Method for safely and efficiently recycling lithium from waste battery

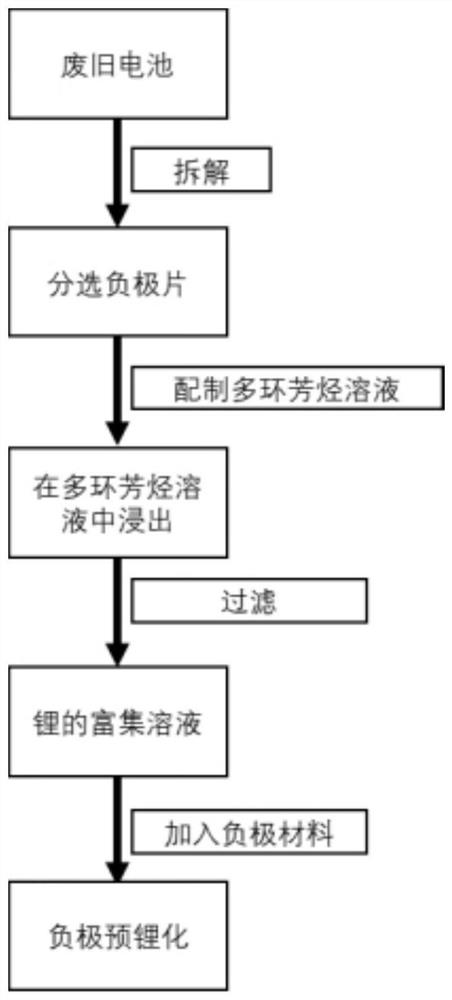

A waste battery, safe technology, applied in the direction of battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of high risk of negative electrode materials, hidden safety hazards, complicated operation, etc., to achieve optimized electrode structure rearrangement, safety High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

