A kind of durable flame-retardant low-smoke polyester fabric and preparation method thereof

A polyester fabric, durable flame-retardant technology, applied in the field of durable flame-retardant low-smoke polyester fabric and its preparation, can solve the problems of high fire risk, large smoke release, poor washing resistance, etc., to reduce the experimental process, molecular The effect of increased exercise and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

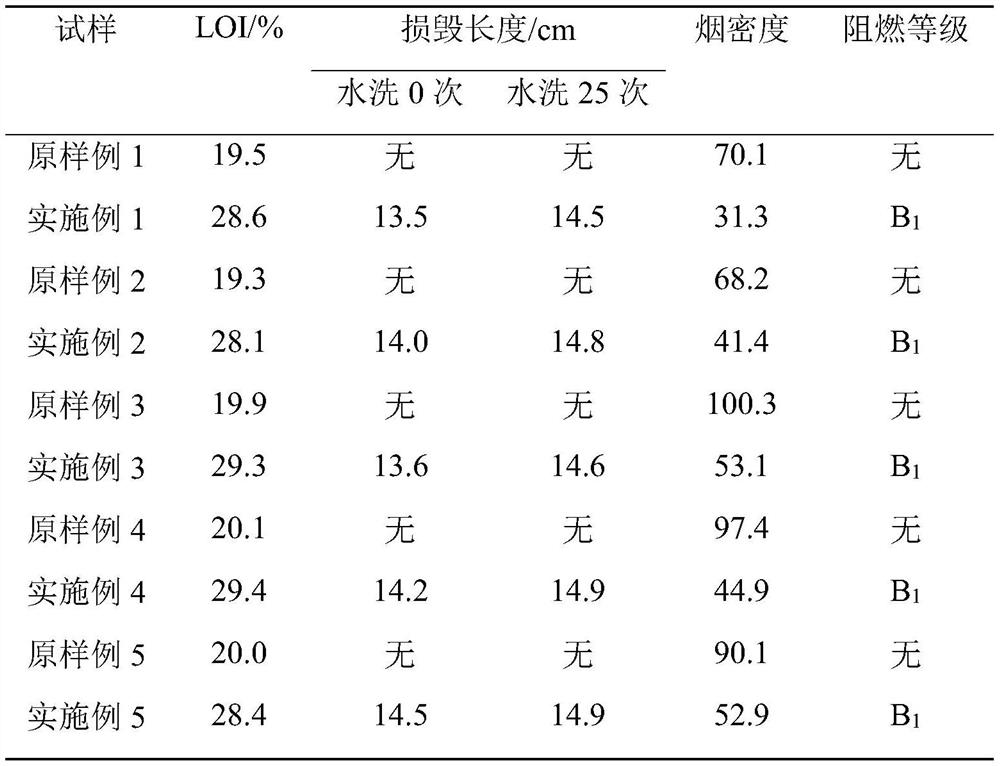

Embodiment 1

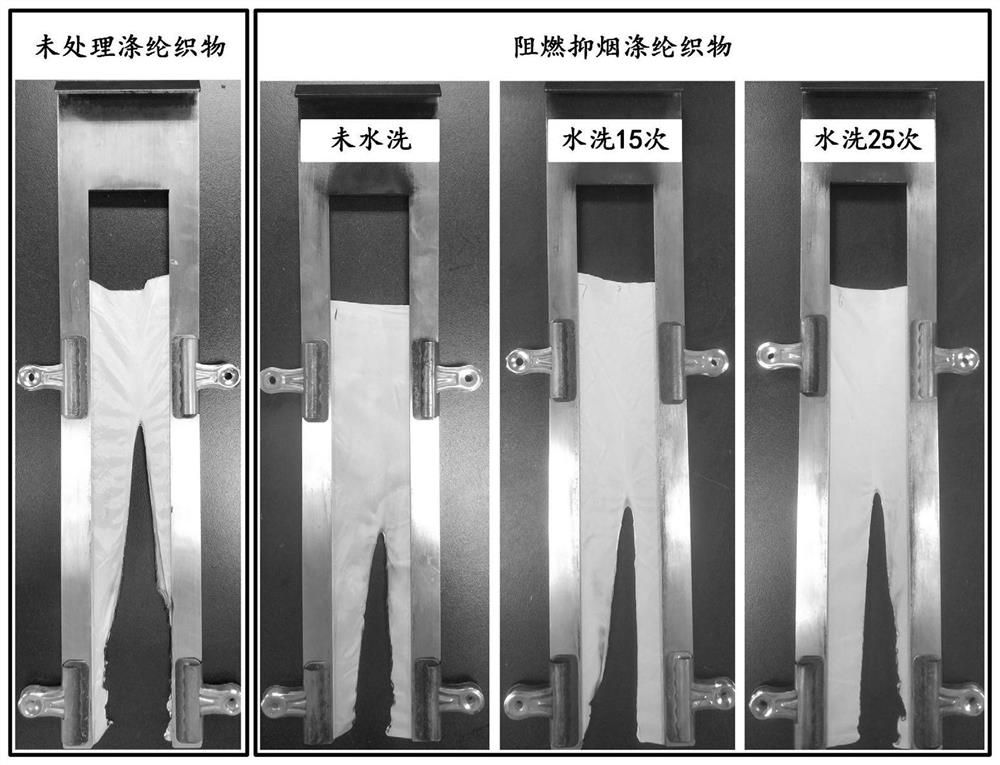

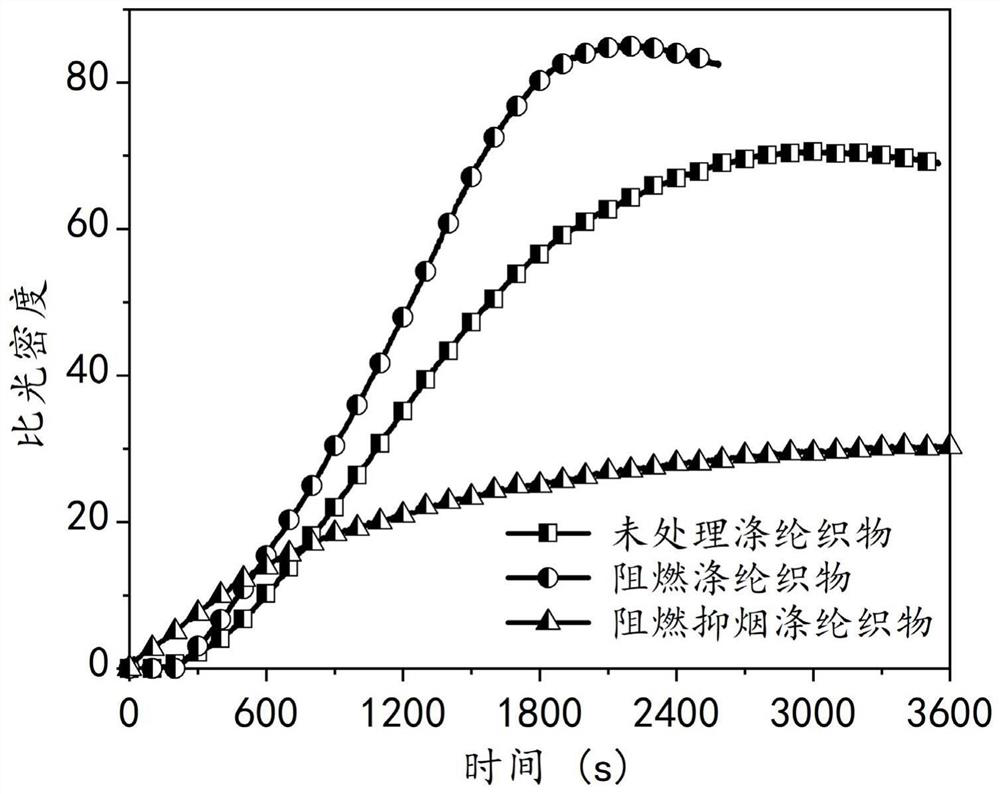

[0029] A durable flame-retardant low-smoke recycled polyester fabric and a preparation method thereof, the specific steps are as follows:

[0030] (1) Preparation of nano-magnesium hydroxide: Add 0.1g Tween 80 into 200mL (1.5mol / L) magnesium chloride solution, completely dissolve and evenly disperse in the solution, place it in the dropping funnel A; take 200mL ( 1.5mol / L) sodium hydroxide solution was placed in the dropping funnel B; the above-mentioned magnesium chloride solution and sodium hydroxide solution were added dropwise to 50mL (0.75mol / L) sodium chloride lining at a rate of 3.3mL / min. In the bottom solution, while maintaining the speed of 1200r / min, the temperature of the water bath is 60°C. After the reaction is complete, it is centrifuged and washed until no chlorine ions are detected, and then vacuum-dried at 60°C for 6 hours to obtain white nano-magnesium hydroxide.

[0031] (2) configure the finishing solution: the nano-magnesium hydroxide and FRC-1 obtained i...

Embodiment 2

[0036] A durable flame-retardant low-smoke primary polyester fabric and a preparation method thereof, the specific steps are as follows:

