Multi-port grid-shaped modularized multi-level direct-current converter

A DC converter, multi-level technology, applied in the direction of converting DC power input to DC power output, adjusting electrical variables, output power conversion devices, etc., can solve the problem of uneven stress distribution of switching devices, uneven device stress, voltage Inability to control independently and other problems to achieve the effect of standardized production and assembly, flexible expansion of the number of ports and power capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

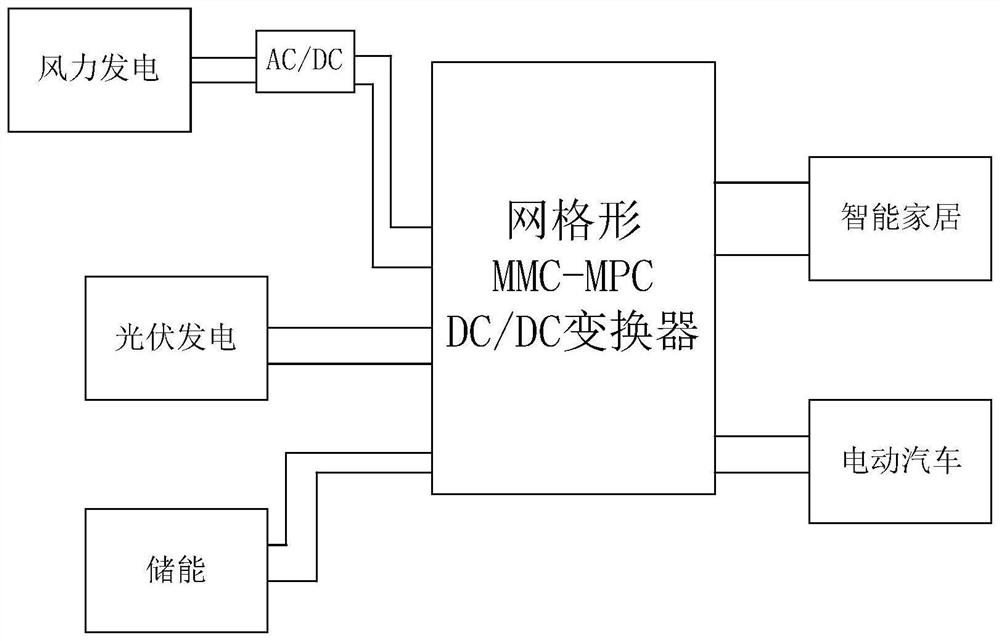

[0023] The application scenarios of a multi-port grid-shaped modular multi-level DC converter provided by the present invention are as follows: figure 1 As shown, it can be new energy fields, household appliances and so on. Application scenarios such as: wind power generation, photovoltaic power generation, smart home, electric vehicles, etc.

[0024] It can be understood that the current new energy business continues to develop. Wind power and photovoltaic power generation are renewable new energy sources. However, new energy power generation has intermittent and fluctuating shortcomings. Using the charging and discharging characteristics of energy storage devices such as batteries can play a role in new energy power generation. The function of peak shaving and valley filling enables the system to output reliable and stable power as a whole and improves power quality. In today's household appliances and IT products, most of them work in the DC state, such as DC inverter air ...

