Preparation method of starch nanofiber membrane and starch nanofiber membrane

A starch nano-fiber film technology, which is applied in fiber treatment, textiles, papermaking, non-woven fabrics, etc., can solve the problems of poor direct film-forming property, affecting the performance of the film, and the film does not have a nanoscale, so that the preparation process is simple, Good direct film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

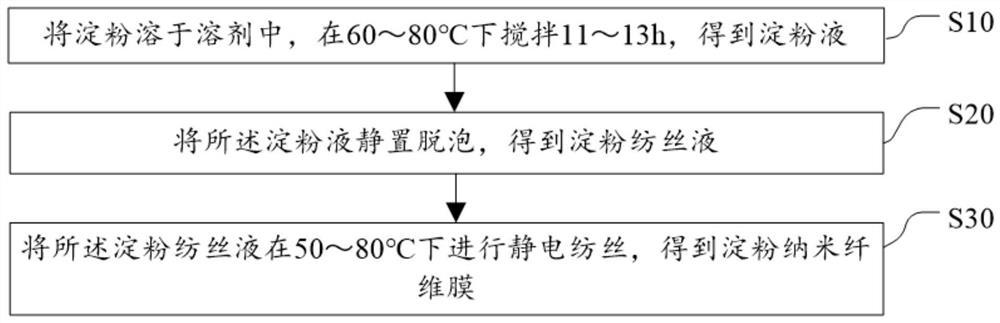

[0038] see figure 1 , the preparation method of starch nanofiber film, comprises the following steps:

[0039] S10, dissolving the starch in a solvent, stirring at 60-80° C. for 11-13 hours to obtain a starch liquid;

[0040] For the kind of solvent, the present invention does not limit, and preferably, solvent is the aqueous solution of dimethyl sulfoxide, and dimethyl sulfoxide (DMSO) is a kind of sulfur-containing organic compound, and molecular formula is (CH 3 ) 2 SO, a colorless, odorless, transparent liquid at room temperature, is a hygroscopic flammable liquid. It has the characteristics of high polarity, high boiling point, good thermal stability, aprotic, and water miscibility. It can be dissolved in most organic substances such as ethanol, propanol, benzene and chloroform, and is known as a "universal solvent". Using an aqueous solution of dimethyl sulfoxide can quickly dissolve starch, and in addition, it can also quickly volatilize during electrospinning, so th...

