Energy-saving vibration group device system

An energy-saving and integrated technology, applied in chemical instruments and methods, membranes, biological water/sewage treatment, etc., can solve problems such as high failure rate, increased maintenance cost, troublesome control system, etc., and achieves high precision and installation. Easy maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

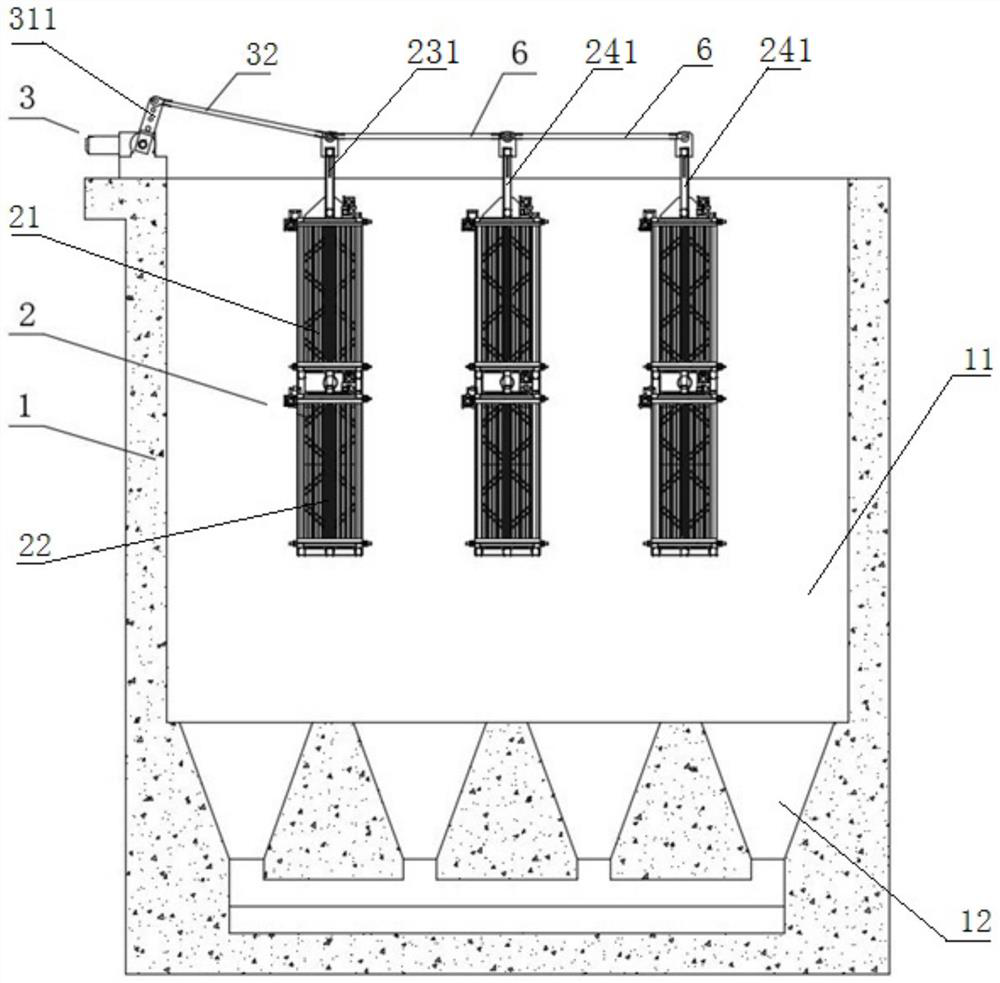

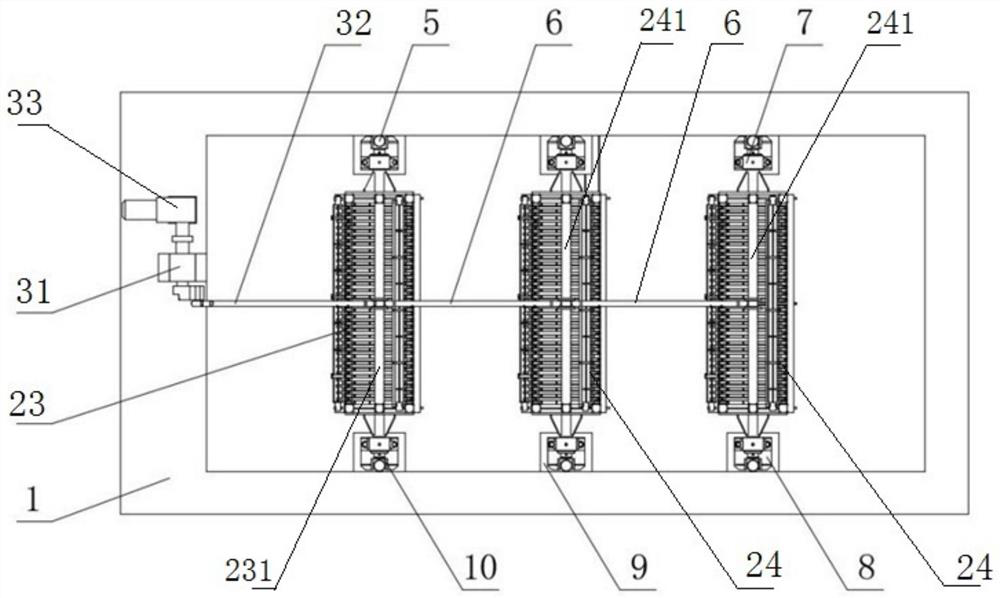

[0084] Embodiment 1 (in municipal sewage, energy saving 80%):

