A temperature control structure suitable for subgrade and slope engineering in permafrost regions

A technology for permafrost areas and roadbeds, applied in roads, roads, climate change adaptation and other directions, can solve problems such as uneven settlement of pavement, failure of ventilation pipes, failure of engineering measures, etc. Uniform and improve the effect of engineering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

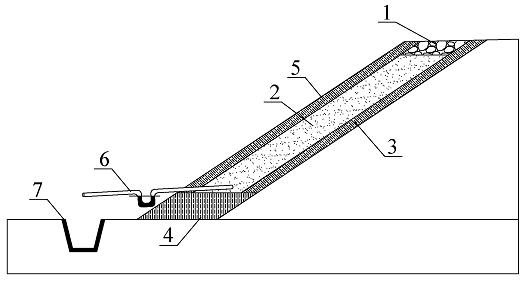

[0024] Such as figure 1 As shown, a temperature control structure suitable for subgrade and slope engineering in permafrost regions, the structure includes a pebble layer 1, a diatomite layer 2, an inner water-resisting layer 3, a bottom layer 4, an outer water-resisting layer 5 and Drain pipe 6.

[0025] The bottom surface layer 4 is arranged on the subgrade in the permafrost region, and the bottom surface layer 4 is provided with an inner water-resisting layer 3 and an outer water-resisting layer 5; the inner water-resisting layer 3 is in contact with the slope soil of the subgrade in the permafrost region; The space formed by the connection of the water layer 3, the bottom surface layer 4 and the outer waterproof layer 5 is filled with a diatomite layer 2, and the top surface of the diatomite layer 2 is provided with a pebble layer 1; a part of the drain pipe 6 passes through the outer The water-resisting layer 5 is obliquely inserted into the bottom of the diatomite layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com