Embodiment 1

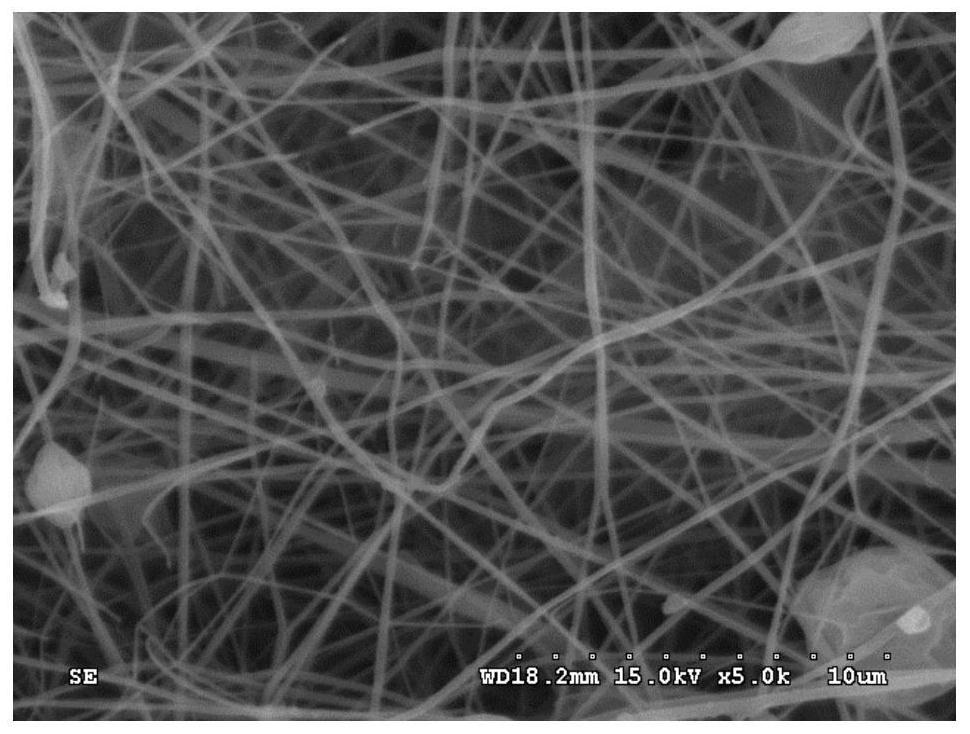

[0057] Starch was added to an aqueous solution of dimethyl sulfoxide with a volume concentration of 95%, and magnetically stirred at 70°C for 12 hours to obtain a uniform and transparent starch liquid with a mass fraction of 20%, and the starch liquid was left standing at room temperature for defoaming. Obtain starch spinning solution. Add the starch spinning solution into a 10mL medical syringe, set the ambient temperature to 60°C at a propulsion speed of 1ml / L, the spinning voltage to 20kV, and the distance between the needle and the collection device to be 15cm to perform electrospinning, electrospinning After a period of time, a starch nanofibrous film is obtained on the collecting device.

Embodiment 2

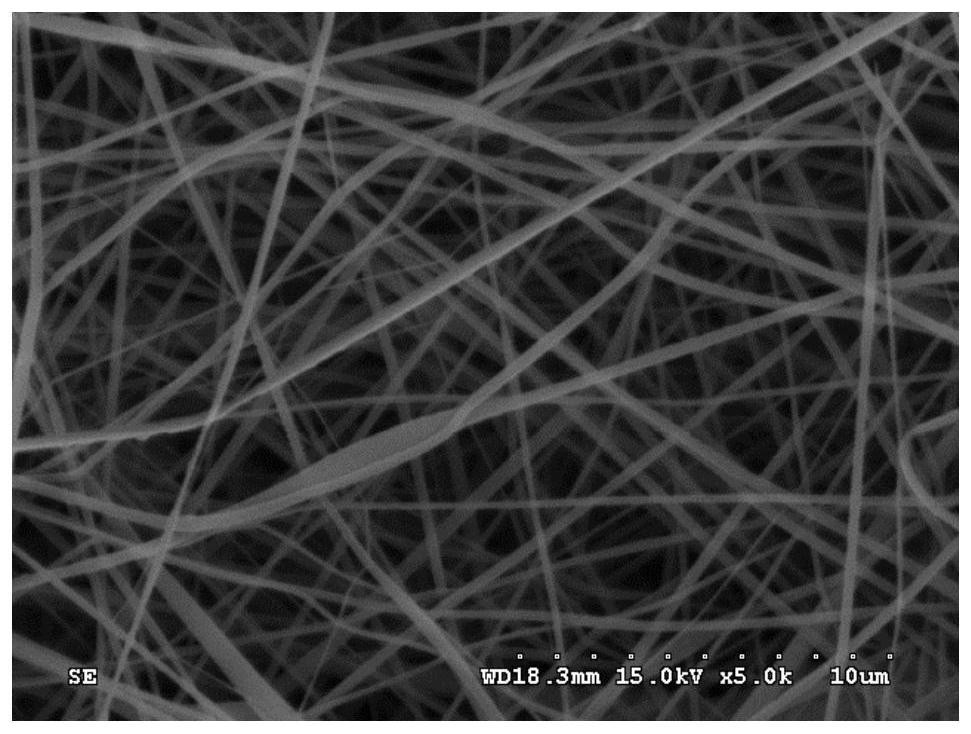

[0059] Starch was added into an aqueous solution of dimethyl sulfoxide with a volume concentration of 95%, and magnetically stirred at 70°C for 12 hours to obtain a uniform and transparent starch liquid with a mass fraction of 22.5%, and the starch liquid was left to defoam at room temperature. Obtain starch spinning solution. Add the starch spinning solution into a 10mL medical syringe, set the ambient temperature to 60°C at a propulsion speed of 1ml / L, the spinning voltage to 20kV, and the distance between the needle and the collection device to be 15cm to perform electrospinning, electrospinning After a period of time, a starch nanofibrous film is obtained on the collecting device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com