Method for preparing nitrogen-doped multi-dimensional hierarchical porous carbon material adaptive to sulfur positive electrode carrier of aluminum-sulfur battery

An aluminum-sulfur battery, nitrogen-doped technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of poor infiltration between the electrolyte and the positive electrode, and low conductivity of the ionic liquid, so as to increase the sulfur load of the positive electrode , Promote ion migration, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

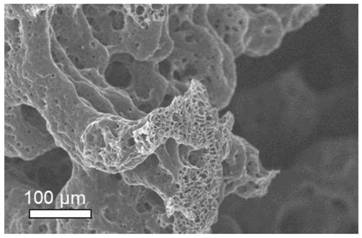

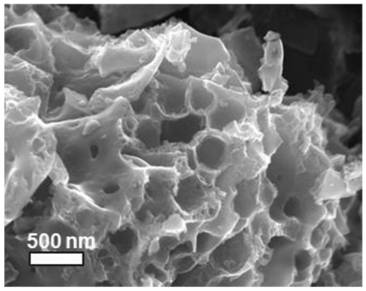

[0036] A method for preparing a nitrogen-doped three-dimensional hierarchical porous carbon material suitable for the sulfur positive electrode carrier of an aluminum-sulfur battery in this embodiment is characterized in that the preparation is carried out according to the following steps:

[0037] (1) Preparation of polymer precursor

[0038] Put 1.98g of diaminodiphenylmethane, 0.75g of paraformaldehyde, 8.91g of zinc nitrate hexahydrate and 20mL of N-methylpyrrolidone in a high-pressure reaction bottle, and keep stirring at 100°C for 4h under the protection of argon, then cool down and stand still to obtain A homogeneous solution of high nitrogen content polymer precursor and zinc salt.

[0039] (2) Preparation of nitrogen-doped three-dimensional hierarchical porous carbon materials

[0040] Take an appropriate amount of precursor solution in the ark and place it in a tube furnace for sintering. Adjust the air pressure in the tube furnace to always keep it at 0.1atm, keep...

Embodiment 2

[0051] Others are as in Example 1.

[0052] The difference is that in step (1), 1 g of zinc chloride is added during the preparation of the polymer precursor.

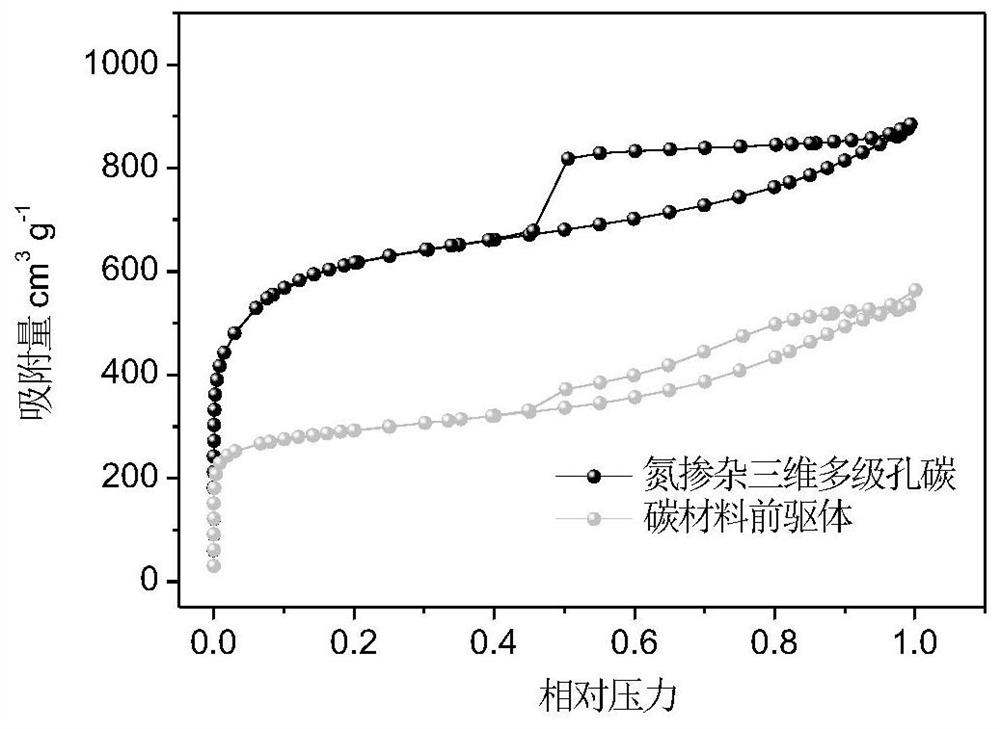

[0053] The pore structure of the prepared nitrogen-doped three-dimensional hierarchical porous carbon has been better improved, and the pore volume is higher than that in step (2) of Example 1, which is 0.88 cm 3 g -1 . Al–S batteries based on this material exhibit good long-cycle performance.

Embodiment 3

[0055] Others are as in Example 1. The difference is that in step (1), 3.48g of iron nitrate is added during the preparation of the polymer precursor, and the iron element in the prepared nitrogen-doped three-dimensional hierarchical porous carbon is uniformly distributed and the content is 6.94wt.%. Aluminum sulfur battery at 0.2A g -1 Under constant current charge and discharge, the average discharge voltage is increased from 0.6V to 0.75V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com