Method for inhibiting polymerization of ethylene in compressor equipment in production process of low-density polyethylene

A low-density polyethylene, production process technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of thinning pipe diameter, entering the pipeline, affecting the reaction, etc., to slow down the self-polymerization of ethylene And fouling phenomenon, improve production efficiency, good effect of polymerization inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

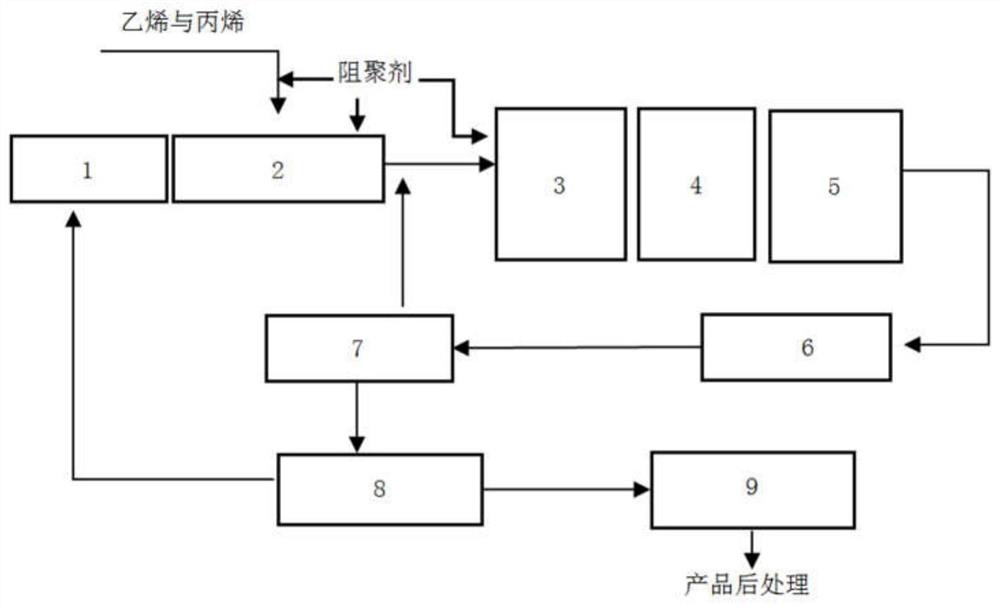

[0042] use as figure 1 The shown method and device for ethylene polymerization inhibition of the compressor in the production process of low-density polyethylene. The secondary compressor is two-stage compression; the inlet pressure of stage 3 is 24MPa, and the temperature is 38°C; the outlet pressure of stage 5 is 120MPa, and the temperature is 102°C. Inhibitor inlet pressure control is 120MPa. The feed flow rate of the reaction raw material ethylene at the inlet of the secondary compressor 3 is 48.7t / h.

[0043] When it is detected that ln(Px)>10.316-0.0511×Tx, (Px unit bar, Tx unit ℃, the same below), adjust the inhibitor flow valve, add oxygen as a polymerization inhibitor, the addition method is intermittent, and the interval time is 1 minute, the feeding speed is controlled at 0.3kg / h each time it is added. After one month of operation, it was measured that the pressure drop of the intercooler 4 of the secondary compressor units 3, 4, and 5 increased from 2.078MPa to ...

Embodiment 2

[0045] use as figure 1 The shown method and device for ethylene polymerization inhibition of the compressor in the production process of low-density polyethylene. The secondary compressor is two-stage compression; the inlet pressure of stage 3 is 24MPa, and the temperature is 38°C; the outlet pressure of stage 5 is 120MPa, and the temperature is 102°C. Inhibitor inlet pressure control is 120MPa. The feed flow rate of the reaction raw material ethylene at the inlet of the secondary compressor 3 is 48.7t / h.

[0046] When it is detected that ln(Px)>10.316-0.0511×Tx, adjust the polymerization inhibitor flow valve, add oxygen as a polymerization inhibitor, the addition method is continuous, and the oxygen flow rate is 0.3kg / h. After running for one month, the pressure drop of the intercooler 4 of the secondary compressor units 3, 4, and 5 was measured to increase from 2.098MPa to 2.291MPa, and the front and rear pressure drop increased by 0.193MPa. The device needs to be mechanic...

Embodiment 3

[0048] use as figure 1 The shown method and device for ethylene polymerization inhibition of the compressor in the production process of low-density polyethylene. The secondary compressor is two-stage compression; the inlet pressure of stage 3 is 24MPa, and the temperature is 38°C; the outlet pressure of stage 5 is 120MPa, and the temperature is 102°C. Inhibitor inlet pressure control is 120MPa. The feed flow rate of the reaction raw material ethylene at the inlet of the secondary compressor 3 is 48.7t / h.

[0049] When it is detected that ln(Px)>10.316-0.0511×Tx, adjust the polymerization inhibitor flow valve, add air as the polymerization inhibitor, the addition method is intermittent, the interval time is 1 minute, and the feeding speed is controlled at 1.2kg / h. After one month of operation, the pressure drop of the intercooler 4 of the secondary compressor units 3, 4, and 5 was measured to increase from 2.102MPa to 2.507MPa, and the front and rear pressure drop increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com