A method for preparing nitrogen-doped graphitized carbon

A technology of graphitized carbon and nitrogen doping, which is applied in the manufacture of hybrid/electric double layer capacitors, structural parts, electrical components, etc., and can solve problems such as complex and cumbersome processes, poor graphite rate performance, and low graphitization degree of graphitized carbon , to achieve the effect of shortening the experimental process, improving the degree of graphitization, and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of nitrogen-doped graphitized carbon, comprising the following steps:

[0037] (1) Mix ferric ammonium citrate and urea in a ratio of 1:3, add 100ml of deionized water to dissolve, transfer to the reaction kettle and heat at 180°C for 6 hours, and evaporate the solvent in the product of the hydrothermal reaction to obtain the reaction Precursor;

[0038] (2) Sinter the precursor at 1300°C to obtain a carbon material containing metal element and metal carbide, wash with 0.5 mol / L hydrochloric acid to remove the metal element and metal carbide, wash with water until neutral vacuum drying to obtain nitrogen doping graphitized carbon materials.

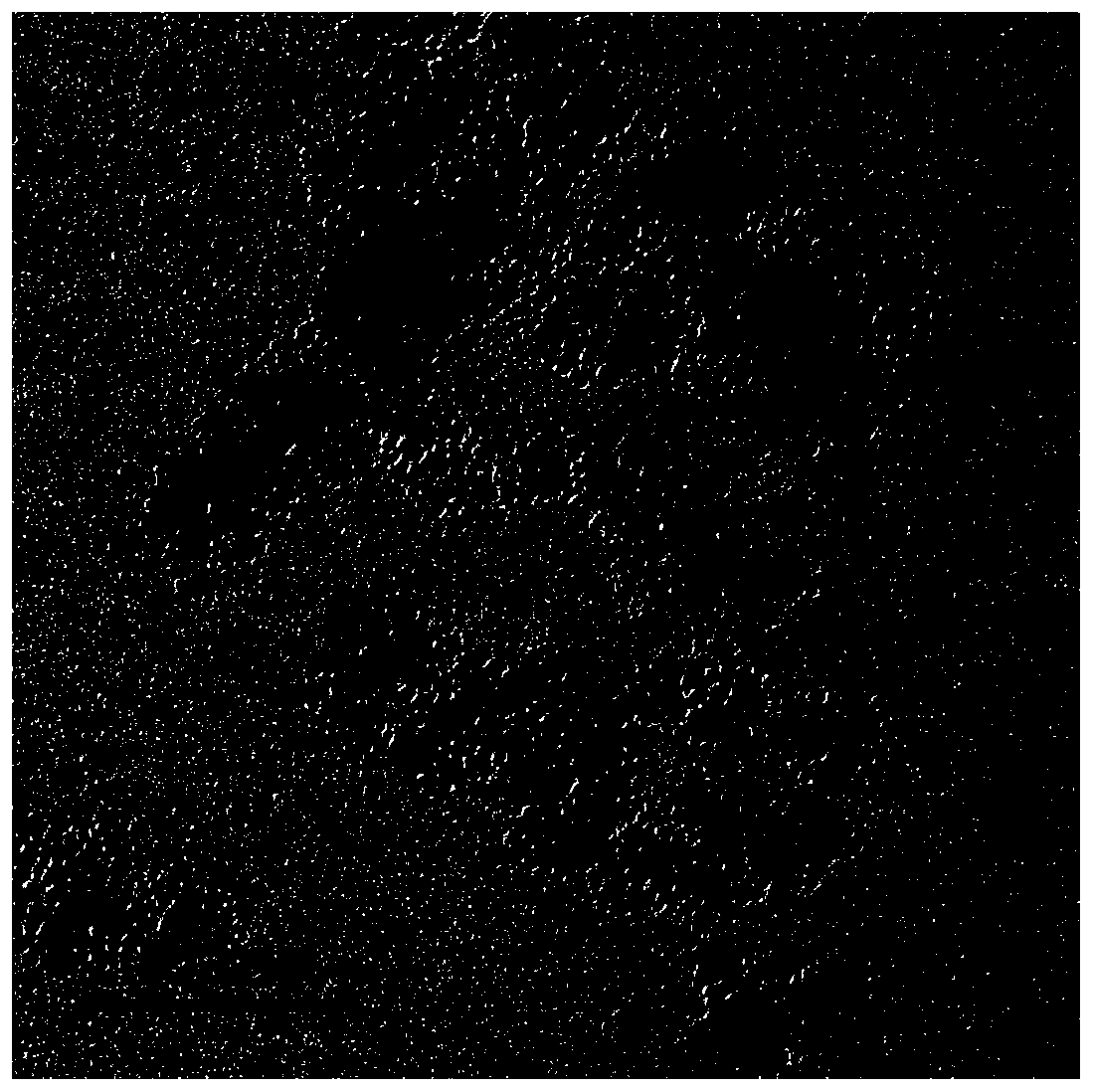

