Graphene-assisted vanadium oxide thermo-optical modulator and preparation process thereof

A vanadium oxide thermo-optic and graphene technology, applied in the field of light modulation, can solve the problems of poor thermal stability of microring light modulators, large insertion loss of plasma light modulators, low extinction of electroabsorption light modulators, etc. The effect of wide wavelength range, low insertion loss and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

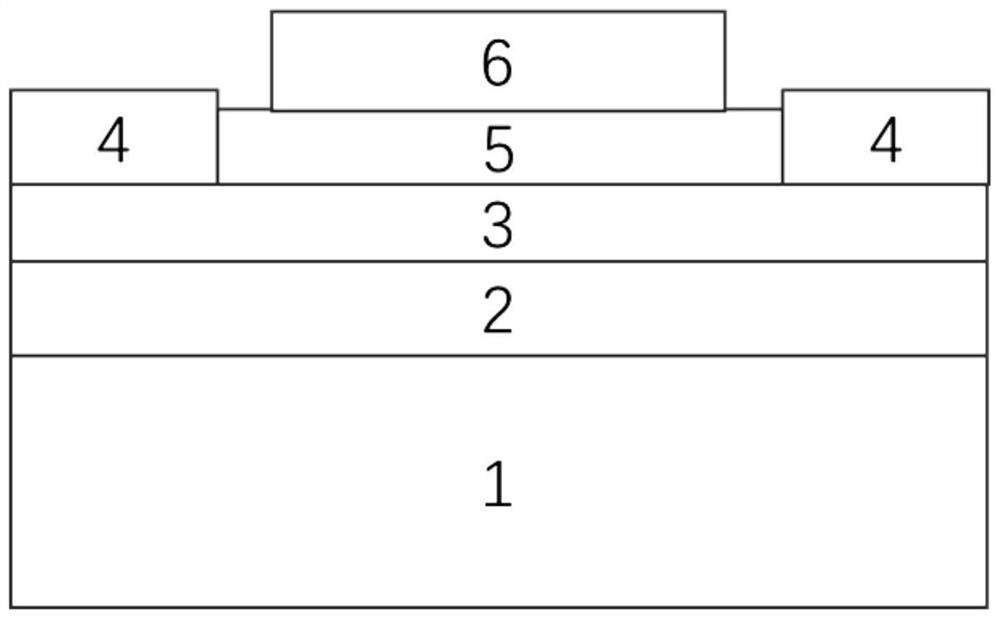

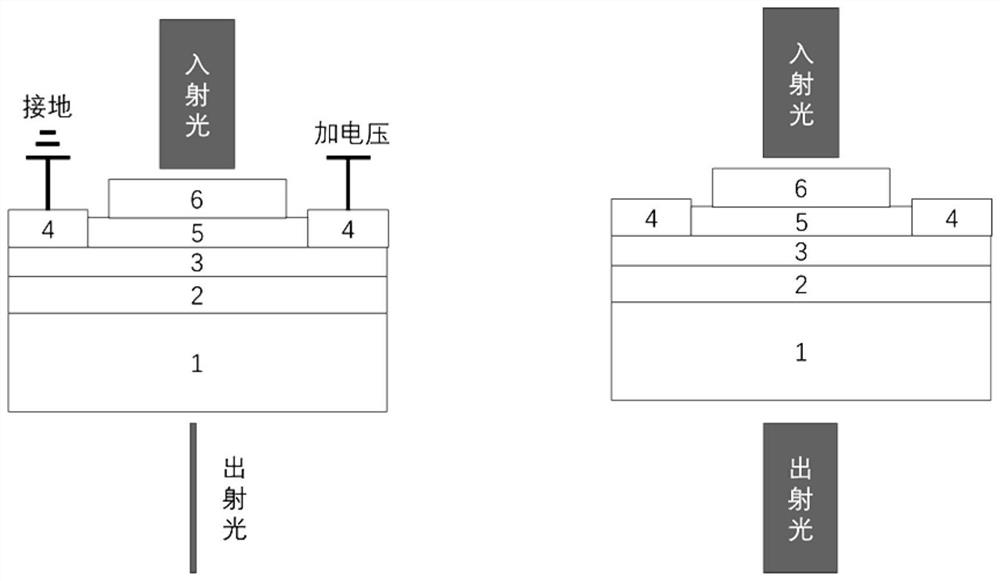

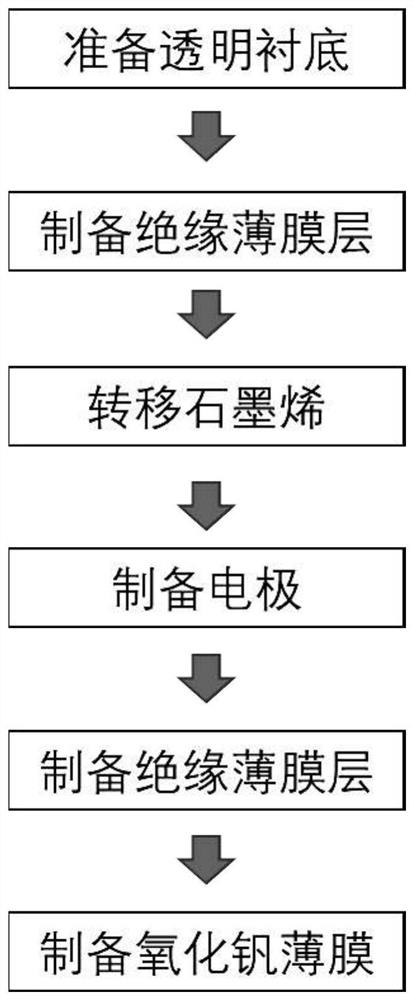

[0025] This embodiment provides a graphene-assisted vanadium oxide thermo-optic modulator, such as Figure 1-2 , comprising a substrate 1, a first insulating layer 2 formed on the substrate surface 1, a graphene layer 3 arranged on the first insulating layer 2, a second insulating layer 5 formed above the graphene layer 3, the The graphene-assisted vanadium oxide thermo-optic modulator also includes a metal electrode 4 deposited on the graphene layer 3 by photolithography or deposited on the second insulating layer by magnetron sputtering, reactive ion sputtering or deposited metal and then oxidized. 5 above the vanadium oxide film layer 6 .

[0026] The substrate is quartz, the first insulating layer is an ALD aluminum oxide layer with a thickness of 10-50nm, the second insulating layer is an ALD aluminum oxide layer with a thickness of 10-20nm, and the thickness of the vanadium oxide film layer is 50-200nm.

[0027] The metal electrode includes an adhesion layer in contact...

Embodiment approach 2

[0031] This embodiment provides a graphene-assisted vanadium oxide thermo-optic modulator, such as Figure 4 , comprising a substrate 1, a first insulating layer 2 formed on the surface of the substrate 1, a graphene layer 3 arranged on the first insulating layer 2, a second insulating layer 5 formed above the graphene layer 3, the graphite The ene-assisted vanadium oxide thermo-optic modulator also includes a metal electrode 4 deposited on the graphene layer 3 by photolithography or deposited on the second insulating layer 5 by magnetron sputtering, reactive ion sputtering or deposited metal and then oxidized. Vanadium oxide thin film layer 6 above.

[0032] The substrate is a silicon material, the first insulating layer is an ALD aluminum oxide layer with a thickness of 10-50nm, the second insulating layer is an ALD aluminum oxide layer with a thickness of 10-20nm, and the thickness of the vanadium oxide film layer is 50-200nm.

[0033] The metal electrode includes an adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com