Preparation method and application of resorcinol formaldehyde resin-based hard carbon material

A resorcinol-formaldehyde resin and resorcinol technology, which is applied in the preparation of resorcinol-formaldehyde resin-based hard carbon materials and the application field of sodium-ion battery negative electrode materials, can solve the problem of low coulombic efficiency and carbon residue rate Low-level problems, to achieve the effect of simple equipment, high activity, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

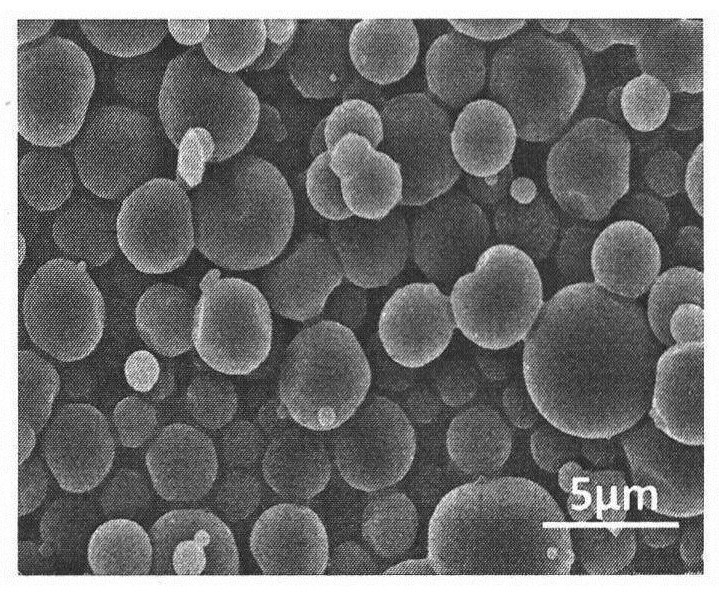

Embodiment 1

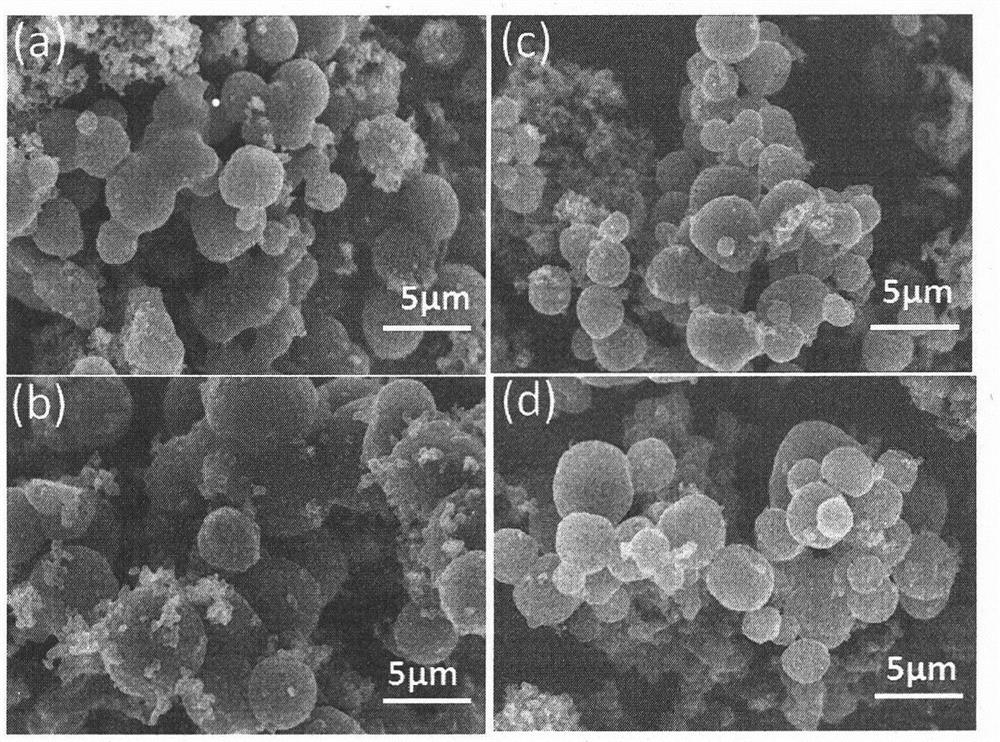

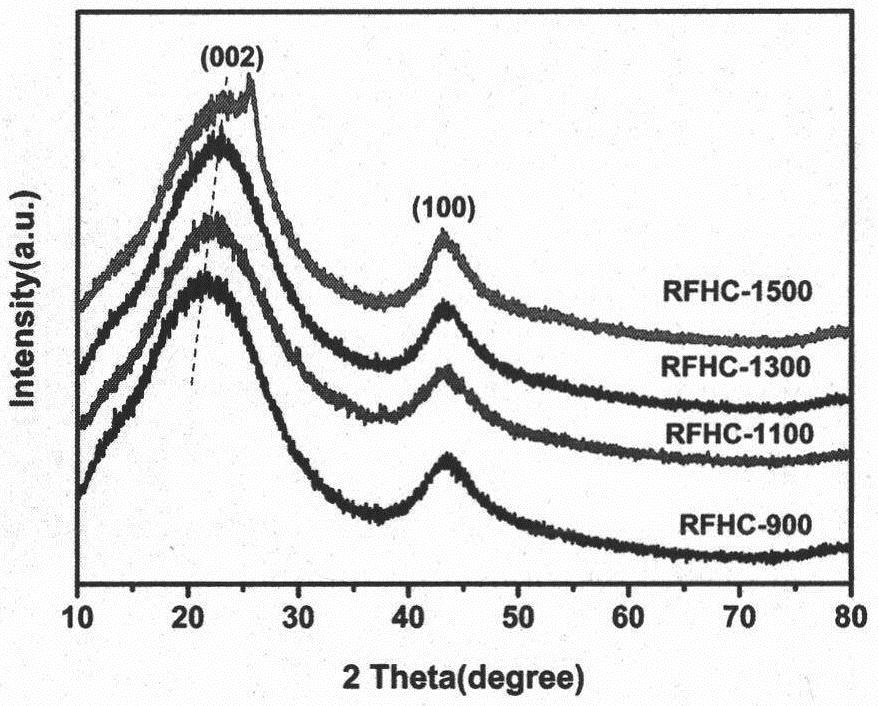

[0029] 3 g of omestically benzene, 3.3 g of water was poured into three flasks. After all of the benzene phenol dissolved, 0.2 g of ammonia water and 2.21 g (37%, 50 wt%) formaldehyde were added, and the remaining 2.21 was added after 10 minutes. G (50 wt%) formaldehyde was reacted at 40 ° C for 1 h to give a mexyphenol formaldehyde resin solution. The resulting resolved phenol formaldehyde resin solution was mixed with a certain amount of distilled water to obtain a spray liquid having a solid content of 3%. The spray liquid was sprayed and dried, and the obtained carbon material precursor was cured at 150 ° C for 24 hours, and then a resolved-benzolordehyde resin-based hard carbon negative electrode material was obtained at 900 ° C for 3 hours under the protection of nitrogen. (RFHC- 900).

Embodiment 2