[0037] (1) Preparation of nano-magnesium hydroxide: Add 0.1g oleic acid into 200mL (1.5mol / L) magnesium chloride solution, completely dissolve and evenly disperse in the solution, then place it in the dropping funnel A; take 200mL (4.5 mol / L) sodium hydroxide solution is placed in dropping funnel B; With the dropping speed of 3.3mL / min, above-mentioned magnesium chloride solution and sodium hydroxide solution are added dropwise to 50mL (0.75mol / L) sodium chloride substrate simultaneously In the solution, while maintaining the speed of 1200r / min, the temperature of the water bath is 70°C. After the reaction is complete, it is centrifuged and washed until no chlorine ions are detected, and then vacuum-dried at 60°C for 6 hours to obtain white nano-magnesium hydroxide.

[0038] (2) Configure the finishing solution: the nano-magnesium hydroxide...

Embodiment 3

[0041] A durable flame-retardant low-smoke primary polyester fabric and a preparation method thereof, the specific steps are as follows:

[0042] (1) Preparation of nano-magnesium hydroxide: 0.1g sulfo-salicylic acid is added in 200mL (1.5mol / L) magnesium chloride solution, after completely dissolving and uniformly dispersed in the solution, it is placed in the dropping funnel A; 200mL (3mol / L) sodium hydroxide solution is placed in dropping funnel B; With the dropping rate of 3.3mL / min, above-mentioned magnesium chloride solution and sodium hydroxide solution are added dropwise to 50mL (0.75mol / L) sodium chloride solution simultaneously In the substrate solution, while maintaining the rotational speed of 1200r / min, the temperature of the water bath is 80°C. After the reaction is complete, it is centrifuged and washed until no chlorine ions are detected, and then vacuum-dried at 60°C for 6 hours to obtain white nano-magnesium hydroxide.

[0043] (2) Configure the finishing sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com