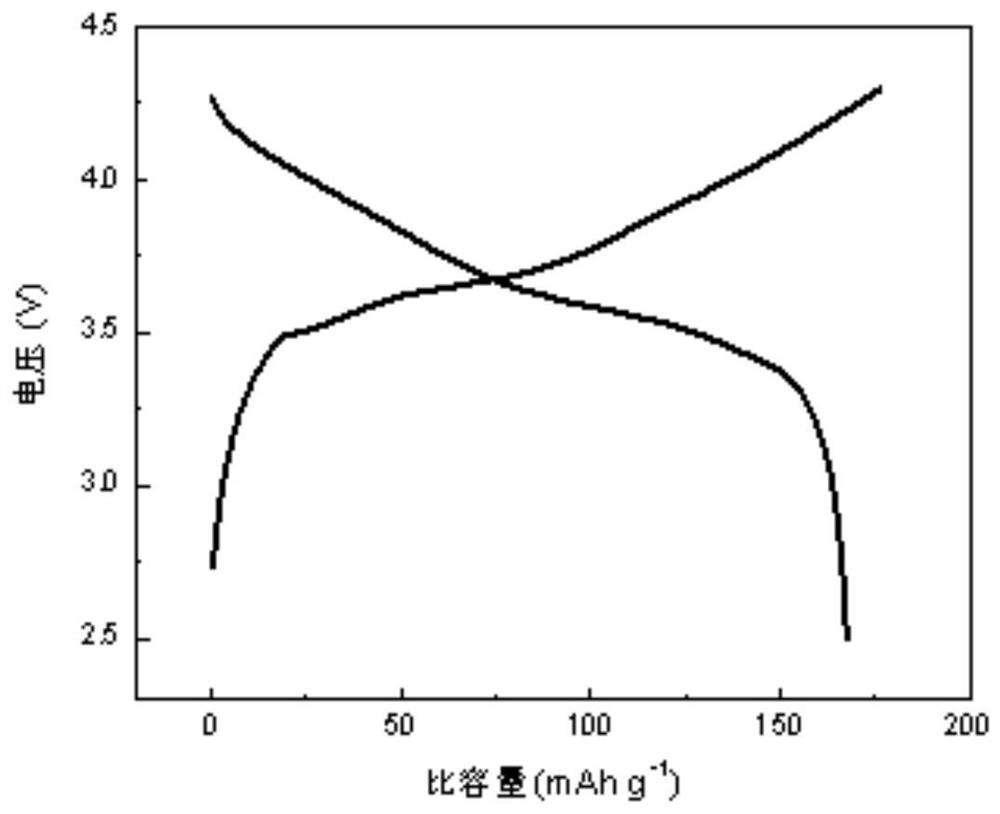

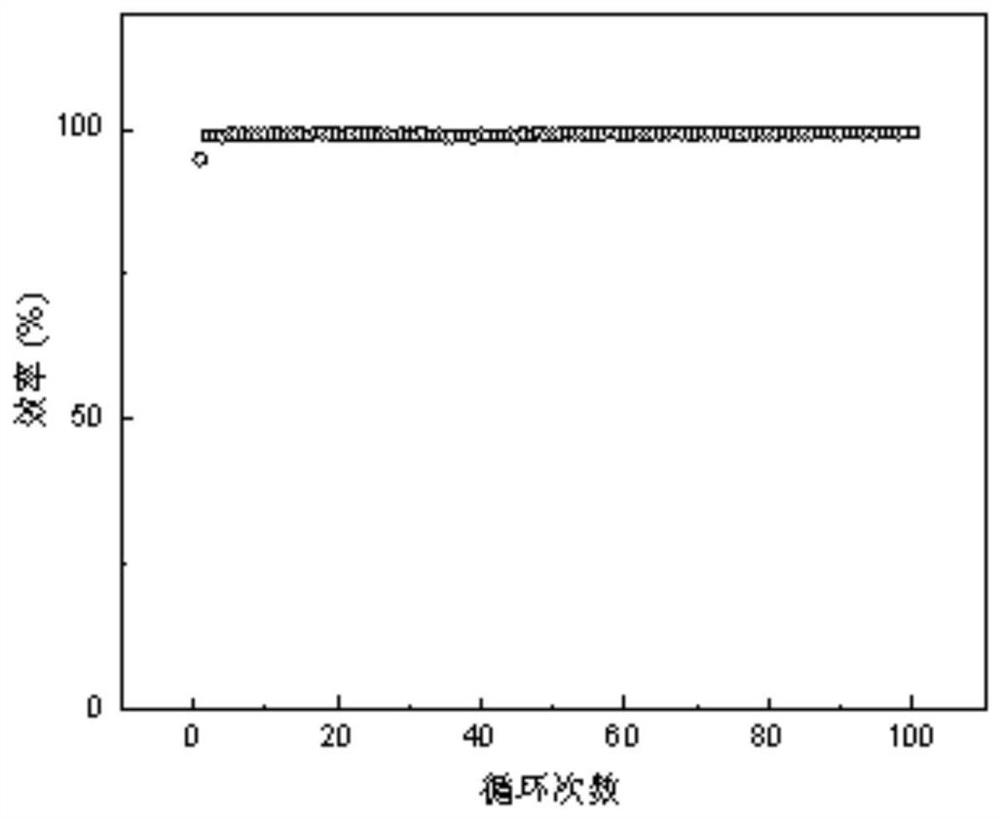

[0054] (1) Use the constant current and constant voltage three-stage charging method to charge the waste nickel-cobalt lithium manganese oxide battery. When the charging voltage reaches 3.5V, change to constant current charging until the voltage reaches 4.3V, and then change to constant charging again. Voltage charging, until the charging current density drops to 10% of the constant current charging current density, the voltage remains stable, and the charging is stopped;

[0055] (2) disassemble the waste lithium-ion battery in a dry room with a relative humidity of 5%, take out the disassembled negative electrode, and cut it to a suitable size;

[0056] (3) Plasma treatment of the negative plate: using Ar / N 2 As a gas source, its power is 80W, the processing time is 5min, the flow rate of working gas is 30sccm, and then naturally cooled to room temperature;

[0057] (4) Prepare the leaching solution, add 15.4 g of biphenyl and 100 ml of diethylene glycol dimethyl ether solv...

Embodiment 2

[0063] (1) Use the constant current and constant voltage three-stage charging method to charge the waste lithium iron phosphate battery. When the charging voltage reaches 3.5V, change to constant current charging until the voltage reaches 4.2V, and then change to constant voltage charging again. , until the charging current density drops to 10% of the constant current charging current density, the voltage remains stable, and the charging is stopped;

[0064] (2) disassemble the waste lithium-ion battery in a dry room with a relative humidity of 5%, take out the disassembled negative electrode, and cut it to a suitable size;

[0065] (3) Plasma treatment of the appropriate negative plate: using Ar / N 2 As a gas source, its power is 80W, the processing time is 5min, the flow rate of working gas is 50sccm, and then naturally cooled to room temperature;

[0066] (4) Configure the leaching solution, add 12.8g of naphthalene and 100ml of diethylene glycol dimethyl ether solvent into...

Embodiment 3

[0071] (1) Use the constant current and constant voltage three-stage charging method to charge the waste lithium iron phosphate battery. When the charging voltage reaches 3.5V, change to constant current charging until the voltage reaches 4.2V, and then change to constant voltage charging again. , until the charging current density drops to 10% of the constant current charging current density, the voltage remains stable, and the charging is stopped;

[0072] (2) disassemble the waste lithium-ion battery in a dry room with a relative humidity of 5%, take out the disassembled negative electrode, and cut it to a suitable size;

[0073] (3) Plasma treatment of the appropriate negative plate: using Ar / N 2 As a gas source, its power is 100W, the processing time is 5min, the influx of working gas is 50sccm, and then naturally cooled to room temperature;

[0074] (4) Configure the leaching solution, add 17.8g phenanthrene and 100ml diethylene glycol dimethyl ether solvent into the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com