A kind of bionic fibrous ring support and preparation method thereof

A fibrous annulus, bionic technology, applied in textiles and papermaking, spinal implants, non-woven fabrics, etc., can solve the problem that the fibrous annulus support has no mechanical gradient change, cannot provide toughness, and cannot simulate the natural fibrous annulus mechanics Problems such as performance transition, to achieve good biocompatibility, excellent biodegradability and compatibility, excellent multi-layer alternating structure and tensile strain performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

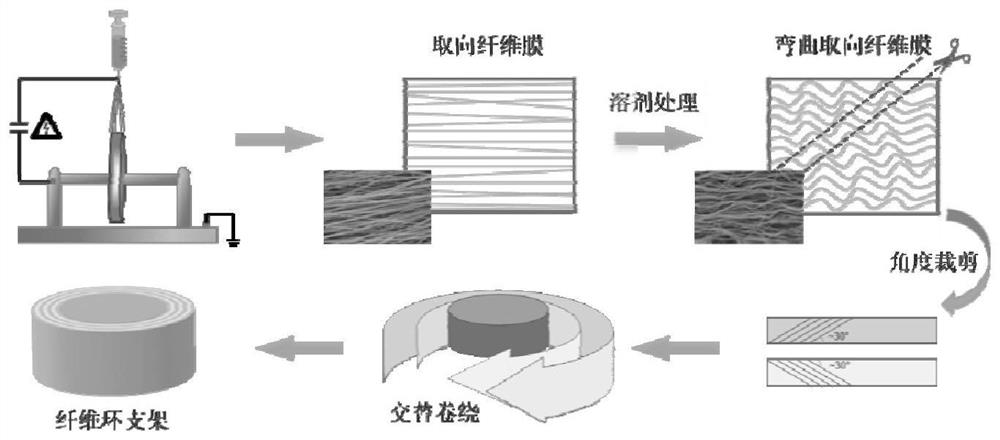

[0041] The preparation method of the bionic annulus fibrosus support in this embodiment comprises the following steps, and the preparation process is as follows: figure 1 Shown:

[0042] (1) 0.8g PLLA was dissolved in 10mL trifluoroethanol to prepare 8% polymer spinning precursor solution, and an electrospinning film was prepared by an electrospinning method; The speed is 3mL / h, the spinning needle is a 9G stainless steel needle, the positive voltage applied to the needle is 12kV, the negative voltage of the corresponding disc receiver is -1kV, and the rotating speed of the disc receiver is 3000r / min , the distance between the needle and the receiver is 10cm; the temperature is 25°C, the relative humidity is 65%, and the time is 1.5h. After the electrospun membrane is prepared, it is dried in a vacuum environment for 12h;

