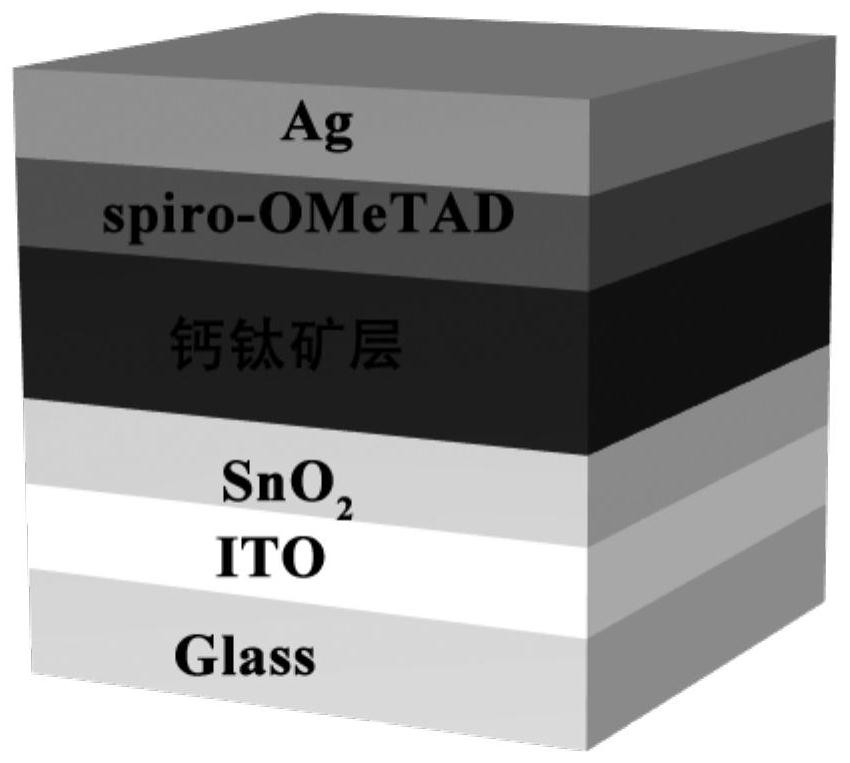

Preparation method of perovskite solar cell with perovskite layer passivated by nanofibers

A technology of solar cells and nanofibers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low efficiency and poor stability of perovskite cells, and achieve improved photoelectric conversion efficiency, improved performance, and controllable dimensions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

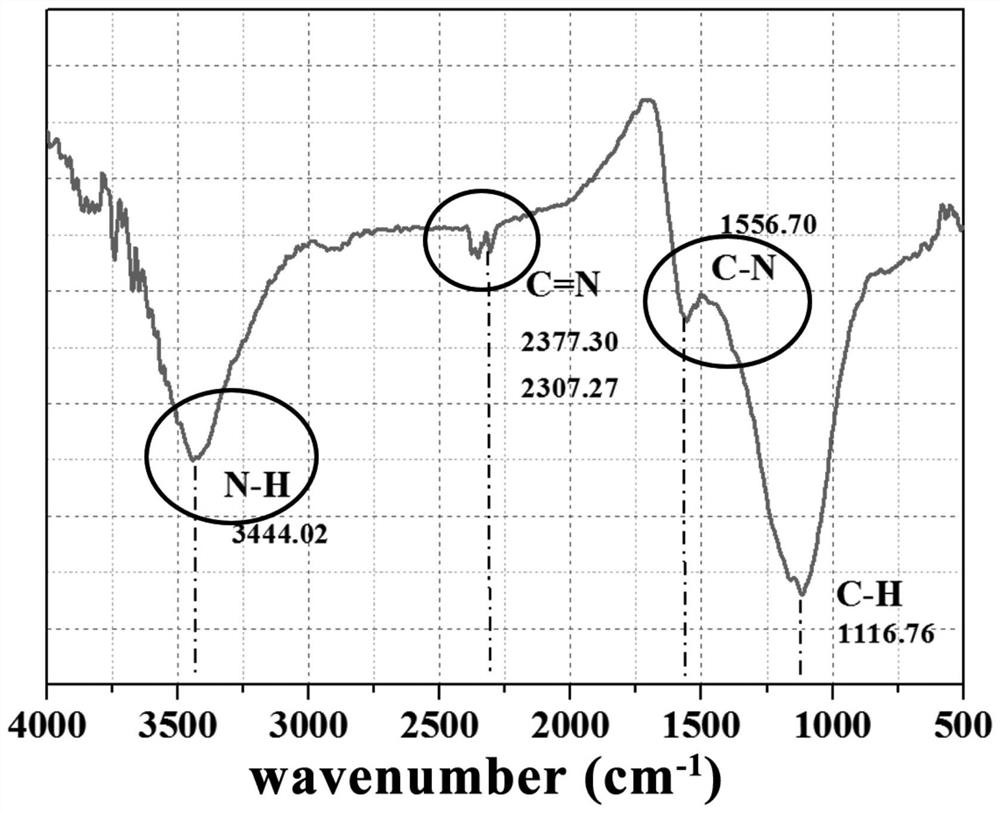

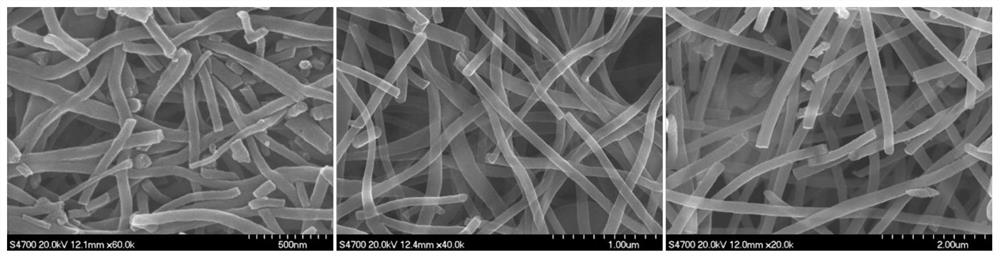

[0023] First, the nanofibers are processed into polymer nanofibers by electrospinning technology from a polyacrylonitrile / N,N-dimethylformamide solution with a mass fraction of 10 wt%. The electrospinning parameters are as follows: ①Nozzle and negative high voltage generator connection, the negative high voltage value is -5kV; ②The distance between the nozzle and the receiving plate is 15cm; ③The receiving plate is connected to the positive high voltage generator, and the positive high voltage is +10kV; ④The feeding speed is controlled by the propulsion pump, and the feeding speed is 1.0 mL·h -1 , to obtain polymer nanofibers. Then, the polymer nanofibers were kept at 240° C. for 60 minutes in an air atmosphere, then passed through nitrogen, and then heated to 800° C., kept for 60 minutes in a nitrogen atmosphere, and then cooled to obtain nanofibers. The heating and cooling rates are both 5°C per minute.

[0024] Next: (1) Conductive glass (fluorine-doped SnO 2 Conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com