Adhesive composition, related article of adhesive composition, and method for preparing same

A technology of adhesives and compositions, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., to achieve the effects of good welding heat resistance, good adhesion, and low dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

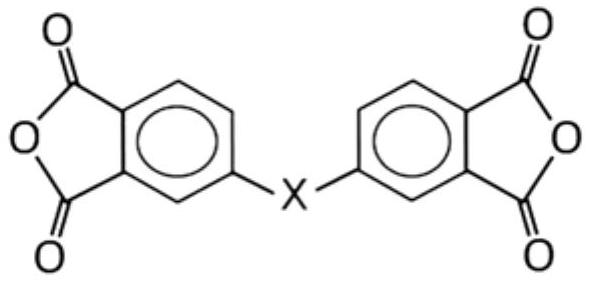

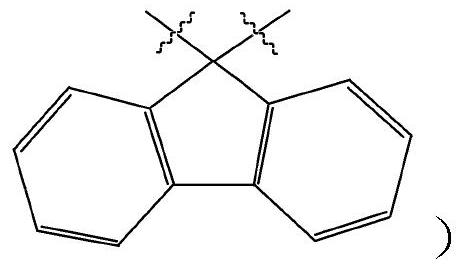

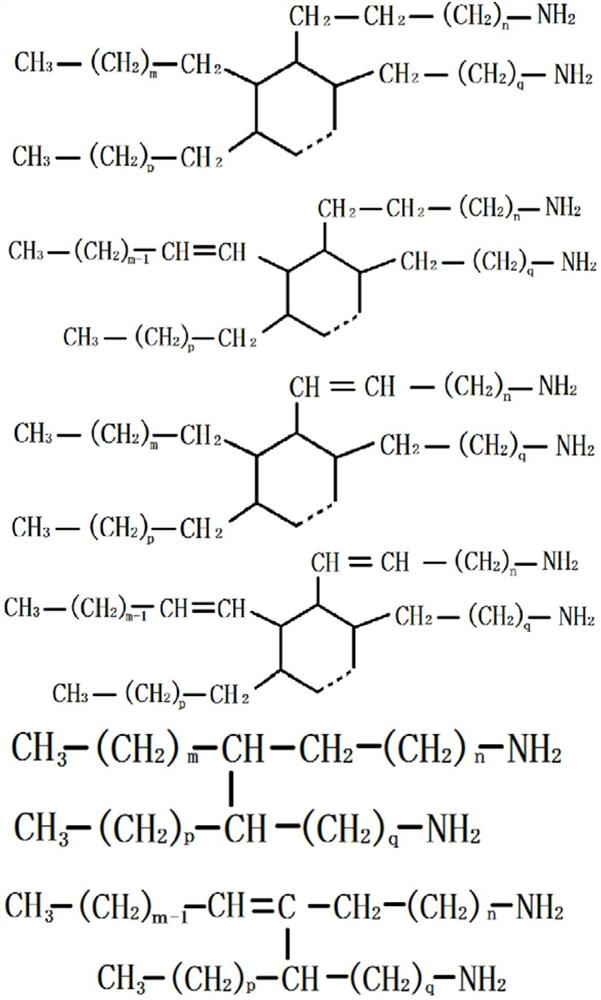

[0079] (A) Component can be manufactured by various well-known methods. As a method for producing the component (A), there are exemplified a method including the step of, preferably at a temperature of about 50°C to 120°C, more preferably at a temperature of about 80°C to 100°C, a compound containing an aromatic ring. structure and / or alicyclic structure acid dianhydride and dimer diamine, and monomer groups containing suitable other diamines and other acid anhydrides to carry out polyaddition reaction, preferably about 5 hours or less, more preferably about 3 hours or less, to obtain The process of polyaddition; preferably at a temperature of not less than 80°C and not more than 250°C, more preferably at a temperature of not less than 100°C and not more than 200°C, the resulting polyaddition is subjected to an imidization reaction (that is, a dehydration ring-closing reaction ) is preferably a step of not less than 0.5 hours and not more than 50 hours, more preferably not les...

Embodiment

[0187] Hereinafter, the present invention will be described more concretely with reference to Preparation Examples, Comparative Preparation Examples, Examples, Comparative Examples, Evaluation Examples, and Comparative Evaluation Examples, but the present invention is not limited to these Examples. In addition, in the following description, unless otherwise specified, "part" and "%" are mass basis.

[0188] In this example, the weight average molecular weight (Mw) was measured by gel permeation chromatography (GPC) under the following conditions.

[0189] (GPC measurement conditions)

[0190] Model: Product name "HLC-8320GPC" (manufactured by Tosoh Corporation)

[0191] Column: product name "TSKgel SuperHZM-M" (manufactured by Tosoh Corporation)

[0192] Developing solvent: THF

[0193] Flow: 0.35mL / min

[0194] Measuring temperature: 40°C

[0195] Detector: RI

[0196] Standard: Polystyrene

[0197] Sample preparation: 0.4% solution

preparation example 1

[0198]

[0199] Add 100.00 g of 4,4'-[propane-2,2-diylbis(1,4-phenyleneoxy)]diphthalate to a reaction vessel equipped with stirrer, water separator, thermometer and nitrogen conduit Diformic acid dianhydride (product name "BisDA-1000" (hereinafter also referred to as "BisDA"), manufactured by SABIC Inoblast Plastics Japan Co., Ltd.), 371.82 g of cyclohexanone, and the solution was heated to 60°C. Next, after slowly adding 100.82 g of C36 dimer diamine (product name "PRIAMINE 1075", manufactured by Croda Japan Co., Ltd.), 74.36 g of methylcyclohexane was added, heated to 140° C., and imidization was carried out over 3 hours. By reacting, the solution (30.0% of non-volatile matter) of a polyimide (A-1) was obtained. Moreover, the molar ratio of the acid component / amine component of this polyimide resin was 1.03, the softening point was 80 degreeC, and the weight average molecular weight was 40000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com