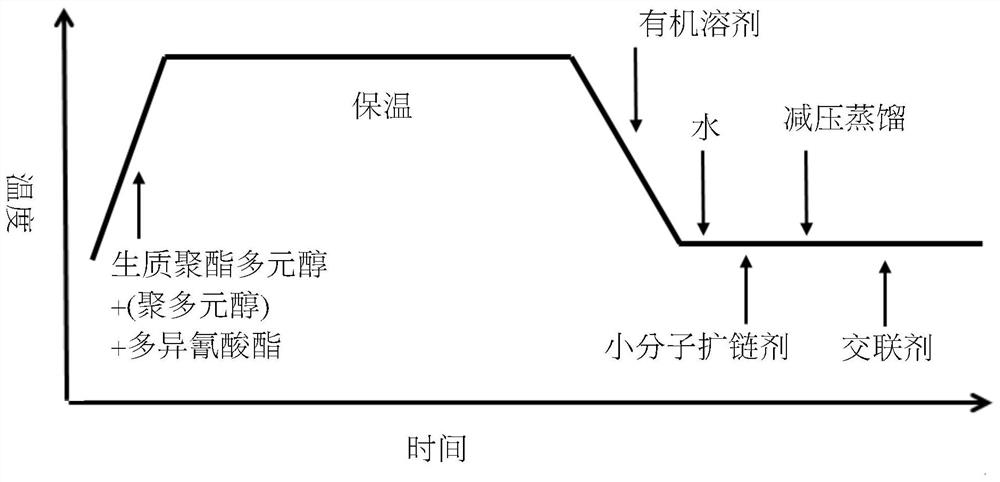

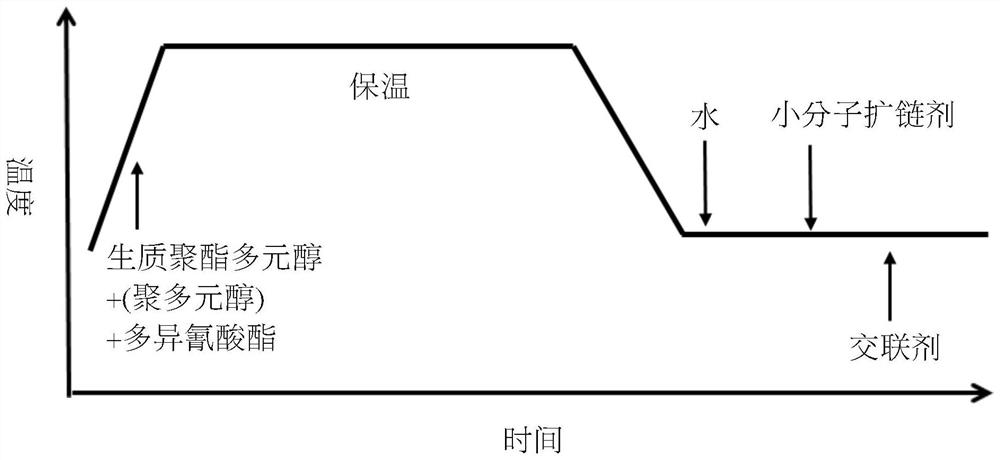

Method used

Image

Examples

preparation example Construction

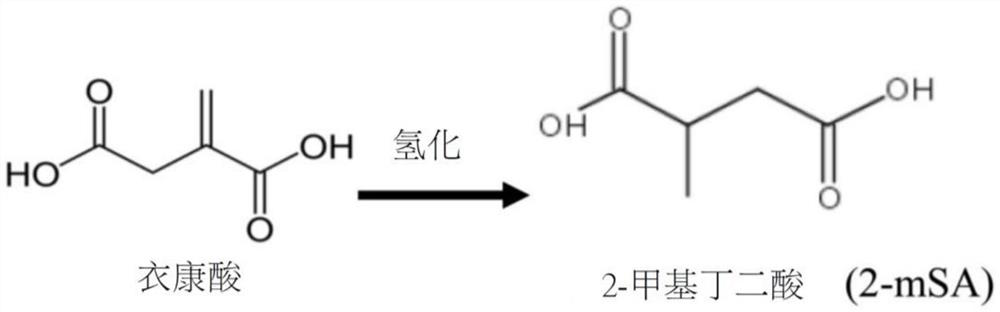

[0036] Preparation method of polyester polyol with high biomass content

[0037] The method for producing the polyester polyol used in the present invention includes reacting 2-methylsuccinic acid with dibasic alcohol and dibasic acid further added as the case may be.

[0038] In a specific example of preparing the polyester polyol used in the present invention, the method for preparing the polyester polyol with high biomass content at least comprises the following steps:

[0039] (1) Add alkyl polyol, alkyl polyacid and antioxidant system to the reactor;

[0040] (2) Carry out the reaction at a temperature not higher than 160°C in a stable gas environment and then increase the reaction temperature to 180-230°C to continue the reaction;

[0041] (3) When the acid value is lower than the first target value, apply a vacuum condition to the reactor and make the reaction continue;

[0042] (4) the reaction is completed when the acid value is lower than the second target value; ...

example

[0081] The present invention is further described in detail through the following examples. It is necessary to point out that the following examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, and those skilled in the art make some non-essential improvements to the present invention according to the above-mentioned content of the present invention And adjustments still belong to the protection scope of the present invention. Before discussing several non-limiting embodiments of the invention, it is to be understood that the invention is not limited in its application to the details of the particular non-limiting embodiments shown and discussed herein, as the invention is capable of other embodiments. Furthermore, the terminology used herein to discuss the present invention is for the purpose of description and not limitation. Furthermore, the discussion of like numbers below re...

example 1

[0085] Weigh 200g of biomass polyester polyol (molecular weight: 1,000, biomass content 50%) that has been treated by vacuum drying and dehydration, stir evenly and heat to 60°C, and weigh 53.7g of 1,6-hexamethylene diisocyanate (HDI ), add 0.04g of dibutyltin dilaurate catalyst, keep the temperature at 80°C for polymerization reaction, the reaction time is 2 hours, react until the NCO content reaches the theoretical value, and prepare the polyurethane prepolymer; 150g acetone and 50g N,N-dimethylformamide to dilute the prepolymer viscosity (avoid adding a large amount in a short time to avoid agglomeration or glue jam on the tank wall), weigh 18.65g sodium diaminobenzenesulfonate, and stir evenly for 10 minutes Finally, increase the stirring rate, slowly drop 350g water into the polyurethane prepolymer, emulsify for 10 minutes and turn to the water phase, add 1.73g diethylenetriamine and 2.05g ethylenediamine, after confirming that there is no NCO residue, keep warm Distill u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com