Embodiment 2

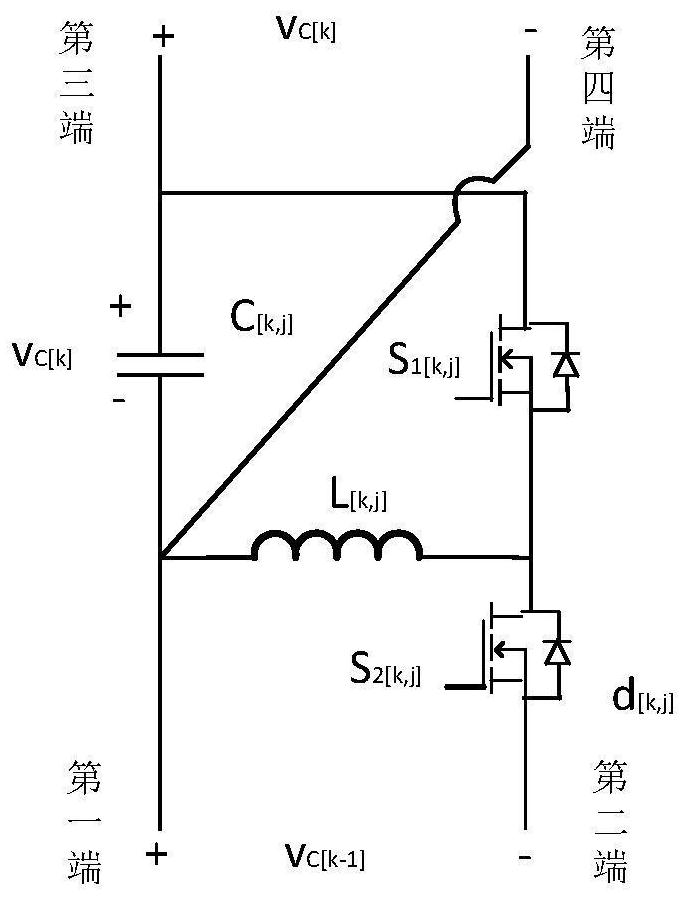

[0029] In one embodiment, the Buck-Boost module in the present invention includes: a capacitor, an inductor, a first switch tube and a second switch tube, the positive terminal of the capacitor is the third terminal of the Buck-Boost module, and the positive terminal of the capacitor Connected to the first end of the first switch tube, the negative end of the capacitor is the fourth end and the first end of the Buck-Boost module, the negative end of the capacitor is connected to one end of the inductor, and the second end of the inductor is connected to the first end of the switch tube The other end of the inductor is connected to the first end of the second switch tube, and the second end of the second switch tube is the second end of the Buck-Boost module.

[0030] Such as image 3 As shown, the Buck-boost circuit contains a capacitor C [k,j] , an inductance L [k,j] and two switching tubes S 1[k,j] ,S 2[k,j] , the capacitance and inductance are respectively connected in ...

Embodiment 3

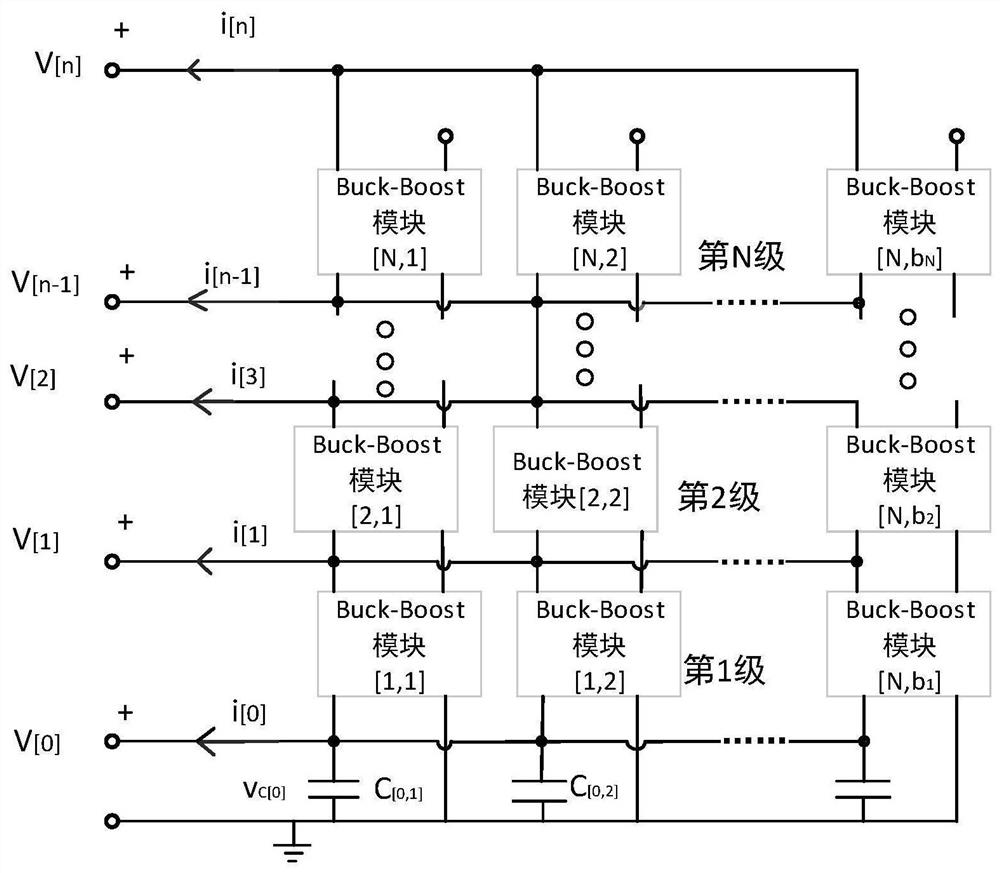

[0033] In one embodiment, the number of stages of the multiple combinational circuits is N, and the number of Buck-Boost modules in each level of multiple combinational circuits is b N , b in the n-1th level combinational circuit i The third terminal of a Buck-Boost module and the bth stage in the nth stage combination circuit i The first ends of the Buck-Boost modules are connected, and the bth in the n-1th level combined circuit i The fourth terminal of a Buck-Boost module and the b-th in the nth-level combined circuit i Connect to the second end of a Buck-Boost module.

[0034] Of course, there may also be a combined circuit with a different number of Buck-Boost modules in each level of combined circuit than in other combined circuits. The number of Buck-Boost modules in this level of combined circuit is related to the current stress distribution relevant.

[0035] In order to facilitate the analysis of the working principle of the converter provided by the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com