Preparation method of sunscreen microspheres

A technology of microspheres and solutions, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of large size, low sun protection performance, low performance, etc., to improve SPF value and PA value , improve sun protection comfort, and strong skin-friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

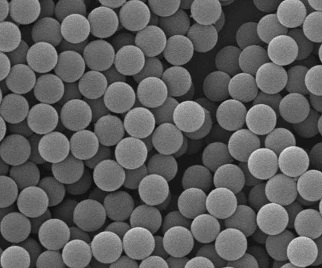

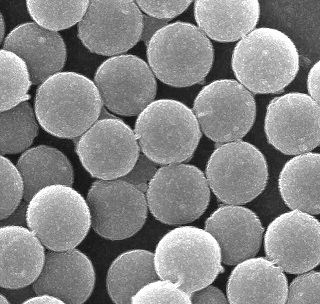

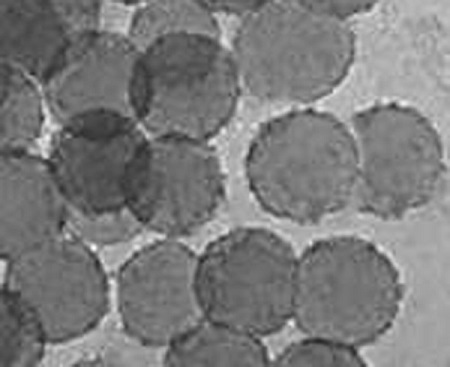

Image

Examples

Embodiment 1

[0041] A preparation method of sunscreen liquid microspheres, comprising the steps of:

[0042] 1) Add 72mg of initiator azobisisobutyronitrile, 2.5g of dispersant polyvinylpyrrolidone, and 0.79ml of crosslinking agent ethylene glycol dimethacrylate into a solvent of 95vol.% acetonitrile / 5vol.% toluene, fully Disperse to obtain a solution.

[0043] 2) Add 3g of methyl methacrylate and 1.5g of acrylamide to the solution obtained in step 1), slowly pass through N2 protection for 30min, and then rise to the reaction temperature of 85°C. After 4 hours of continuous reaction, the experiment is over, and the product is poured out. Vacuum filtration, tetrahydrofuran cleaning, 80 o C was washed with deionized water to obtain a white solid.

[0044] 3) Ultrasonic disperse 3g of the above white solid in 150ml of absolute ethanol, slowly add 75ml of 0.025M zinc acetate ethanol solution, let stand for 10min; then add 100ml of 0.05M zinc acetate ethanol solution, and continue stirring. ...

Embodiment 2

[0049] A preparation method of sunscreen liquid microspheres, comprising the steps of:

[0050] 1) Add 72mg of initiator azobisisobutyronitrile, 2.5g of dispersant polyvinylpyrrolidone, and 0.79ml of crosslinking agent ethylene glycol dimethacrylate into a solvent of 95vol.% acetonitrile / 5vol.% toluene, fully Disperse to obtain a solution.

[0051] 2) Add 3g of methyl methacrylate and 1.5g of acrylamide to the solution obtained in step 1), slowly pass through N2 protection for 30min, and then rise to the reaction temperature of 85°C. After 4 hours of continuous reaction, the experiment is over, and the product is poured out. Vacuum filtration, tetrahydrofuran cleaning, 80 o C was washed with deionized water to obtain a white solid.

[0052] 3) Ultrasonic disperse the above 4g of white solid in 150ml of absolute ethanol, slowly add 82.5ml of 0.03M zinc acetate ethanol solution, let it stand for 12.5min; then add 105ml of 0.06M zinc acetate ethanol solution, and continue stirr...

Embodiment 3

[0057] A preparation method of sunscreen liquid microspheres, comprising the steps of:

[0058] 1) Add 72mg of initiator azobisisobutyronitrile, 2.5g of dispersant polyvinylpyrrolidone, and 0.79ml of crosslinking agent ethylene glycol dimethacrylate into a solvent of 95vol.% acetonitrile / 5vol.% toluene, fully Disperse to obtain a solution.

[0059] 2) Add 3g of methyl methacrylate and 1.5g of acrylamide to the solution obtained in step 1), slowly pass through N2 protection for 30min, and then rise to the reaction temperature of 85°C. After 4 hours of continuous reaction, the experiment is over, and the product is poured out. Vacuum filtration, tetrahydrofuran cleaning, 80 o C was washed with deionized water to obtain a white solid.

[0060] 3) Ultrasonic disperse 5g of the above white solid in 150ml of absolute ethanol, slowly add 90ml of 0.05M zinc acetate ethanol solution, and let it stand for 15min; then add 110ml of 0.075M zinc acetate ethanol solution, and continue stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com