Biomass circulating fluidized bed oxygen-enriched combustion system and method

A circulating fluidized bed and oxygen-enriched combustion technology, which is applied in the field of circulating fluidized beds, can solve the problems of bed loss and other problems, and achieve the effects of cooling, cost reduction, low investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

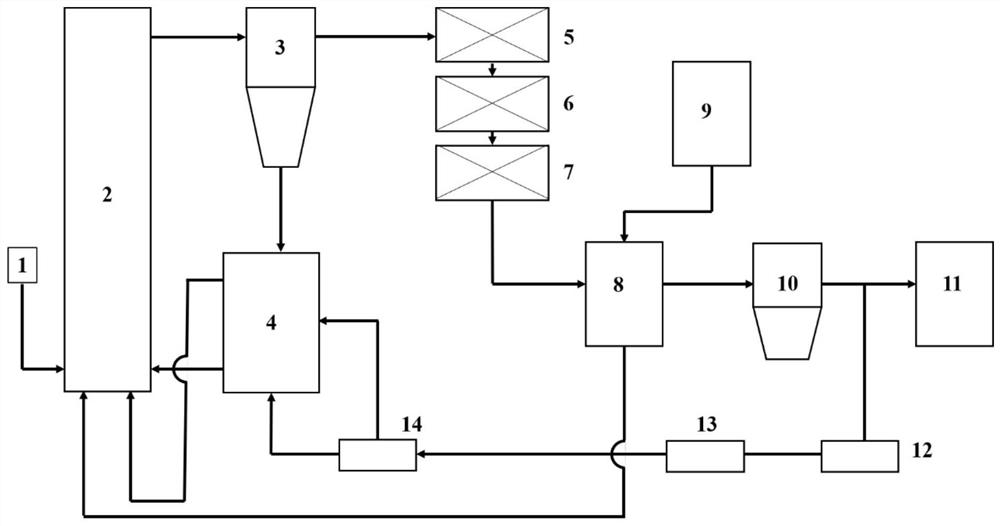

[0039] Such as figure 1 As shown, the biomass feeding unit 1 feeds the biomass raw material (specifically, corn stalks) into the circulating fluidized bed riser 2 for oxygen-enriched combustion (the oxygen concentration is 25%-28%), and the combustion temperature is 750-770 ℃, CO in the flue gas produced 2The concentration is about 80% (dry flue gas), and the water vapor content is about 20%. The generated flue gas carries the high-temperature bed material (river sand) into the high-temperature cyclone separator 3 for gas-solid separation, and the separation efficiency is 99%. The obtained high-temperature bed material enters the external oxidation heat exchanger 4, and conducts convective heat exchange with the furnace recirculation flue gas oxidation channel in the external oxidation heat exchanger 4, and the SO 2 Oxidation catalyst (specifically Fe 2 o 3 ) to 650-700°C; the separated flue gas flows through the high-temperature superheater 5, the low-temperature superheat...

Embodiment 2

[0041] Such as figure 1 As shown, the biomass feeding unit 1 feeds the biomass raw material (specifically wood chips) into the circulating fluidized bed riser 2 for oxygen-enriched combustion (the oxygen concentration is 45%-48%), and the combustion temperature is 930-950°C , CO in the flue gas produced 2 The concentration is about 80%, and the water vapor content is about 20%. The generated flue gas carries the high-temperature bed material (specifically, river sand) into the high-temperature cyclone separator 3 for gas-solid separation, and the separation efficiency is 99%. The separated high-temperature The bed material enters the external oxidation heat exchanger 4, and conducts convective heat exchange with the furnace recirculation flue gas oxidation channel in the external oxidation heat exchanger 4, and the SO 2 Oxidation catalyst (specifically Fe 2 o 3 ) to 550-640°C; the separated flue gas flows through the high-temperature superheater 5, the low-temperature super...

Embodiment 3

[0043] Such as figure 1 As shown, the biomass feeding unit 1 feeds the biomass raw material (specifically, corn stalks) into the circulating fluidized bed riser 2 for oxygen-enriched combustion (the oxygen concentration is 40%-42%), and the combustion temperature is 820-850 ℃, CO in the flue gas produced 2 The concentration is about 80% or more (dry flue gas), and the water vapor content is about 20%; the generated flue gas carries high-temperature bed material (specifically clay) into the high-temperature cyclone separator 3 for gas-solid separation, and the separation efficiency is 99% The separated high-temperature bed material enters the external oxidation heat exchanger 4, and performs convective heat exchange with the furnace recirculation flue gas oxidation channel in the external oxidation heat exchanger 4, and the SO 2 Oxidation catalyst (specifically V 2 o 5 ) to 450-460°C; the separated flue gas flows through the high-temperature superheater 5, the low-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com