Chlorine-free high-base-number calcium sulfonate detergent and preparation method thereof

A technology of high basic value calcium sulfonate and detergent, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of shortening, affecting the working performance of oil products, corrosion of steel parts, etc., and achieving good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

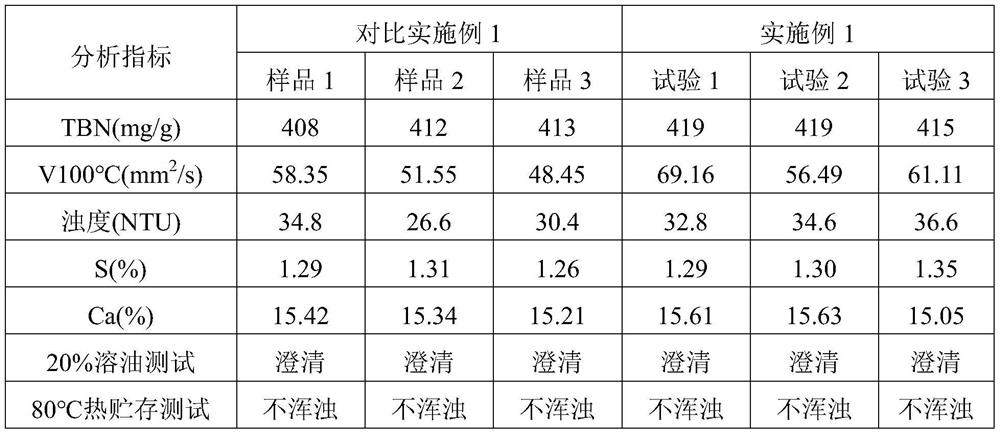

Embodiment 1

[0025] Add 40.4 parts of toluene, 0.6 parts of organic amine, 20 parts of base oil 150SN, and 2.4 parts of calcium oxide into the reactor at one time, raise the temperature of the reactor to 43°C, add 13 parts of alkylbenzenesulfonic acid, and add the acid for 55 minutes. After the acid was finished, the temperature of the reaction kettle was controlled at 55°C for 50 minutes. After the constant temperature is completed, the temperature of the reactor is lowered to 48°C, and 13.6 parts of the remaining calcium oxide are added to the reactor in 6 times, and the amount of carbon dioxide is fed in portions to match the amount of calcium oxide. After feeding carbon dioxide, raise the temperature of the reactor to 150°C, distill under reduced pressure, remove all solvents, depressurize until the flash point is qualified, stop the decompression, add an appropriate amount of diatomite filter aid for pressure filtration, and obtain chlorine-free high alkali value sulfonic acid Calcium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com