Aluminum alloy material for high-strength and high-toughness glasses frame and preparation method of aluminum alloy material

An aluminum alloy material, high toughness technology, used in glasses/goggles, optics, instruments, etc., can solve the problems of poor resistance to deformation, limited use of aluminum alloys, low yield strength, etc., to achieve low internal stress and low segregation tendency , the effect of fine grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

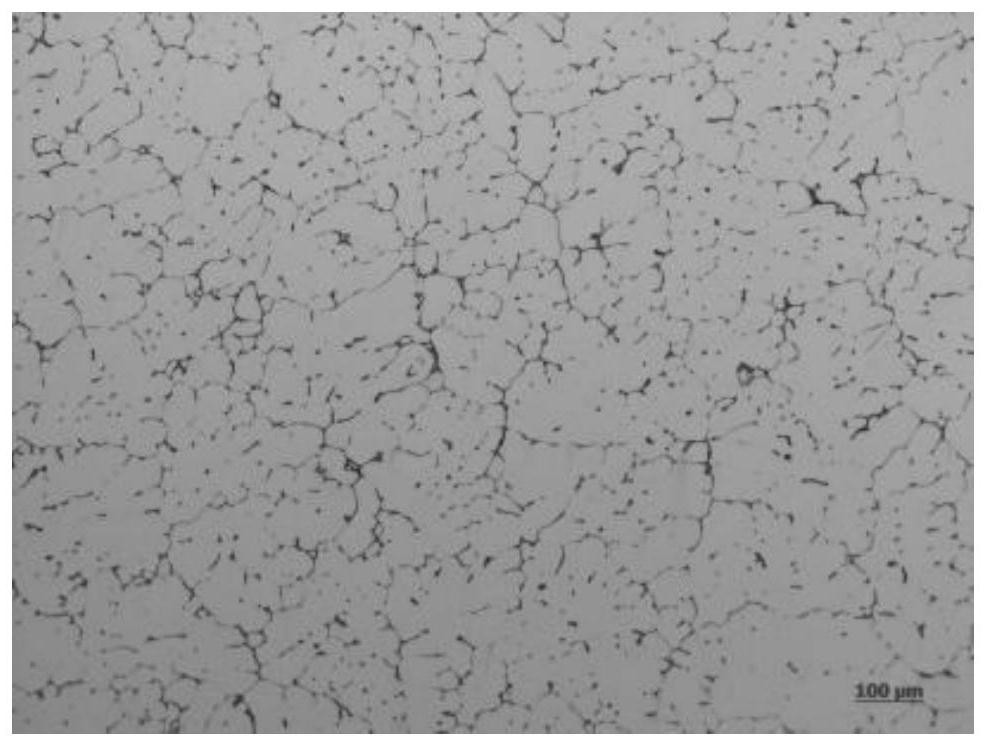

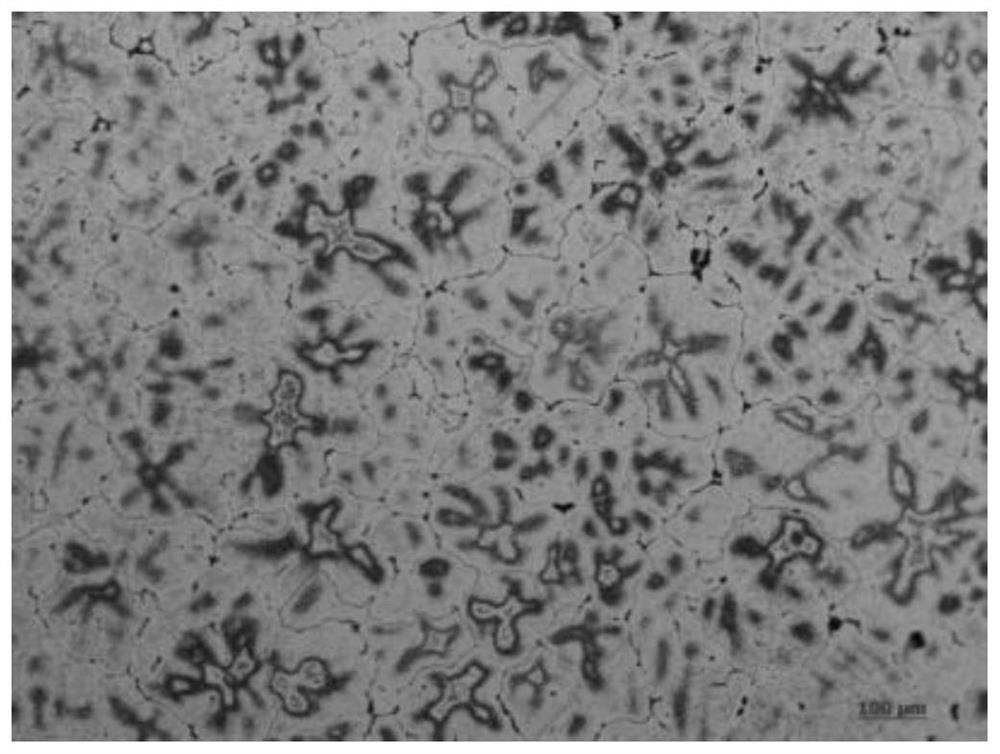

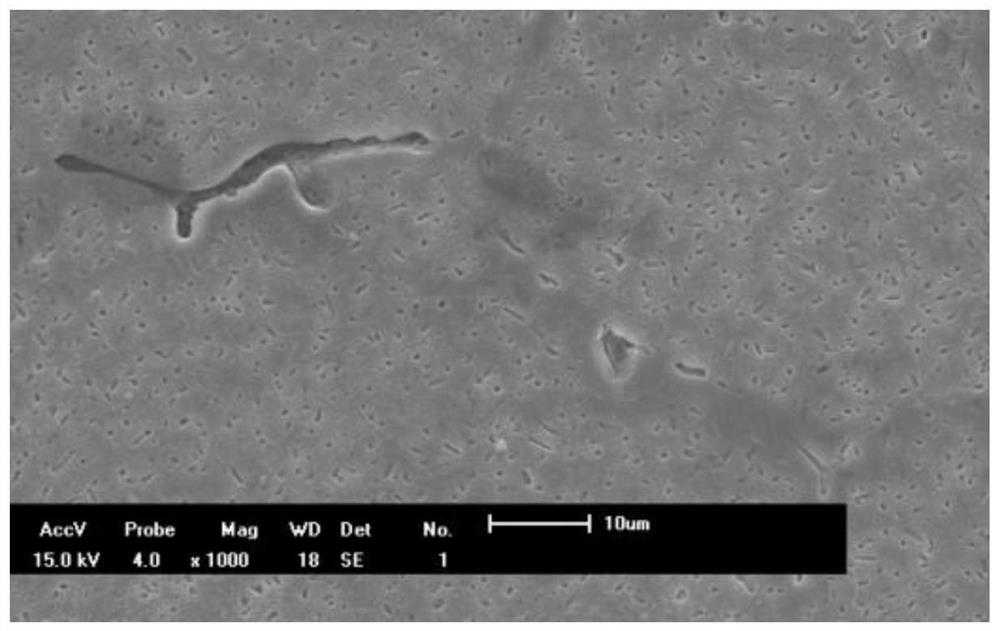

[0044] The invention provides a high-strength and high-toughness aluminum alloy material for spectacle frames, the chemical composition of which includes: 0.25-0.30% Si content, 0.22-0.27% Fe content, and 0.22-0.27% Cu content. 1.5-2.1%, the content of Mn is 0.25-0.40%, the content of Mg is 2.2-3.2%, the content of Cr is 0.10-0.20%, the content of Zn is 4.7-5.6%, the content of Zr is 0.07-0.15%, The content of RE is 0.07-0.15%, the content of Ti is 0.27-0.35%, and the balance is Al.

[0045]Examples of high-strength and high-toughness aluminum alloys for spectacle frames include the main alloy elements Zn, Mg, and Cu, which belong to the 7-series alloy superhard aluminum alloy, which can be strengthened by heat treatment, and have good wear resistance, weldability and high yield Strength, is a high-quality base metal for eyeglass frames. There are many strengthening phases such as MgZn2, S phase (Al2CuMg), T phase (AlCuMgZn) and so on in the alloy.

[0046] The examples cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com