Water-resistant flame-retardant epoxy resin curing agent and preparation method thereof

An epoxy resin curing and flame-retardant technology, applied in the field of curing agent, can solve the problems of insufficient water resistance and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

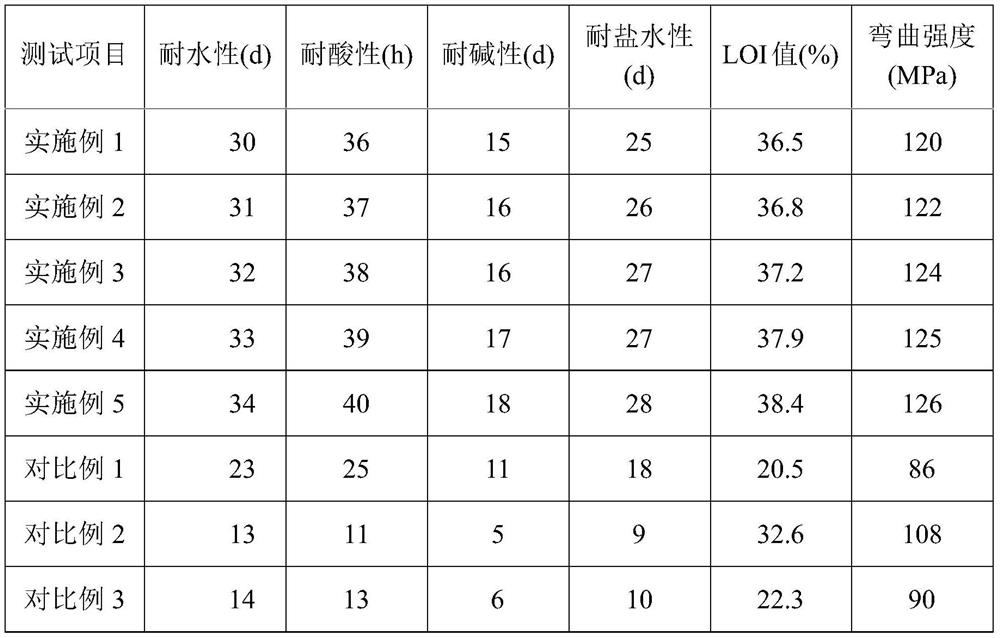

Examples

Embodiment 1

[0025] A water-resistant flame-retardant epoxy resin curing agent is characterized in that it comprises the following raw materials: N-[(10-oxo-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-yl )methyl]-1,3,5-triazine-2,4,6-triamine, epoxy-terminated propylene glycol polyether, aliphatic amine, 1,4-bis(2′,3′-epoxypropyl ) perfluorobutane and alkyl acrylates.

[0026] Furthermore, the preparation method of the epoxy-terminated propylene glycol polyether includes the following steps: adding a solid superacid to the propylene glycol polyether, under nitrogen protection, slowly adding epichlorohydrin, and reacting for 2 hours at 60°C , filter, distill under reduced pressure, add potassium hydroxide, protect with nitrogen, react at 40°C for 6h, filter, neutralize with acetic acid solution, concentrate, and dry to obtain epoxy-terminated propylene glycol polyether.

[0027] Furthermore, the molar ratio of the propylene glycol polyether to epichlorohydrin is 1:2.5.

[0028] Further, ...

Embodiment 2

[0038] A water-resistant flame-retardant epoxy resin curing agent is characterized in that it comprises the following raw materials: N-[(10-oxo-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-yl )methyl]-1,3,5-triazine-2,4,6-triamine, epoxy-terminated propylene glycol polyether, aliphatic amine, 1,4-bis(2′,3′-epoxypropyl ) perfluorobutane and alkyl acrylates.

[0039] Furthermore, the preparation method of the epoxy-terminated propylene glycol polyether includes the following steps: adding a solid superacid to the propylene glycol polyether, under nitrogen protection, slowly adding epichlorohydrin, and reacting at 65°C for 2.5 h, filter, distill under reduced pressure, add potassium hydroxide, protect with nitrogen, react at 45°C for 6.5 h, filter, neutralize with acetic acid solution, concentrate, and dry to obtain epoxy-terminated propylene glycol polyether.

[0040] Furthermore, the molar ratio of the propylene glycol polyether to epichlorohydrin is 1:3.2.

[0041] Furthermo...

Embodiment 3

[0051] A water-resistant flame-retardant epoxy resin curing agent is characterized in that it comprises the following raw materials: N-[(10-oxo-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-yl )methyl]-1,3,5-triazine-2,4,6-triamine, epoxy-terminated propylene glycol polyether, aliphatic amine, 1,4-bis(2′,3′-epoxypropyl ) perfluorobutane and alkyl acrylates.

[0052] Furthermore, the preparation method of the epoxy-terminated propylene glycol polyether includes the following steps: adding a solid superacid to the propylene glycol polyether, under nitrogen protection, slowly adding epichlorohydrin, and reacting for 3 hours at 70°C , filter, distill under reduced pressure, add potassium hydroxide, protect with nitrogen, react for 7 hours at 50°C, filter, neutralize with acetic acid solution, concentrate, and dry to obtain epoxy-terminated propylene glycol polyether.

[0053] Furthermore, the molar ratio of the propylene glycol polyether to epichlorohydrin is 1:3.7.

[0054] Furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com