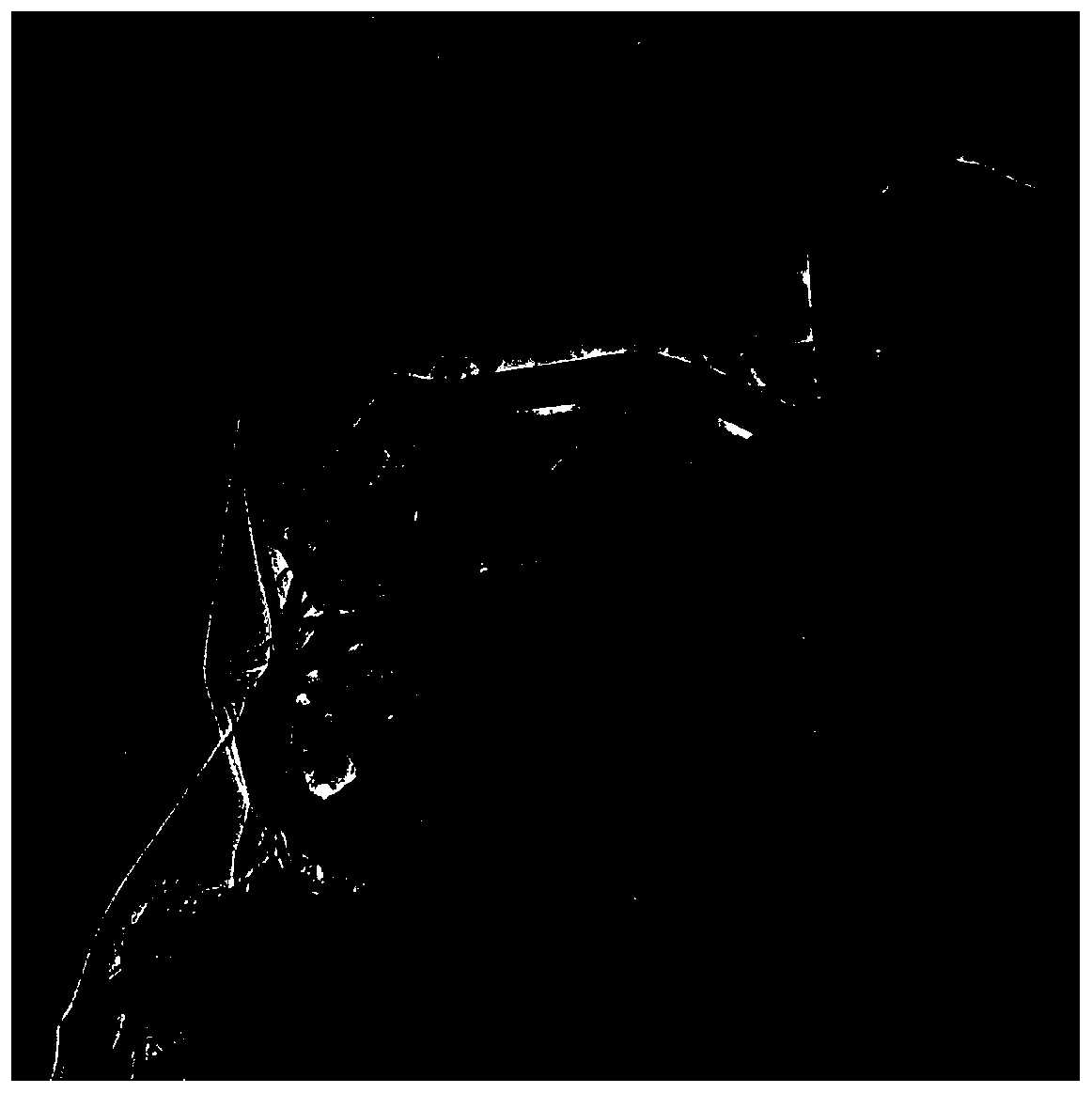

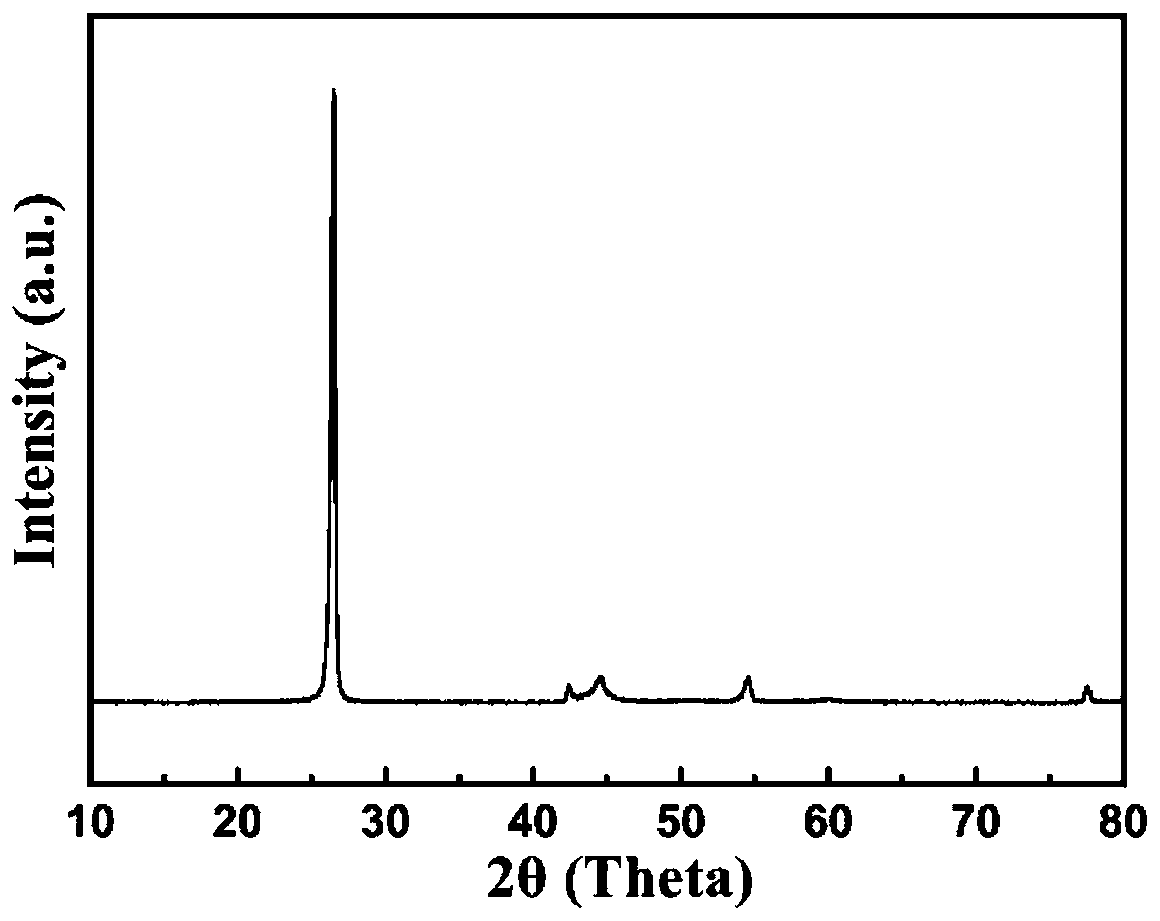

[0039] pass image 3 and Figure 4 The comparison shows that the (002) peak of the graphitized carbon material graphite prepared by the present invention is sharp and strong, and has a higher graphitization tendency. According to the specific surface area test and pore size distribution test, the specific s...

Embodiment 2

[0041] A method for preparing a silicon-carbon composite negative electrode material, comprising the following steps:

[0042] (1) Mix ferric citrate and urea in a ratio of 1:3, add 100ml of deionized water to dissolve, transfer to the reaction kettle and heat at 180°C for 6 hours, and evaporate the solvent in the product of the hydrothermal reaction to obtain the reaction precursor body;

[0043] (2) Sinter the precursor at 1300°C to obtain a carbon material containing metal element and metal carbide, wash with 0.5 mol / L hydrochloric acid to remove the metal element and metal carbide, wash with water until neutral vacuum drying to obtain nitrogen doping graphitized carbon materials.

[0044] The obtained materials were assembled into button batteries, and the charge and discharge performance tests were carried out. The results show that the graphitized carbon prepared by this method can achieve 340.2 mAh / g as an anode material for lithium-ion batteries, and has excellent cy...

Embodiment 3

[0046] A method for preparing a silicon-carbon composite negative electrode material, comprising the following steps:

[0047](1) Mix nickel citrate and urea in a ratio of 1:3, add 100ml of deionized water to dissolve, transfer to the reaction kettle and heat at 180°C for 6 hours, and evaporate the solvent in the product of the hydrothermal reaction to obtain the reaction precursor body;

[0048] (2) Sinter the precursor at 1300°C to obtain a carbon material containing metal element and metal carbide, wash with 0.5 mol / L hydrochloric acid to remove the metal element and metal carbide, wash with water until neutral vacuum drying to obtain nitrogen doping graphitized carbon materials.

[0049] The obtained materials were assembled into button batteries, and the charge and discharge performance tests were carried out. The results show that the graphitized carbon prepared by this method can achieve 334.2 mAh / g as an anode material for lithium-ion batteries, and has excellent cyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com