Device and method for improving mask electrolytic machining precision through arc-shaped spraying cathode movement

A technology of cathode movement and machining accuracy, applied in the direction of electrodes, etc., can solve the problems of low machining efficiency, difficulty in ensuring machining quality and machining accuracy, and no consideration of the uniformity of the size of the micro-pit array structure, so as to ensure the machining quality and reduce the current edge. effect, the effect of improving the localization of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further detailed below with reference to the accompanying drawings and specific embodiments.

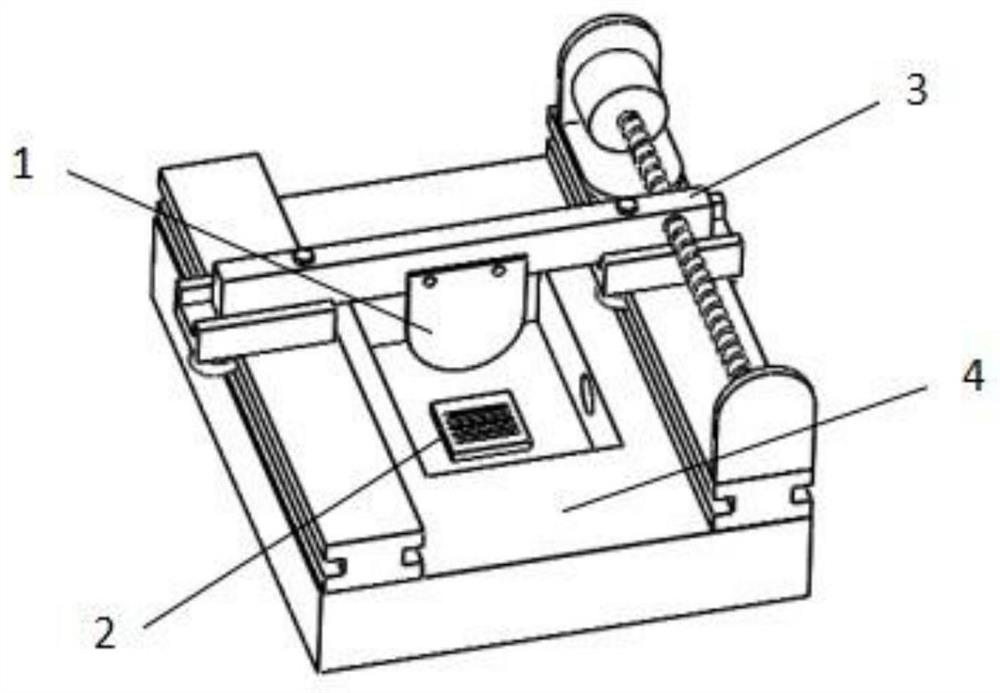

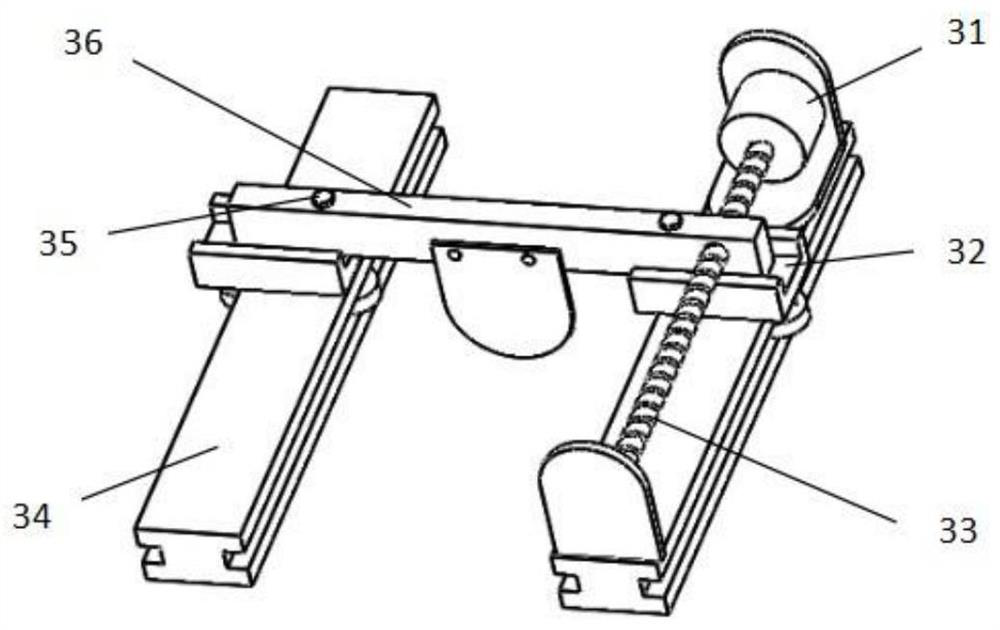

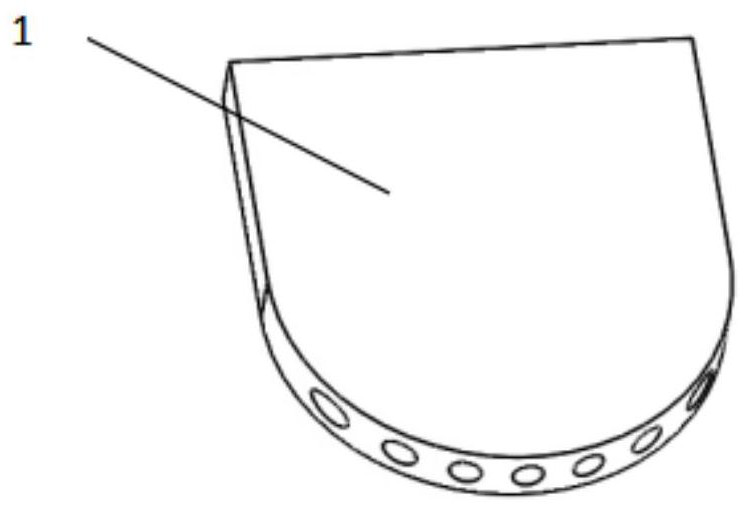

[0039] A curved injection cathode mobile device structure for improving mask electrolysis processing accuracy, such as figure 1 Indicated. This includes: the curved cathode nozzle structure 1, the anode workpiece 2, the moving mechanism 3, the electrolytic cell 4, the anode workpiece 2 is placed at the bottom of the electrolytic cell 4, and the moving mechanism 3 is fixed to the electrolytic cell 4, and the curved cathode nozzle structure 1 is fixed The moving mechanism 3 is above. Mobile mechanism 3 structurefigure 2 As shown, the motor 31 drives the transmission screw 33 to rotate, and the drive screw 33 is driven to fit the moving slider 32 assembled thereto along the guide rail 34 to perform a phase transfer movement. The support beam 36 is connected to the moving slider 32 by tightening the screw 35. Such as image 3 The schematic shown in the curved c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com