High-filling master batch for nylon and preparation method of high-filling master batch

A technology for filling masterbatch and nylon, which is applied in the field of high-filling masterbatch for nylon and its preparation, can solve the problems of dust pollution and occurrence of dust, and achieve the effects of reducing dust pollution, improving effective adhesion and improving dispersion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

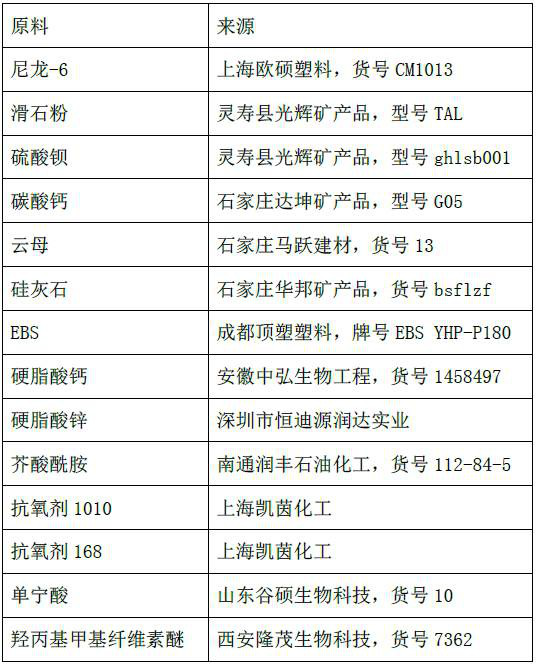

Method used

Image

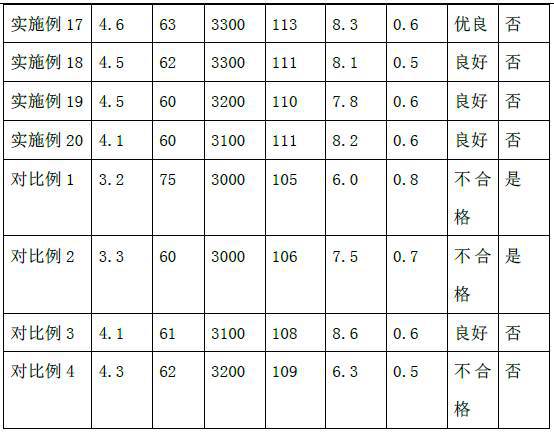

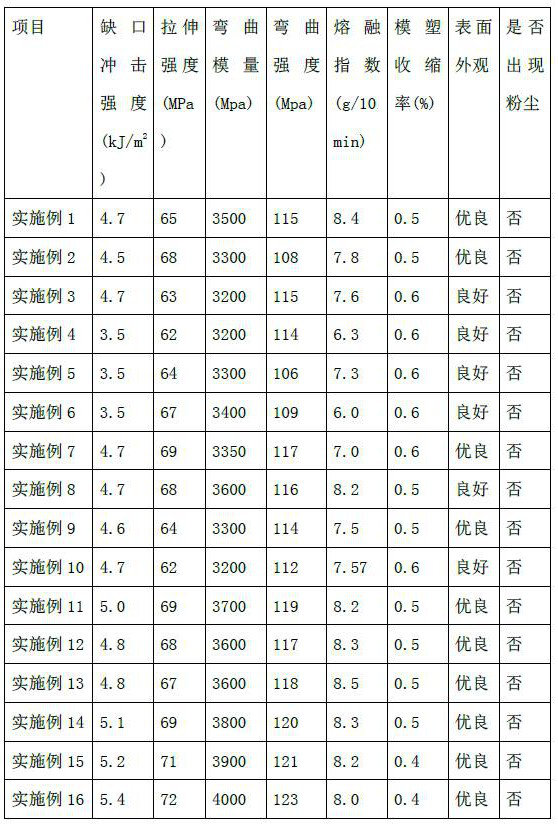

Examples

preparation example 1

[0044] According to the actual amount of talcum powder used, weigh a certain amount of talcum powder, and weigh a certain amount of tannic acid according to the weight ratio of talcum powder and tannic acid being 1:0.1. According to the weight ratio of tannic acid to water of 1:10, the weighed tannic acid was mixed with water, stirred and dissolved to obtain an aqueous solution of tannic acid. Mix the talcum powder with the tannic acid aqueous solution, then filter, and dry the collected talcum powder at 60° C. for 30 minutes to obtain the modified talcum powder, which is set aside. Among them, tannic acid is condensed tannic acid.

[0045] By adopting the above method, modified barium sulfate, modified calcium carbonate, modified mica and modified wollastonite were respectively prepared.

preparation example 2

[0047] According to the actual amount of talcum powder used, a certain amount of talcum powder was weighed, and a certain amount of tannic acid was weighed according to the weight ratio of talc powder and tannic acid being 1:0.15. According to the weight ratio of tannic acid to water of 1:15, the weighed tannic acid was mixed with water, stirred and dissolved to obtain an aqueous solution of tannic acid. Mix the talcum powder with the tannic acid aqueous solution, then filter, and dry the collected talcum powder at 70° C. for 30 minutes to obtain the modified talcum powder, which is set aside.

preparation example 3

[0049] According to the actual amount of talcum powder used, a certain amount of talcum powder was weighed, and a certain amount of tannic acid was weighed according to the weight ratio of talc powder and tannic acid being 1:0.13. According to the weight ratio of tannic acid to water of 1:13, the weighed tannic acid was mixed with water, stirred and dissolved to obtain an aqueous solution of tannic acid. Mix talcum powder and tannic acid aqueous solution, then filter, and dry the collected talcum powder at 80° C. for 30 minutes to obtain modified talcum powder, which is set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com