Processing method of low-GI high-activity coarse cereal composite instant nutrition powder

A processing method and high-activity technology, which is applied in the field of food processing, can solve the problems of high glycemic index, poor instant solubility, and large loss of nutritional active substances in products, and achieve the effects of improving the health level of residents, delicate taste, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

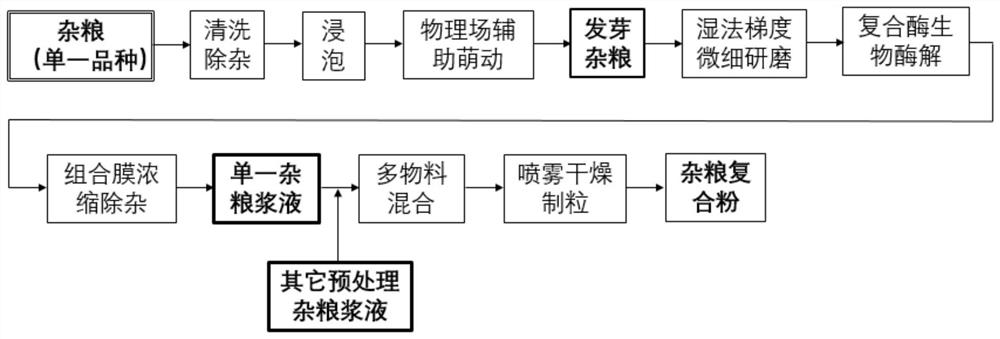

Method used

Image

Examples

Embodiment 1

[0027] Step 1. Cleaning and removing impurities: wash the miscellaneous grain raw materials with water to remove water-soluble and small particle impurities, so that they can reach food grade;

[0028] Step 2. Soaking: Soak the cleaned miscellaneous grain raw materials at 25°C for 6 hours to make the raw materials absorb water and swell moderately. After soaking, drain the excess water completely. The ratio of solid grains to water is 1 : 10, the moisture content of miscellaneous grain raw material is 46% after regulation;

[0029] Step 3. Physical field-assisted germination: The soaked and swollen miscellaneous grain raw materials are placed in a constant temperature and humidity environment with a magnetic field and ultraviolet light for germination to obtain germinated miscellaneous grains. The germination temperature is 25°C, and the germination time is 36h. The intensity is 4mT, and the ultraviolet lamp is irradiated for 5 minutes every 4 hours, and the germination length...

Embodiment 2

[0037] Step 1. Cleaning and removing impurities: wash the miscellaneous grain raw materials with water to remove water-soluble and small particle impurities, so that they can reach food grade;

[0038] Step 2. Soaking: Soak the cleaned miscellaneous grain raw materials at 20°C for 10 hours to make the raw materials absorb water and swell moderately. After soaking, drain off the excess water completely. The ratio of solid grains to water is 1 : 5, the moisture content of miscellaneous grain raw material is 35% after regulation;

[0039] Step 3. Physical field-assisted germination: The soaked and swollen miscellaneous grain raw materials are placed in a constant temperature and humidity environment with a magnetic field and ultraviolet light for germination to obtain germinated miscellaneous grains. The germination temperature is 20°C, the germination time is 48h, and the magnetic field The intensity is 6mT, and the ultraviolet lamp is irradiated for 10min every 4h, and the germ...

Embodiment 3

[0047] Step 1. Cleaning and removing impurities: wash the miscellaneous grain raw materials with water to remove water-soluble and small particle impurities, so that they can reach food grade;

[0048] Step 2. Soaking: Soak the cleaned miscellaneous grain raw materials at 35°C for 6 hours to make the raw materials absorb water and swell moderately. After soaking, drain the excess water completely. The ratio of solid grains to water is 1 : 8, the moisture content of miscellaneous grain raw material is 40% after regulation;

[0049] Step 3. Physical field-assisted germination: The soaked and swollen miscellaneous grain raw materials are placed in a constant temperature and humidity environment with a magnetic field and ultraviolet light for germination to obtain germinated miscellaneous grains. The germination temperature is 30°C, the germination time is 20h, and the magnetic field The intensity is 8mT, and the ultraviolet lamp is irradiated for 15min every 4h, and the germinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com