Friction material and preparation method thereof

A technology of friction material and mesh cloth, which is applied in the field of materials, can solve the problems of material waste, achieve the effects of protecting the environment, not easy to delaminate, and increasing the shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method of preparing a friction material, comprising the steps of:

[0034] (1) According to the weight of the copper wire, the weight of the short cotton is 20%, and the weight of glass is 65% compared to 5% of the viscosity weight, and prepared into a core yarn;

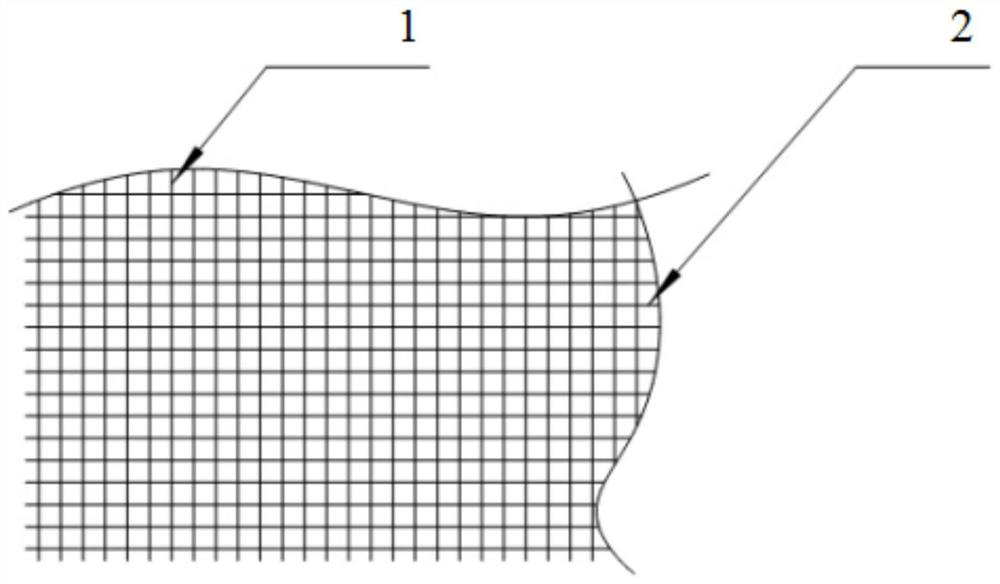

[0035] (2) The woven woven fabric is made from the woven machine to obtain a net gauze; wherein the wire density contains 15 wires per 10 cm; the latitude density is 15 wires within 10 cm;

[0036] (3) Immerse the mesh cloth into a phenol resin having a solid content of 85%, dried under 80 ° C for 5 h, and the mesh cloth increases weight, and the resin mesh is obtained.

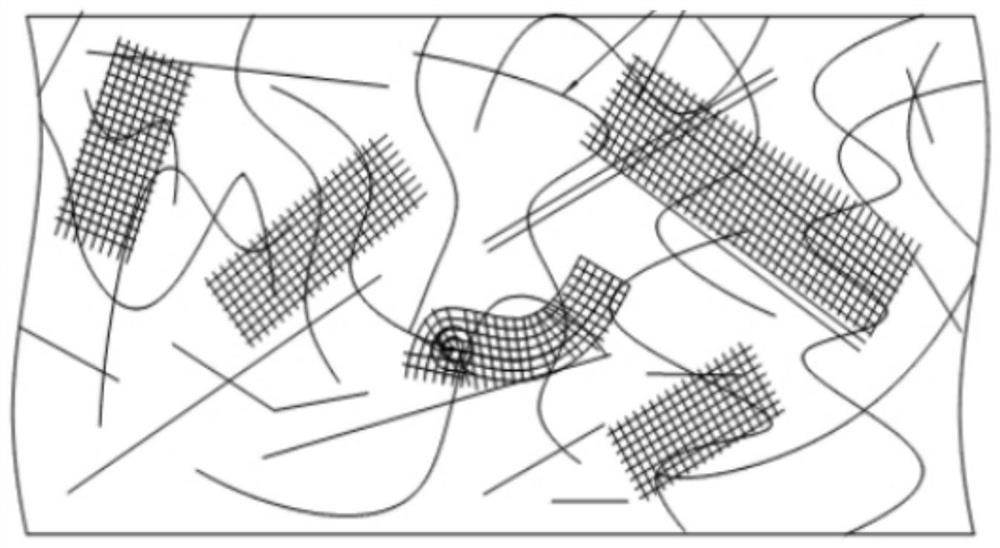

[0037] (4) Cut the resin grid to the size of about 20 mmX50 mm and placed in the mold, and pressulate it under 120 ° C, 12 MPa, and the exhaust gas is 3 times, the total pressure is 10 min, and the semi-finished product;

[0038] (5) The semi-finished product continues to curing 1 h at 120 ° C, and then take out the in...

Embodiment 2

[0040] This embodiment provides a method of preparing a friction material, comprising the steps of:

[0041] (1) According to the weight of the copper wire, the weight of the short cotton line accounts for 24%, and the weight of the glass is 60% and the viscose weight is 6%, prepared into the core yarn;

[0042] (2) The woven woven fabric is obtained by a knitting machine to obtain a grid (therein, wherein the linear density is 30-wire 30; the weft density is 30 wires per 10 cm;

[0043] (3) Immerse the mesh cloth into a solid content of 85% epoxy resin, drying under 110 ° C for 2 h after impregnation, and the weight of the mesh is increased by 80%, and the resin mesh is obtained.

[0044] (4) Cut the resin grid to a size of about 25 mm × 150 mm and placed in the mold, and press the pressure under 170 ° C, 23 MPa, and the exhaust gas is 10 times, the total pressure is 12 minutes, and the half finished product ;

[0045] (5) The semi-finished product continues to curing 5 h at 180 ...

Embodiment 3

[0047] This embodiment provides a method of preparing a friction material, comprising the steps of:

[0048] (1) According to the weight of the copper wire, the weight of the short cotton line accounts for 15%, and the glass fiber is 73% and the viscose weight is 4%, and the brain core is prepared;

[0049] (2) The woven woven fabric is made from the woven machine to obtain a net grid; wherein the lack density is 23 cm, and the latitude density is 23 cm.

[0050] (3) Immerse the mesh cloth into a solid content of 60% epoxy resin, drying under 110 ° C for 3 h after impregnation, and the mesh cloth weight is 60%, and the resin mesh is obtained.

[0051] (4) Charting the resin grid to a size of about 40 mm × 40 mm and placed in a mold, under pressure under 150 ° C, 18 MPa, and the exhaust gas is 15 times, the total pressure is 11 min, and the half finished product ;

[0052] (5) The semi-finished product continues to curing 12 h at 155 ° C, and then take out the inside and outside of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com