Battery runner sealing structure and application thereof

A sealing structure and flow channel technology, applied in the field of energy storage, can solve the problems of liquid leakage, resistance drop and leakage current, etc., and achieve the effect of increasing contact area, saving output consumption, and long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

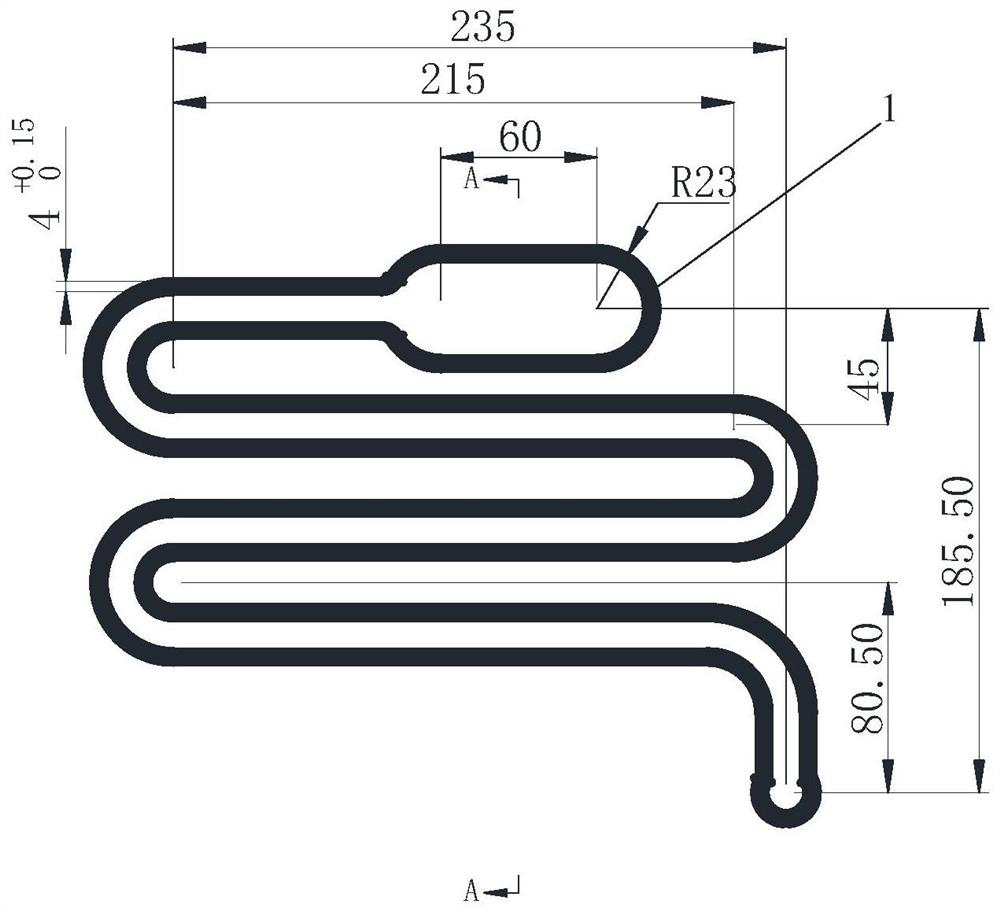

[0043] This embodiment proposes a battery flow channel sealing structure, which is to open a flow channel on the battery plate frame and seal it; a unit battery is surrounded by an upper plate frame 2 and a lower plate frame 3 that are buckled together (see Figure 7 and Figure 8 ), a serpentine flow channel 4 is provided on the lower plate frame, and the serpentine flow channel 4 is sealed by a "7"-shaped sealing ring 1, see figure 2 , image 3 and Figure 4 : the cross section of the sealing ring is a right angle "7", the top of the "7" is in contact with one side of the upper frame, and the bottom of the "7" is in contact with the side of the lower frame where the flow channel is opened.

[0044] see Figure 6 , the serpentine flow channel 4 includes an oblong liquid inlet 5, and one end of the long axis of the liquid inlet 5 is connected to the serpentine flow channel 4 bent back and forth, and the bent part is arc-shaped; the back and forth bend The folded channel h...

Embodiment 2

[0073] This embodiment proposes a battery flow channel sealing structure, which is to open a flow channel on the battery plate frame and seal it; a unit battery is surrounded by an upper plate frame 2 and a lower plate frame 3 that are buckled together. A serpentine flow channel 4 is provided on the plate frame, and the serpentine flow channel 4 is sealed by a "7"-shaped sealing ring 1: the cross section of the sealing ring is a right-angled "7" shape, and the top of the "7" shape is in line with the One side of the upper frame is in contact, and the bottom of the "7" shape is in contact with the side of the lower frame on which the flow channel is opened.

[0074] The serpentine flow channel includes an elliptical shared flow channel (multiple unit cells are assembled, the liquid inlet 5 and the shared flow channel are at the same position), and one end of the long axis of the ellipse is connected to the flow channel bent back and forth, The bent portion is arc-shaped; the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bump height | aaaaa | aaaaa |

| Overall width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com