Degradable polyester and preparation method and product thereof

A technology for degrading polyester and esterified products, applied in the field of materials, can solve problems such as threats to biological health and survival, human health, slow degradation rate, etc., and achieve the effects of easy implementation, solution to marine plastic pollution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a kind of preparation method of described degradable polyester, comprising:

[0042] S1, mixing diglycolic acid, dibasic acid or its esterified product, aliphatic dihydric alcohol and an esterification catalyst, and performing an esterification reaction to obtain an esterification product;

[0043] S2, performing a polycondensation reaction on the esterified product to obtain a degradable polyester.

[0044] The reaction equation of the preparation method is as follows:

[0045]

[0046] Wherein, in order to ensure the carrying out of the esterification reaction, in step S1, the molar ratio of the sum of the molar weights of the diglycolic acid and the dibasic acid or its esterified product to the aliphatic glycol is 1:1.6 -1:1.1, the molar ratio of the diglycolic acid to the dibasic acid or its esterified product is 0.1:1-10:1, more preferably 0.1:1-2:1, more preferably 0.1:1 -1.5:1, so that the obtained degradable polyester has b...

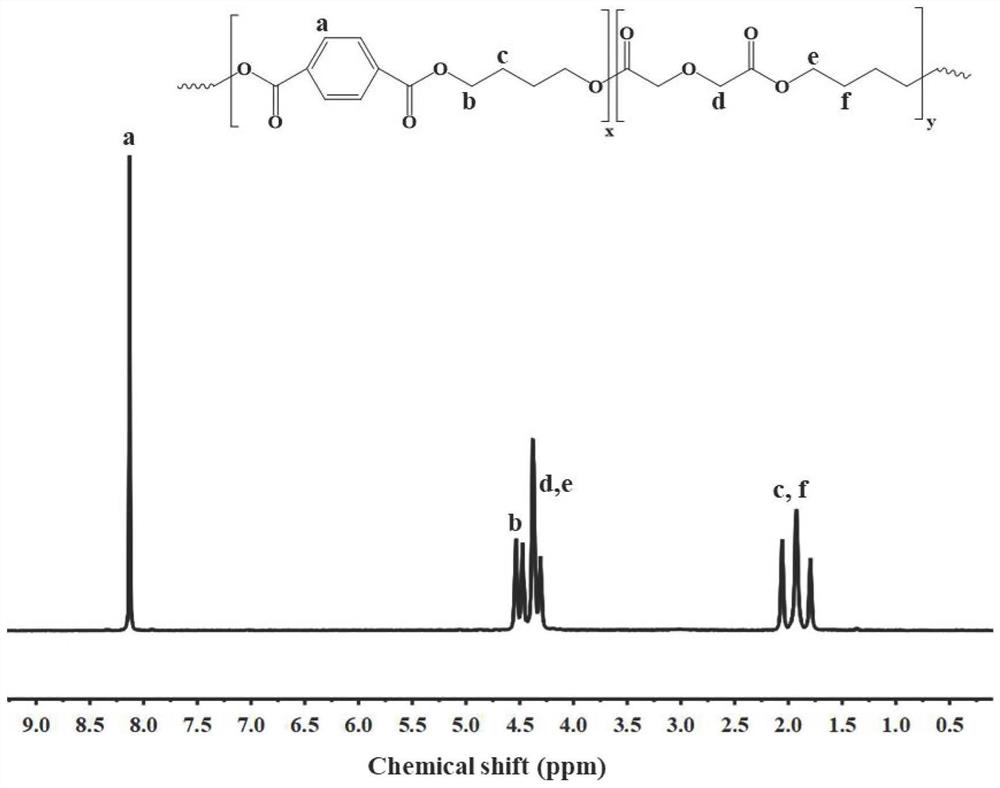

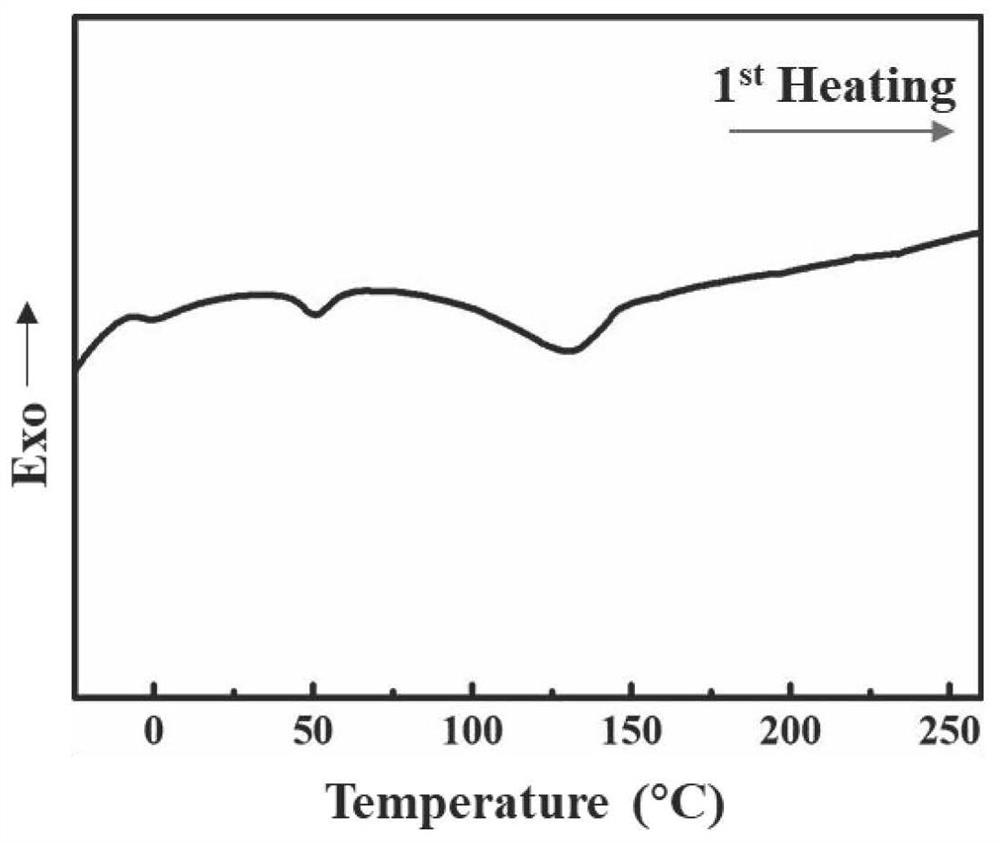

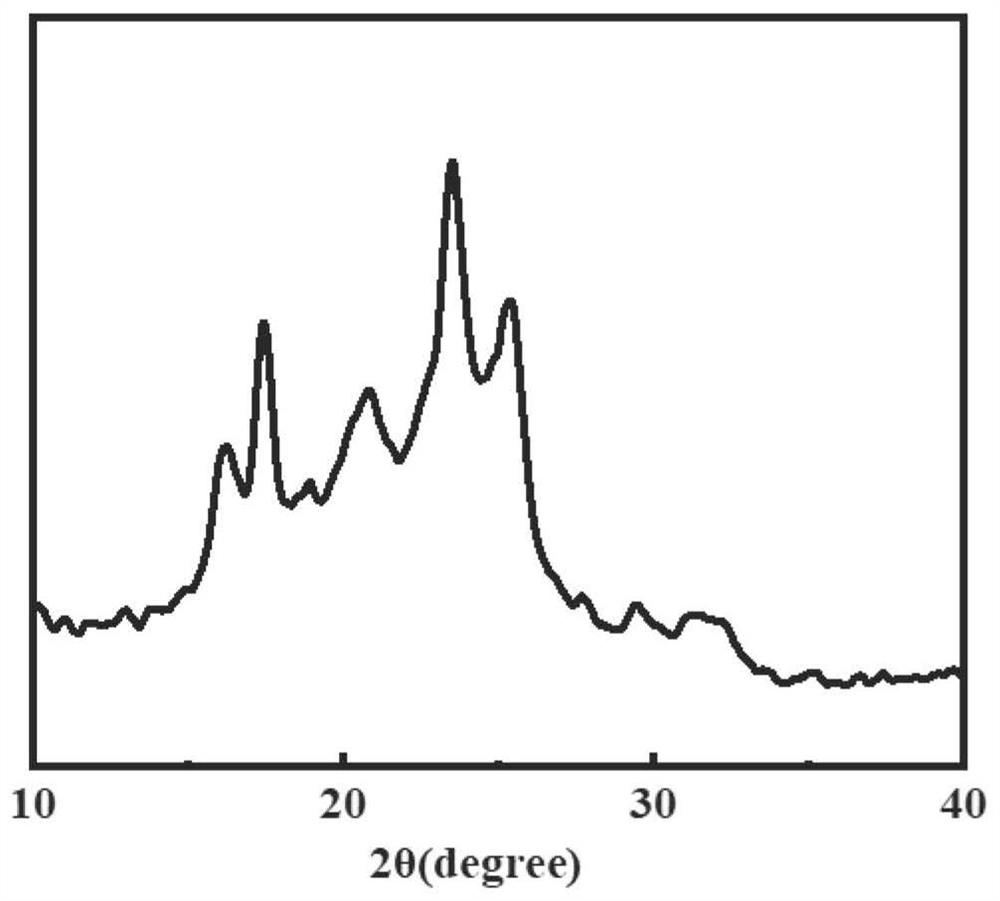

Embodiment 1

[0065] Take respectively 29.1g (0.15mol) of dimethyl terephthalate, 20.1g (0.15mol) of diglycolic acid, 40.6g (0.45mol) of 1,4-butanediol and 0.2% of the total mass of raw materials Antimony glycol, placed in a reactor, and mechanically stirred and blended at 170°C-190°C under the protection of high-purity nitrogen, reacted for 5 hours to obtain an esterified product.

[0066] Add 0.2% antimony trioxide, 0.4% triphenyl phosphate and 0.6% antioxidant 1076 to the above-mentioned esterification product, mechanically stir and blend, and carry out polycondensation reaction. The reaction temperature of polycondensation reaction is 200°C-240°C, the vacuum degree of the reaction system gradually drops below 200Pa, and the reaction ends after 7 hours. Under the protection of high-purity nitrogen, the temperature of the reactor is gradually lowered to room temperature, and a colorless or light yellow solid product is obtained, namely For degradable polyester, the structural formula is a...

Embodiment 2

[0076] Take 34.2g (0.225mol) of 2,5-furandicarboxylic acid, 20.1g (0.15mol) of diglycolic acid, 27.04g (0.3mol) of 1,4-butanediol, 9.31g (0.15mol) of ethylene glycol Diol and dibutyltin oxide with a total mass of 0.2% were placed in a reactor, and mechanically stirred and blended at 180°C-190°C under the protection of high-purity nitrogen, and the esterification product was obtained after 6 hours of reaction.

[0077] Add 0.2% of tetrabutyl titanate, 0.1% of antimony trioxide, 0.5% of diphenyl phosphate and 0.5% of antioxidant 168 into the above esterification product, mechanically stir and blend, and carry out Polycondensation reaction, the reaction temperature of polycondensation reaction is 210°C-240°C, the vacuum degree of the reaction system gradually drops below 200Pa, and the reaction ends after 8 hours. Under the protection of high-purity nitrogen, the temperature of the reactor is gradually lowered to room temperature, and no Color or light yellow solid product is deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com