Nitrogen-sulfur co-doped cellulose-based fluorescent carbon dots and application thereof

A cellulosic and fluorescent carbon dot technology, applied in the field of nanomaterials, can solve the problems of expensive precursor raw materials, complicated and time-consuming operation process, expensive equipment, etc., and achieve the effects of good water solubility, stable fluorescence and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]This example provides a nitrogen-sulfur co-doped cellulose-based fluorescent carbon dot, which is prepared by the following method:

[0046] Put 0.5g of cellulose powder, 0.15g of sodium thiosulfate powder and 0.5mL of ethylenediamine solution (analytical grade) into a polytetrafluoroethylene reactor, while adding 10ml of ultrapure water as a solvent. Put the reaction kettle in a constant temperature oven at 180°C, react for 72 hours, centrifuge to obtain a brown carbon dot reaction solution, dialyze the reaction solution with a 500Da dialysis tube for 72 hours, and then freeze the dialyzed solution with a lyophilizer to finally obtain nitrogen Sulfur-co-doped cellulose-based fluorescent carbon dots.

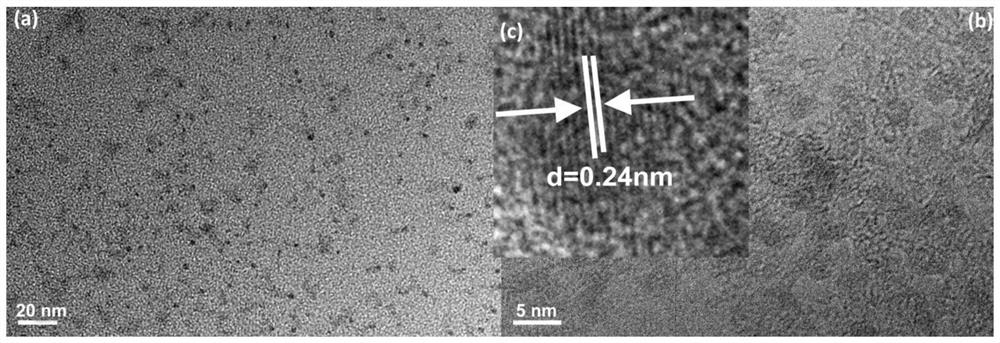

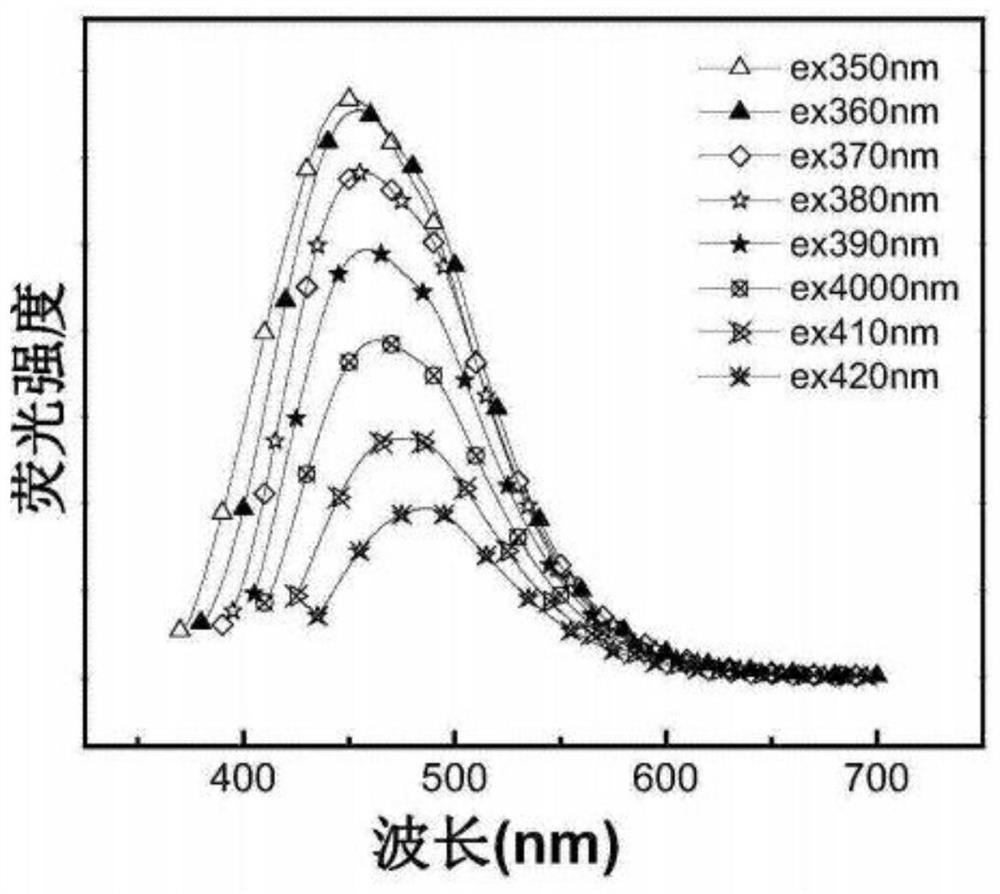

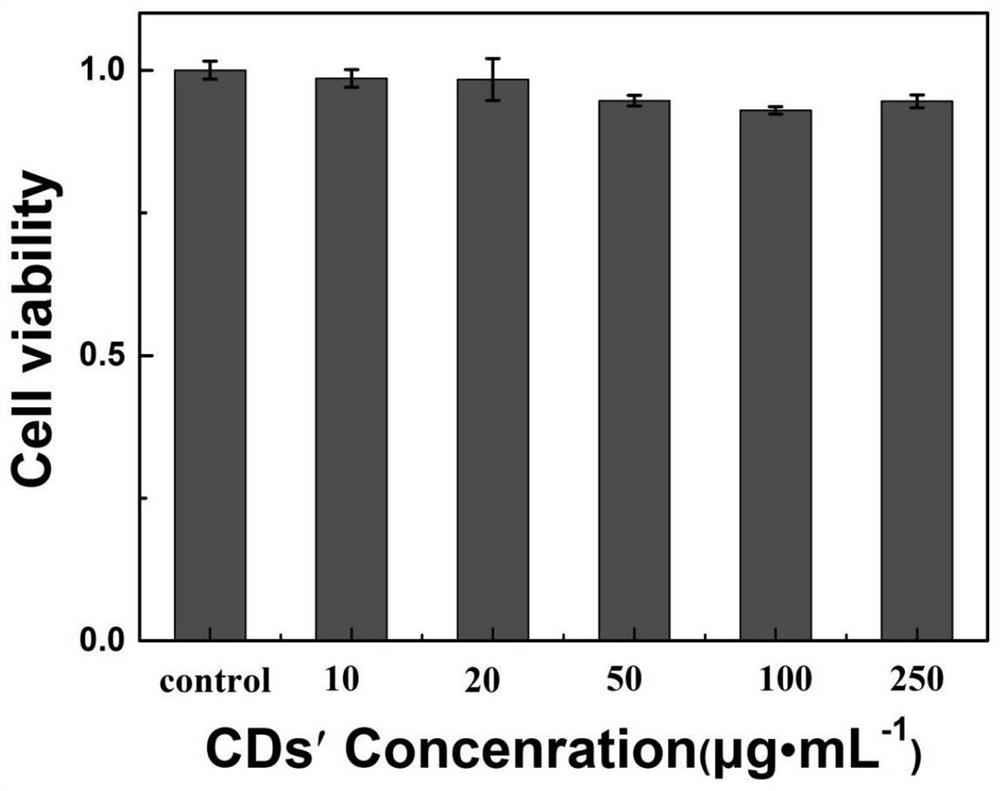

[0047] In order to further illustrate the technical effects of the present invention, the applicant also tested the nanoparticle size, fluorescent properties and cytotoxicity of the nitrogen-sulfur co-doped cellulose-based fluorescent carbon dots obtained in Example 1, spe...