[0031] 3 g of omestically benzene, 3.3 g of water was poured into three flasks. After all of the benzene phenol dissolved, 0.2 g of ammonia water and 2.21 g (37%, 50 wt%) formaldehyde were added, and the remaining 2.21 was added after 10 minutes. G (50 wt%) formaldehyde was reacted at 40 ° C for 1 h to give a mexyphenol formaldehyde resin solution. The resulting resolved phenol formaldehyde resin solution was mixed with a certain amount of distilled water to obtain a spray liquid having a solid content of 3%. The spray liquid was spray dried, and the obtained carbon material precursor was cured at 150 ° C for 24 hours, then 1100 ° C carbonized at 1100 ° C for 3 hours under the protection of nitrogen, and then obtained a neutral phenol formaldehyde resin-based hard carbon negative electrode material (RFHC- 1100).

Embodiment 3

[0033] 3 g of omestically benzene, 3.3 g of water was poured into three flasks. After all of the benzene phenol dissolved, 0.2 g of ammonia water and 2.21 g (37%, 50 wt%) formaldehyde were added, and the remaining 2.21 was added after 10 minutes. G (50 wt%) formaldehyde was reacted at 40 ° C for 1 h to give a mexyphenol formaldehyde resin solution. The resulting resolved phenol formaldehyde resin solution was mixed with a certain amount of distilled water to obtain a spray liquid having a solid content of 3%. The spray liquid was spray dried, and the obtained carbon material precursor was cured at 150 ° C for 24 hours, and then a beta-phenol formaldehyde resin-based hard carbon negative electrode material was obtained at 1300 ° C for 3 hours under the protection of nitrogen. (RFHC- 1300).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com