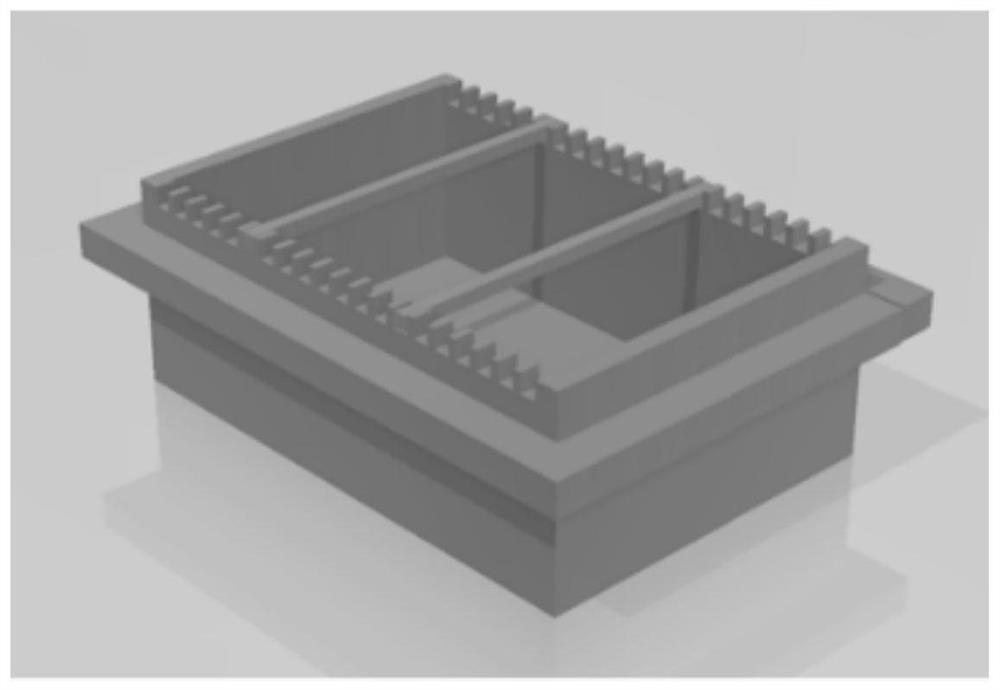

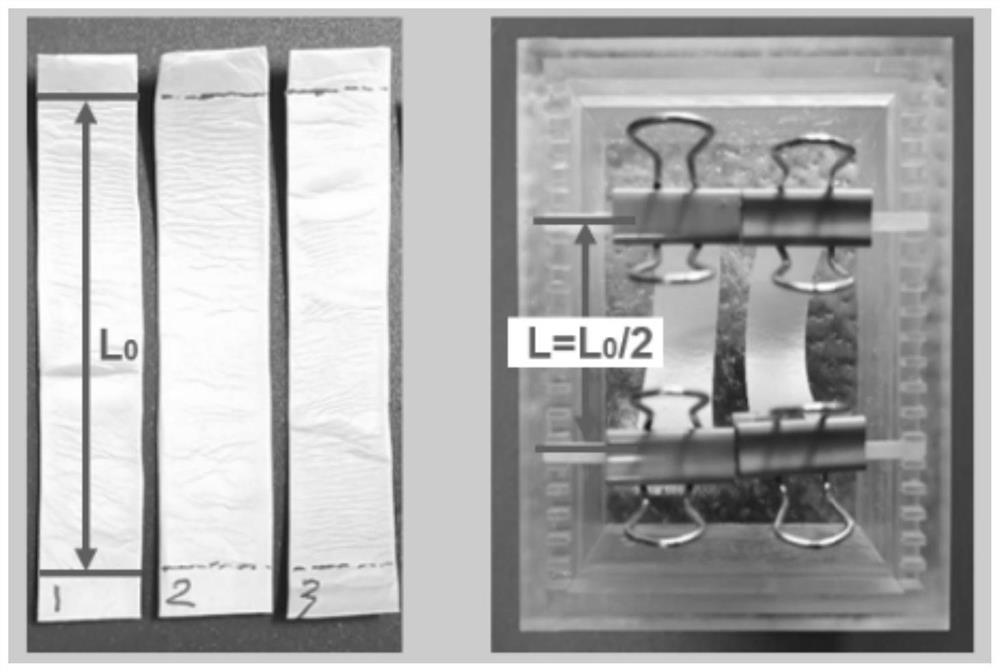

[0043] (2) Cut the electrospun membrane into 1×5cm 2 The long strips are fixed on the fixture with 0.5cm at both ends (the actual induced area of the f...

Embodiment 2

[0048] The preparation method of the bionic fibrous ring support in this embodiment comprises the following steps:

[0049] (1) Dissolve 0.8g PCL in 10mL trifluoroethanol to prepare 8% polymer spinning precursor solution, prepare electrospinning film by electrospinning method; syringe pump when preparing electrospinning film by electrospinning method The speed is 2mL / h, the spinning needle is 9G stainless steel needle, the positive voltage applied to the needle is 15kV, the negative voltage of the corresponding disc receiver is -1kV, and the rotating speed of the disc receiver is 3000r / min , the distance between the needle and the receiver is 8cm; the temperature is 20°C, the relative humidity is 60%, and the time is 1h. After the electrospun membrane is prepared, it is dried in a vacuum environment for 12h;

[0050] (2) Cut the electrospun membrane into 1×5cm 2 The long strips are fixed on the fixture with 0.5cm at both ends (the actual induced area of the fiber membrane i...

Embodiment 3

[0054] The preparation method of the bionic fibrous ring support in this embodiment comprises the following steps:

[0055] (1) 0.8g PLCL was dissolved in 10mL trifluoroethanol to prepare 8% polymer spinning precursor solution, and the electrospinning film was prepared by the electrospinning method; the syringe pump was prepared by the electrospinning method The speed is 2.5mL / h, the spinning needle is 9G stainless steel needle, the positive voltage applied to the needle is 18kV, the negative voltage of the corresponding disk receiver is -1kV, and the rotation speed of the disk receiver is 3000r / min, the distance between the needle and the receiver is 9cm; the temperature is 20°C, the relative humidity is 70%, and the time is 1h. After the electrospun membrane is prepared, it is dried in a vacuum environment for 12h;

[0056] (2) Cut the electrospun membrane into 1×5cm 2 The long strips are fixed on the fixture with 0.5cm at both ends (the actual induced area of the fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com