Embodiment 2

[0055] This example provides a nitrogen-sulfur co-doped cellulose-based fluorescent carbon dot, which is prepared by the following method:

[0056] Put 2g of cellulose powder, 3g of sodium thiosulfate powder and 0.7mL of ethylenediamine solution (analytical grade) into a polytetrafluoroethylene reactor, while adding 40ml of ultrapure water as a solvent. Put the reaction kettle in a constant temperature oven at 200°C, react for 80 hours, and centrifuge to obtain a brown carbon dot reaction solution. Dialyze the reaction solution with a 800Da dialysis tube for 82 hours, and then freeze-dry the dialyzed solution to finally obtain nitrogen-sulfur co-doped Cellulose-based fluorescent carbon dot material.

Embodiment 3

[0058] This example provides a nitrogen-sulfur co-doped cellulose-based fluorescent carbon dot, which is prepared by the following method:

[0059] Put 4g of cellulose powder, 3.5g of sodium thiosulfate powder and 0.8mL of ethylenediamine solution (analytical grade) into a polytetrafluoroethylene reactor, and add 60ml of ultrapure water as a solvent. Put the reaction kettle in a constant temperature oven at 150°C, react for 70 hours, and centrifuge to obtain a brown carbon dot reaction solution. Dialyze the reaction solution with a 900Da dialysis tube for 80 hours, and then freeze-dry the dialyzed solution to finally obtain nitrogen-sulfur co-doped Cellulose-based fluorescent carbon dot material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com