[0085] A municipal sewage treatment plant project adopts the MBR process, and the solid-liquid separation part adopts a swing-type vibration assembly system. The distance r from the central axis of the double-layer assembly to the upper and lower ends of the component is 0.25m, the swing angle is 20°, and the swing frequency is f 0.5Hz. The total height of the membrane tank is 5.5m, the concentration of the mixed solution entering the membrane tank at the front end is 4-6g / L, and the sludge concentration of the membrane tank is 12g / L. The pressure difference changes after 10 months of operation are as follows: figure 1 As shown, the flux is maintained at 24-30LMH, and the energy consumption of the membrane cell is 0.015KWh / m 3 , compared to the energy consumption of aerated MBR 0.1KWh / m 3 , saving 85%.

Embodiment 2

[0086] Embodiment 2 (in anaerobic environment, enhance pollution resistance):

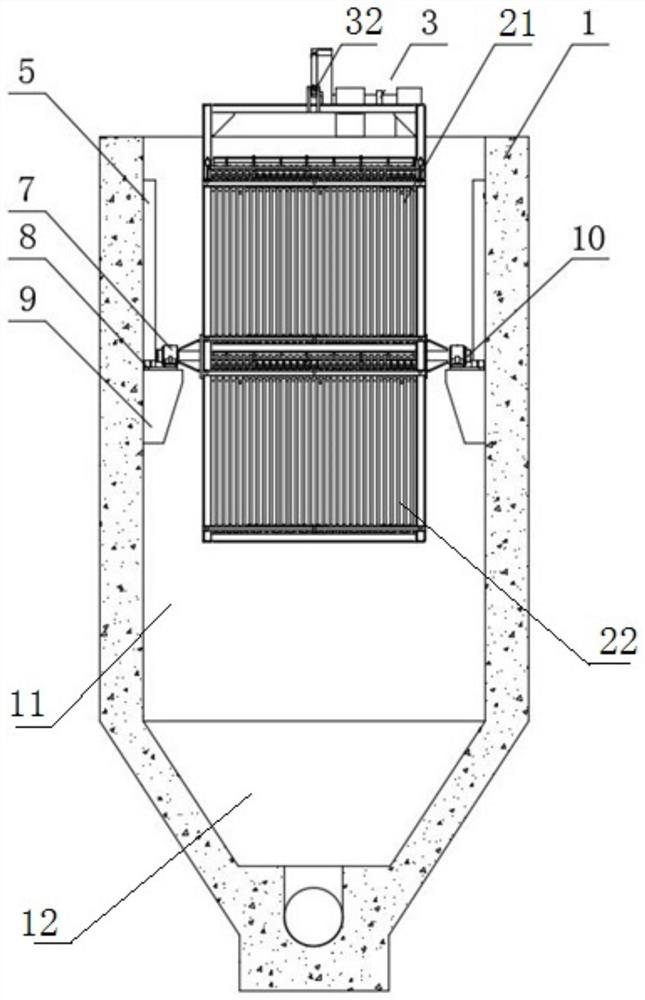

[0087] In an anaerobic MBR project, membrane fouling is controlled in an anaerobic environment, and air aeration is not available. It is difficult and costly to use inert gas and methane for aeration. The use of mechanical movement to control membrane fouling is more suitable for use in anaerobic MBR. By adopting this form of pollution control means, the membrane is used for solid-liquid separation instead of the three-phase separator. The membrane tank adopts this kind of membrane tank structure, the total height of the membrane tank is 4.5m, the frequency of the driving system is 0.7Hz, and the front end enters the membrane tank The concentration of the mixed liquid is 10000mg / L, the sludge concentration in the membrane separation zone is 4000mg / L, and the sludge concentration in the lower settlement zone is 25000mg / L. 100% of the anaerobic sludge in the membrane pool is retained, effectively ret...

Embodiment 3

[0088] Embodiment 3 (in solid-liquid separation, enhance anti-pollution):

[0089] In the coagulation-sedimentation-ultrafiltration process, by adopting this method to control ultrafiltration membrane fouling, the total height of the membrane pool is 5.0m, the frequency of the drive system is 0.5Hz, the SS content of the front end entering the membrane pool is 100mg / L, and the upper end The sludge concentration in the membrane separation area is 50mg / L, and the sludge concentration in the lower settlement area is 1200mg / L. The stable operating flux of the membrane system is 30-45LMH, and the online maintenance cleaning cycle is two weeks. After adopting this kind of vibrating membrane separation system, the turbidity of the membrane pool can be as high as 200NTU, and the pollution cleaning cycle of the system is doubled.

[0090] The above examples fully prove that the following effects can be achieved by adopting this kind of oscillating structure:

[0091] The swing vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com